Choosing between laminated veneer lumber (LVL) and plywood can confuse even seasoned builders. The wrong pick could compromise strength, increase costs, or delay timelines. This guide clears up the differences—helping you choose the right material for structural performance, cost, and efficiency.

Understanding how each product is made and performs will help you integrate the right material into your construction workflow.

What is LVL and Plywood?

Laminated Veneer Lumber (LVL)

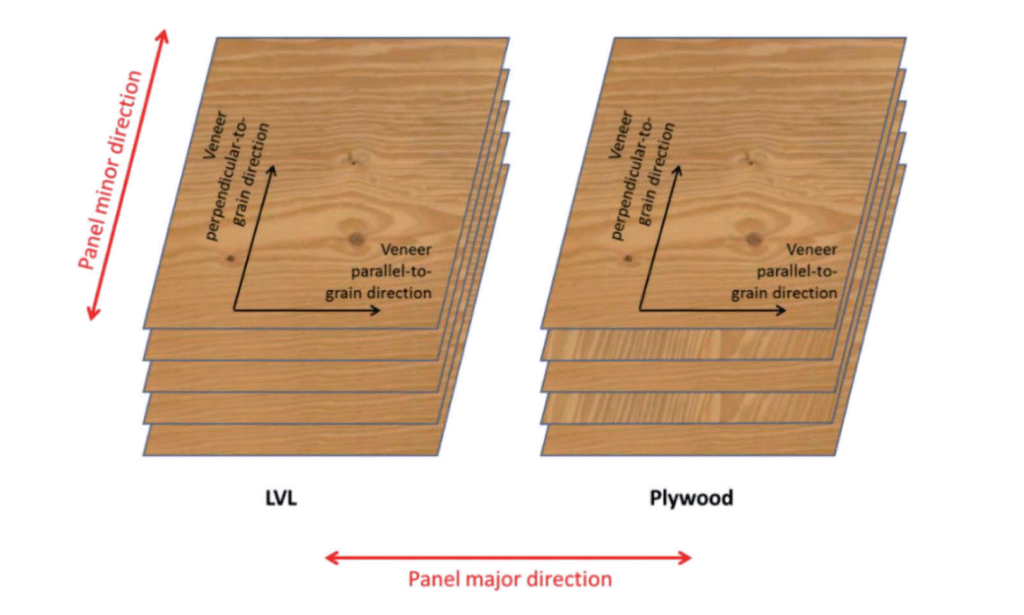

Laminated Veneer Lumber (LVL) is an engineered wood product made by bonding thin layers of wood veneers together with adhesives, with all veneers aligned in the same grain direction. This uniform orientation maximizes strength and stiffness along the length of the member, making LVL ideal for:

- Stair stringers

- Beams and headers

- Rim boards

- Truss chords

Key Benefits of LVL:

- Superior load-bearing capacity

- High dimensional stability

- Long continuous lengths available

Plywood

Plywood is an engineered wood panel made by bonding multiple layers of wood veneers together with adhesives, with the grain direction of each adjacent layer rotated—usually at a 90° angle. This cross-grain construction provides balanced strength, reduced shrinkage and expansion, and greater dimensional stability.

Common Uses of Plywood:

- Wall and floor sheathing

- Furniture and cabinetry

- Roof decking

- Decorative paneling

Advantages of Plywood:

- Lightweight and easy to handle

- Cost-effective

- Versatile for multiple applications

LVL vs Plywood: Manufacturing Process

| Step | Laminated Veneer Lumber (LVL) | Plywood |

|---|---|---|

| 1. Log Selection & Preparation | High-grade logs are debarked and conditioned (soaked/steamed) for uniform veneer quality. | Peeler logs are debarked and conditioned to improve flexibility for peeling. |

| 2. Veneer Peeling | Veneers are rotary-peeled into thin sheets of consistent thickness. | Same rotary peeling process to produce thin veneers. |

| 3. Veneer Drying | Veneers are dried to a specific moisture content for maximum bonding strength. | Veneers are dried to ensure proper adhesive penetration and bonding. |

| 4. Adhesive Application | Structural-grade adhesives (often phenol-formaldehyde) are applied to all veneers. | Adhesives (urea-formaldehyde or phenol-formaldehyde) are applied between veneer layers. |

| 5. Veneer Orientation | All veneers are aligned with the grain in the same direction for maximum strength along one axis. | Veneers are stacked with alternating grain directions (usually 90°) for balanced strength in both directions. |

| 6. Assembly & Pressing | Veneers are assembled and hot-pressed under high heat and pressure to form long, continuous billets. | Veneers are assembled and hot-pressed into flat panels. |

| 7. Cutting & Finishing | LVL billets are cut to size (beams, headers, rim boards) and may receive edge sealing for moisture protection. | Panels are trimmed, sanded, and sometimes surface-treated for specific applications. |

Physical Properties Comparison

When comparing lvl wood to plywood, the first thing to note is structural performance.

