In the current construction market, builders face a dual challenge: material prices continue to rise while client expectations for quality remain high. According to industry analyses, materials can account for 40% or more of total project costs, and even small percentage changes can significantly impact profitability. This reality has driven many small and mid-sized builders to seek reliable, cost-efficient supply chain partners who can deliver both savings and uncompromising quality.So, how do we manage to help our clients save at least 20% on their procurement costs?

How We Achieve Cost Savings Without Sacrificing Quality?

We help builders save 20%–50% on procurement costs by combining factory-direct pricing, consolidated product sourcing, and streamlined logistics into one efficient process. Our factories manufacture for leading global retailers such as Home Depot, Menards, and Bunnings, which means every product meets strict quality standards trusted by millions of customers. All raw materials are purchased through a unified procurement system, ensuring consistent quality across doors, cabinets, flooring, and mouldings.

Because we manage the entire process from blueprint to installation, we also eliminate many hidden costs—miscommunication between suppliers, shipment delays, and compatibility issues between products. Here’s how we make it work in detail:

1. Optimized Production for Flexible and Fast Delivery

We operate dedicated production lines for different product categories, enabling us to run large-scale batches efficiently. When order volumes surge, other production lines can be switched over to assist. This flexibility allows us to adjust based on order complexity, production time, and required quantities—keeping lead times short while maintaining precision.

For example, when our Kentucky client placed a multi-category order, we reallocated capacity across lines so that doors, cabinets, and flooring were all completed within a unified shipping schedule.

2. Strategic Inventory Management

We maintain steady stock of 5,000 cubic meters of New Zealand radiata pine and 1,000 cubic meters of MDF to support immediate production. Additional materials are sourced only when orders are confirmed, which means we carry almost no unnecessary inventory—eliminating overstock and avoiding material degradation over time.

This lean approach not only reduces warehousing costs but ensures every project is produced with fresh, high-quality raw materials.

3. Maximized Shipping Efficiency

Every container is loaded to full capacity using our proprietary calculation system, ensuring no wasted space and no wasted money. We work with long-term freight partners—many of whom also serve Home Depot and Bunnings—which gives us competitive rates and reliable shipping schedules.

Our integrated approach means production completion dates are synchronized with vessel departures, reducing port storage fees and avoiding costly delays.

4. Source-Direct Advantage

We are the factory. There are no middlemen between us and our clients. By removing wholesalers and distributors from the chain, we avoid multiple layers of markup and communication gaps, passing those savings directly to builders.

5. Quality You Can Trust

Our quality assurance process starts at the material level, controlling wood moisture content at an optimal 6–8% to ensure dimensional stability. Each order passes through three rounds of inspection before shipment, with batch sampling and rework if needed. Third-party inspections are also available on request.

Our operations are certified by FSC, CARB, CE, UL, and SGS, meeting international standards for sustainability, safety, and compliance.

6. Rapid and Reliable Sample Process

We ship samples within 8 days from request to delivery. For our West Virginia client purchasing shaker doors, we sent corner samples to demonstrate joinery and finish. For our Kentucky client, we sent flooring planks, cabinet panels, and moulded door samples for review before confirming the full order.

7. End-to-End Project Support

We manage every stage from blueprint to installation:

- Blueprint Analysis – Engineers review plans to determine specifications

- Product List & Quotation – Complete bill of materials with transparent pricing

- Sample Approval – Quality verification before production

- Production Scheduling – Optimized manufacturing slots

- Packing & Shipping – Full-load optimization and aligned vessel schedules

- Delivery & Installation – Coordinated arrival and professional installation support

Clients work with one dedicated point of contact, backed by a team of designers, production planners, inspectors, and logistics coordinators—ensuring deadlines are met, quality is consistent, and hidden costs are eliminated.

Real-World Results: Two Builders’ Stories

Let’s look at two real-world examples of how our model works in practice.

West Virginia – Shaker Doors A small builder in West Virginia needed a full 40HQ container of shaker doors. Before committing, his main concern was whether our quality would match what he was used to buying locally. We sent him shaker door corner samples so he could inspect the joinery, finish, and overall craftsmanship. We also provided a clear delivery timeline—45–60 days for production plus around 45 days for ocean freight—and assured him that our hinge and hole placements followed U.S. installation standards. Confident in what he saw, he placed the order. When the shipment arrived, he installed the doors without a single adjustment. They fit perfectly, looked identical to local products, and cost him only one-third of the Home Depot price—saving over 50% on this item alone.

Kentucky – Multi-Category Purchase A Kentucky builder came to us for a more complex project: two 40HQ containers of moulded doors, one 40HQ of cabinets, and one 40HQ of flooring. His concerns were broader—quality, lead time, and, most of all, installation, as he had no local crew for cabinets and flooring. To address quality doubts, we sent separate samples for each product category. To address timing, we provided the same detailed schedule we gave our West Virginia client. For installation, we offered a complete solution: a signed contract with our partnered crew in his area, backed by a firm completion guarantee and contingency plans for any delays. The order shipped and arrived on schedule. Installation went smoothly, and the builder reported that the process saved him nearly 48% in total material costs and eliminated weeks of coordination with multiple suppliers.

The Takeaway In both cases, the builders started with concerns that could have delayed or stopped the order. By combining sample verification, clear communication, and end-to-end support—including installation—we turned those concerns into confidence and delivered measurable savings without sacrificing quality.

