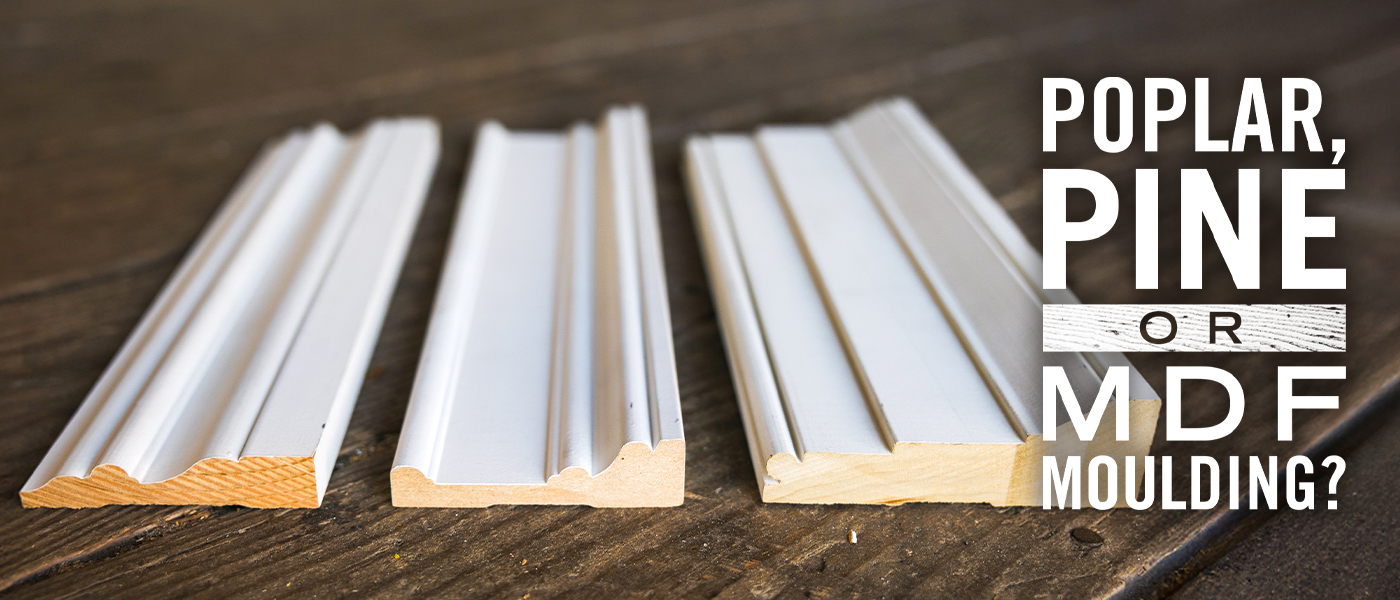

Choosing the right material for interior mouldings can be overwhelming — especially when price, durability, and ease of installation all matter. If you’re a builder or wholesaler, picking the wrong product could lead to callbacks or customer dissatisfaction. Let’s break down the most popular trim materials and help you make smarter decisions.

The most popular materials for interior moldings include MDF, solid wood, and LVL. MDF is economical, easy to cut, and paint, making it suitable for high-volume projects. Solid woods like oak, pine, and maple offer a natural look and high strength, making them suitable for dry or high-traffic areas. LVL (laminated veneer lumber) offers excellent stability and resistance to warping, making it suitable for long, straight skirtings or cornices, and it can be painted evenly. Meanwhile, for humid environments like bathrooms, kitchens, and basements, PVC is an option. It is moisture-resistant, mildew-resistant, and corrosion-resistant, while also being lightweight and easy to work with, making it suitable for a variety of styles.

Let’s explore these materials in depth so you can compare their strengths, weaknesses, and ideal applications.

What is the best material for interior trim?

The “best” material depends on what matters most for your project — cost, durability, moisture resistance, or ease of installation.

MDF (Medium-Density Fiberboard): is one of the most common choices for interior trim, especially for builders working on large-scale developments. It’s budget-friendly, easy to cut, and delivers a smooth surface ideal for painting. However, MDF doesn’t handle moisture well, making it unsuitable for bathrooms or damp environments.

Wood: like oak, pine, poplar, or maple—is the go-to for high-end applications. Wood offers unmatched strength and a premium appearance, especially for stained finishes. Red oak is a favorite for durability and style, while pine and poplar offer good value for painted trim.