- Strength: LVL is stronger due to unidirectional grain alignment.

- Stability: LVL has minimal warping or shrinking.

- Weight: Plywood is usually lighter and easier to handle manually.

- Moisture resistance: Both are vulnerable without treatment, but marine-grade plywood resists moisture better in exposed applications.

Engineered for strength, laminated veneer lumber performs best in structural framing, while lvl plywood serves well in general construction.

Common Applications

LVL is widely used for:

- Beams and headers

- Rim boards

- Truss chords

- Stair stringers

Because of its strength and load capacity, lvl beam products are common in framing, especially where long spans are required.

Plywood is commonly used in:

- Wall and floor sheathing

- Furniture and cabinetry

- Roofing

- Decorative paneling

Its versatility and cost-effectiveness make it a go-to choice for builders and wholesalers.

Cost & Availability

- LVL is generally more expensive per linear foot than plywood due to its manufacturing process and strength.

- Plywood is more widely available and cheaper per square foot, making it ideal for cost-sensitive projects.

Large distributors often stock lvd plywood and LVL in various grades and thicknesses. However, for structural-grade LVL, lead times can vary depending on demand and region.

Pros & Cons Table

| Feature | LVL (Laminated Veneer Lumber) | Plywood |

|---|---|---|

| Strength | High – excellent for load-bearing | Moderate – depends on grade |

| Weight | Heavier | Lighter |

| Stability | Highly stable, low shrinkage | Stable with cross-grain construction |

| Cost | More expensive | More affordable |

| Applications | Beams, headers, structural framing | Sheathing, furniture, cabinetry |

| Custom Sizes | Available in longer lengths and depths | Standard sheet sizes |

Which One Should You Choose? (Buying Guide)

Choose LVL if:

- You’re building load-bearing components like lvl beams or rim boards.

- You need consistency and strength in longer spans.

- Budget is less of a concern than performance.

Choose Plywood if:

- You’re working on wall sheathing, subfloors, or cabinetry.

- You need affordable, easy-to-handle panels.

- You’re not dealing with high structural loads.

Also, if you’re wondering about the difference between veneer and laminate, veneer refers to thin slices of real wood, while laminate is typically a synthetic layer used for surface finishing—something entirely different from structural materials.

Frequently Asked Questions (FAQ) – LVL vs Plywood

1. What is the difference between LVL and plywood?

LVL has veneers aligned in one direction for high strength along its length, ideal for beams. Plywood has cross-grain layers, offering balanced strength for sheathing, furniture, and general construction.

2. Is LVL stronger than plywood?

Yes, LVL is stronger along its length and better for load-bearing applications. Plywood is strong but not for heavy structural loads.

3. Can plywood replace LVL for beams?

No. Plywood lacks the load-bearing capacity of LVL and may warp under heavy loads.

4. Which is easier to handle, LVL or plywood?

Plywood is lighter and easier to install. LVL is heavier and often requires machinery for long pieces.

5. Are LVL and plywood moisture-resistant?

Both need protection. Marine-grade plywood resists moisture better, while LVL requires edge sealing in exposed areas.

6. Can LVL and plywood be customized in size?

LVL is available in longer lengths and depths. Plywood comes in standard sheet sizes but can be cut to fit.

7. When should I choose LVL over plywood?

Choose LVL for beams, headers, rim boards, and structural framing. Use plywood for sheathing, subfloors, furniture, and cabinetry where cost and versatility matter.

Summary

Both LVL and plywood serve important but distinct roles in construction. LVL is your go-to choice when heavy-duty structural strength, dimensional stability, and long-span performance are non-negotiable—perfect for beams, headers, and other load-bearing applications. Plywood, on the other hand, shines as a versatile, budget-friendly option that works well for sheathing, subfloors, furniture, and countless general-purpose tasks.

The key is aligning your material choice with your project’s unique demands—whether that means maximizing strength, optimizing cost, or balancing both. The right decision at the start can save you time, reduce waste, and prevent costly rework down the line.

If you’re unsure which to choose, don’t leave it to guesswork—let’s talk about your project specs and get it right from day one.