Choosing the right molded door skin can make or break the durability and appeal of your door. Many builders get confused by the range of material options. Don’t worry — in this article, I’ll break down each type clearly so you can make better buying decisions with confidence.

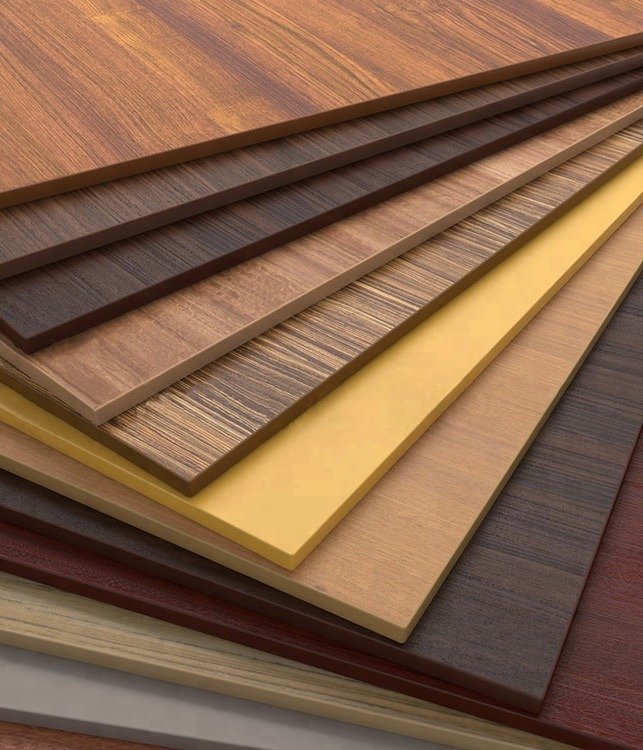

Molded door skins are typically made from MDF (Medium-Density Fiberboard), HDF (High-Density Fiberboard), plywood, wood veneers, laminates, and melamine. These materials are engineered using resins, heat, and pressure to replicate classic door panel designs affordably. Each material offers unique benefits in terms of cost, strength, appearance, and paintability, making them ideal for interior door applications.

Now that you know the basics, let’s explore what makes each material stand out — from performance to pricing — and how to choose the right one for your next build.

What Are Door Skins Made Of?

Door skins — the visible face of the door — come in different materials based on cost, appearance, and strength. Here’s what’s commonly used:

MDF (Medium-Density Fiberboard)

MDF stands for Medium-Density Fiberboard. It is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibers, combining them with wax and resin binders, and forming panels by applying high temperature and pressure.

- Made from compressed wood fibers and resin

- Easy to paint, smooth finish

- Affordable and widely available

- Best for: Budget-friendly interior doors

HDF (High-Density Fiberboard)

HDF is made by compressing wood fibers (usually from hardwoods) with resin under higher pressure and temperature than MDF, resulting in a much denser board—typically over 800–900 kg/m³ (compared to MDF’s 600–800 kg/m³).

- Similar to MDF but denser and more durable

- Ideal for high-traffic areas

- Best for: Premium molded door skins

Plywood

Plywood is a manufactured wood panel made by gluing together multiple thin layers (or “plies”) of wood veneer, with the grain of each layer typically rotated 90 degrees from the previous one. This cross-graining technique gives plywood its strength and stability.

- Made of wood veneer layers glued together

- Stronger and more moisture-resistant than MDF

- Best for: Flush doors or hybrid constructions

Wood Veneer

Wood veneer is a thin slice of real wood, usually less than 1/8 inch (about 3 mm) thick, that is typically glued onto a core panel such as MDF, HDF, particleboard, or plywood to give the appearance of solid wood.

- Thin layers of real wood over a composite base

- Offers a premium, natural wood look

- Best for: Decorative doors

Laminates

Laminates are synthetic or composite materials made by bonding multiple layers of paper or fabric with resin (usually melamine) under high pressure and temperature. The top layer is a printed decorative surface, often designed to look like wood, stone, or other textures.

- Synthetic finishes bonded onto MDF or HDF

- Durable, easy to clean

- Best for: Modern interiors and commercial doors

Melamine

Melamine is a synthetic material made from a combination of melamine resin and paper, used widely in furniture, cabinetry, and decorative panels. When people refer to “melamine,” they usually mean melamine-coated boards (like melamine-faced MDF or particleboard), not just the raw chemical.