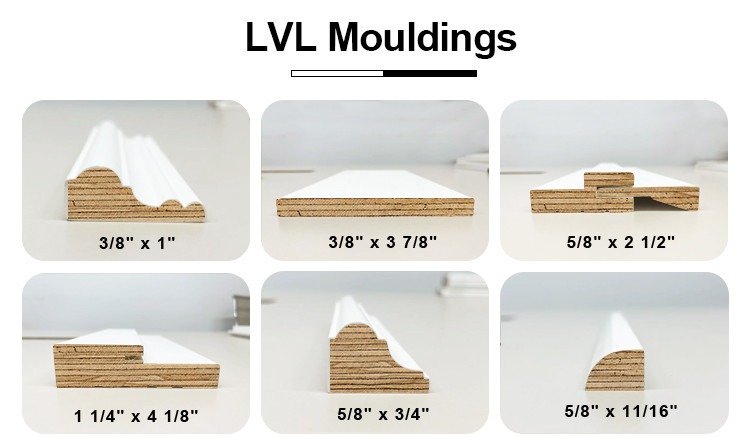

Laminated Veneer Lumber (LVL) is a top choice for interior trim due to its strength, stability, and resistance to warping. Unlike solid wood, LVL maintains its shape over time, making it ideal for long, straight runs in baseboards or crown molding. It also takes paint and finishes evenly.

Ultimately, there’s no single “best” trim material. It’s about matching the right material to the project’s environment, budget, and design goals. If you’re sourcing for a high-traffic or luxury space, wood is your go-to. For speed and cost, MDF delivers. LVL is ideal for interior trim applications that demand high strength and dimensional stability, such as door casings, window trims, and long-span baseboards or crown moldings.

What type of wood is used for interior trim?

Wood is still one of the most traditional and durable options — Solid wood lines are usually finger-jointed,especially in custom builds and upscale interiors. Here are the top choices:

- Pine: Lightweight, budget-friendly, and easy to work with.

- Oak (red or white): A hardwood that resists dents and adds visual warmth. More expensive but worth the investment.

- Maple: Dense and smooth, great for paint or stain.

- Poplar: Affordable and smooth, often used in painted trim.

Tip: If your clients care about long-term value, natural wood trim offers that premium feel that MDF can’t match.

Is MDF or wood better for baseboards?

Let’s compare them directly:

| Feature | MDF | Wood |

|---|---|---|

| Cost | Lower | Higher |

| Paint Finish | Excellent | Great (but needs priming) |

| Durability | Moderate | High |

| Moisture Tolerance | Poor | Depends on wood species |

| Availability | Readily available | Depends on region |

MDF and wood both have advantages, depending on your project’s needs. MDF is more affordable, easy to paint, and ideal for smooth, consistent finishes—making it popular in new builds and large-scale developments. However, it’s not moisture-resistant and can swell or warp in humid environments. Wood, especially hardwoods like oak or maple, is more durable and better suited for high-traffic or moisture-prone areas. While it costs more, wood offers long-term value and a premium look, especially when stained. For painted baseboards in dry areas, MDF is cost-effective. For durability, wood is the better long-term investment.

Are there moisture-resistant moulding materials?

Absolutely. If you’re working in areas with high humidity or water exposure, stick with:

PVC

PVC (Polyvinyl Chloride) is one of the most effective moisture-resistant moulding materials available today. Unlike traditional wood trim, PVC is completely impervious to water, making it ideal for areas exposed to high humidity or direct moisture — such as bathrooms, kitchens, basements, or even exterior applications.PVC moulding doesn’t swell, rot, or warp when exposed to moisture, and it’s also resistant to mold and mildew growth, which is a common concern in damp environments. This durability makes it a favorite among builders and homeowners looking for low-maintenance solutions without compromising appearance.Another advantage of PVC trim is its versatility — it can be shaped, routed, and cut just like wood, and it’s available in a range of styles to match traditional or modern interiors. Most PVC mouldings come pre-finished in white, but they can also be painted with 100% acrylic latex paint to match any décor.

How to compare interior trim materials for durability and cost?

When comparing, consider:

- Initial cost

- Labor time

- Durability in specific environments

- Appearance (paint vs. stain preference)

- Availability in bulk

| Material | Durability | Cost | Moisture Resistance | Use Case |

|---|---|---|---|---|

| MDF | Moderate | Low | Poor | Painted trim, high volume |

| Wood | High | High | Medium | Upscale homes, stain-grade |

| PVC | High | Medium | Excellent | Wet areas |

| LVL | Moderate | Medium | Excellent | Wet lands |

What trim material is best for bulk orders and ease of installation?

Wholesalers and builders often need:

- Cost-effective

- Easy to store

- Fast to install

Your best bets:

MDF: Affordable, widely available, and smooth to cut. For bulk pricing, MDF wins.

Summary

Choosing the right interior moulding material depends on where it’s going, how much you’re ordering, and what your clients want. From MDF to polyurethane, every material has its ideal use. For bulk orders or advice, don’t hesitate to contact your local supplier or distributor for the best pricing and availability. If you have any questions, feel free to contact me.