Industry Trends: Why Our Model Works Now More Than Ever

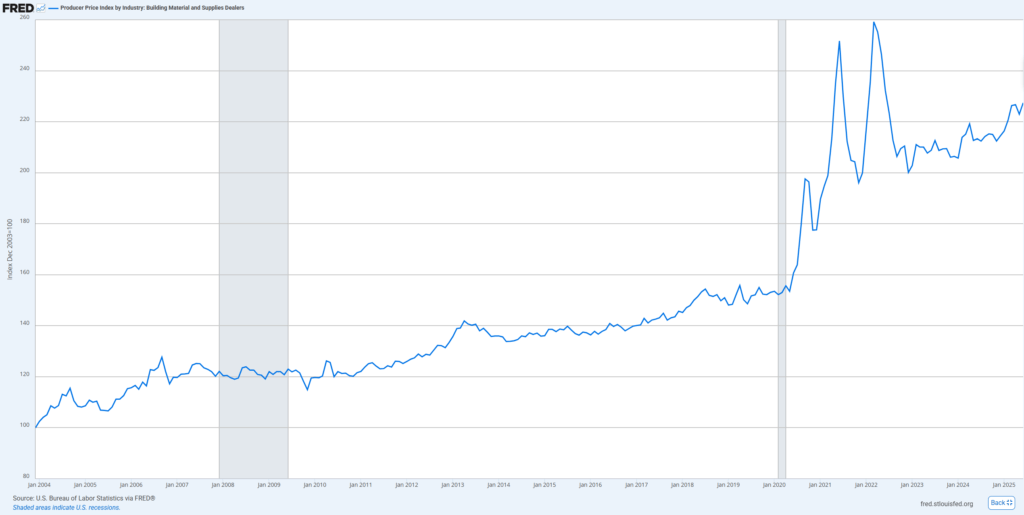

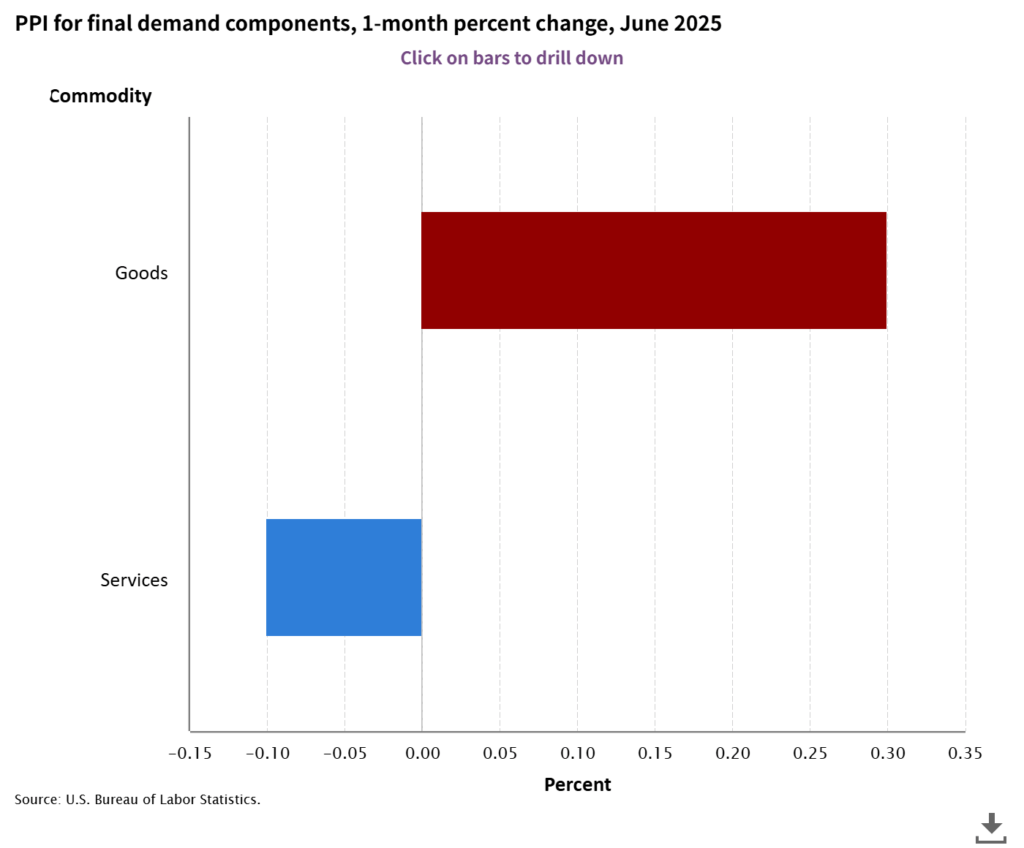

Builders today are still navigating elevated material costs, even as the sharp spikes of 2021–2022 have eased. According to the U.S. Bureau of Labor Statistics, the Producer Price Index (PPI) for final demand rose 2.3% over the year ended June 2025. Prices for key construction categories such as metals climbed 4.2%, while concrete and related products rose 5.6% in the same period. Lumber prices remain volatile—slightly lower than last year but still 15–18% higher than in 2019.

While local sourcing offers shorter transport times, it often comes with higher costs, inconsistent supply, and limited variety. International direct sourcing—when paired with strong logistics, quality control, and communication—can deliver both cost savings and consistent quality. With freight rates stabilizing and U.S. construction spending still exceeding $2 trillion annually, consolidating purchases with a single trusted partner has become one of the most effective ways for small and mid-sized builders to protect margins and remain competitive.

Conclusion

In a market where cost control and quality assurance are equally critical, we help builders achieve both. Our integrated production, delivery, and support model allows clients to save 20%–50% on materials while receiving products that meet the same standards as those sold by major retailers. By reducing hidden costs, simplifying procurement, and guaranteeing quality, we give builders a sharper competitive edge and a smoother project execution from start to finish.