- A ready-to-install plastic laminate surface

- Tough, stain-resistant

- Best for: Factory-finished, economical doors

PVC vs Melamine?

At UWG, we commonly use PVC and melamine as raw materials for surface finishing in door, cabinet, and wall panel production.

PVC (polyvinyl chloride) is a synthetic plastic polymer known for its excellent moisture resistance, flexibility, and easy cleaning. It’s ideal for bathrooms, kitchens, and humid environments due to its waterproof properties.

On the other hand, melamine is a thermosetting resin applied as a decorative coating over materials like MDF or particleboard. It offers a hard, scratch-resistant, and cost-effective surface, making it suitable for dry indoor areas such as living rooms and bedrooms.

The main difference lies in their performance and appearance: PVC is more durable against moisture and easier to apply on curved surfaces, while melamine has a more natural wood-like texture but is less resistant to water.

| Feature | PVC (Polyvinyl Chloride) | Melamine |

|---|---|---|

| Material Type | Thermoplastic polymer | Thermosetting resin over decorative paper |

| Appearance | Smooth or embossed, available in various colors/textures | Matte or textured finish, often woodgrain printed |

| Moisture Resistance | Excellent – fully waterproof | Moderate – water-resistant but not waterproof |

| Scratch Resistance | Good | Excellent |

| Heat Resistance | Moderate | Good |

| Durability | High flexibility, resistant to impact | Hard surface, but brittle under strong impact |

| Suitable For | Kitchens, bathrooms, high-moisture areas | Living rooms, offices, bedrooms, low-moisture areas |

| Design Flexibility | Easily molded into curves or 3D shapes | Best for flat surfaces and simple profiles |

| Cost | Generally higher than melamine | More budget-friendly |

Door Skin Material Comparison Chart

| Material | Appearance | Strength & Durability | Moisture Resistance | Surface Finish Options | Cost | Common Use Cases |

|---|---|---|---|---|---|---|

| MDF | Smooth, uniform, paintable | Moderate | Low | Paint, primer | ★ | Molded door skins, interior doors, budget furniture |

| HDF | Denser and smoother than MDF | Good | Low | Paint, primer | ★★ | High-precision molded door skins, flooring underlayment |

| Laminates | Printed finish (wood, stone, solid) | Good | Moderate | Pre-finished decorative layer | ★★ | Cabinets, modern interior doors, high-traffic commercial use |

| Wood Veneer | Real wood grain, natural texture | Good | Moderate (sealed) | Stain, clear coat | ★★★★ | Premium doors, furniture, luxury interior finishes |

| Plywood | Layered grain, natural look | Very Good | Good (depends on grade) | Paint, veneer, laminate | ★★★ | Door cores, structural panels, flush doors |

| Melamine | Solid color or wood-look printed | Moderate | Moderate | Pre-finished surface | ★★ | Economical doors, closets, cabinet interiors |

| PVC | Smooth or embossed, flexible | Good | Excellent (100% waterproof) | Pre-finished surface | ★★★ | Bathroom doors, kitchen doors, curved panels, humid areas |

How Builders Can Choose the Right Door Skin Material: A Practical Guide

As a builder, choosing the right door skin material is essential to balance cost, performance, and design. This guide will walk you through the common door skin materials, their advantages, and how to choose based on your project needs.

How to Choose Based on Project Needs

| Project Type | Recommended Door Skin | Why |

|---|---|---|

| Budget Housing | Molded HDF | Cost-effective, easy to paint |

| Luxury Residential | Wood Veneer | Natural look, premium appearance |

| Wet Areas (Bathrooms) | PVC or Laminated Skin | Moisture-resistant, low maintenance |

| High Traffic (Offices) | Laminated or HDF | Durable, easy to clean |

| Fire-Rated Requirements | Magnesium Oxide / FR-rated | Meets safety codes |

Choosing the right door skin is about matching materials to the environment and user expectations. As a builder, you must consider factors like durability, appearance, moisture exposure, fire rating, and budget.

Summary

There’s no one-size-fits-all answer — each molded door skin material serves a different need. At UWG,we specialize in manufacturing and supplying a wide range of door types with different skins—from cost-effective molded options to high-end veneer and fire-rated solutions. Let us help you find the right fit for your next project.