In large-scale multi-family construction, the sheer volume of units magnifies every inefficiency. Door installation—often repeated hundreds of times across a project—can become a critical bottleneck that delays inspections, disrupts finish schedules, and escalates labor costs. Without a scalable system, even small inconsistencies compound into rework, wasted time, and missed milestones.

To increase door installation speed by up to 50% in multi-family projects, apply three key strategies: adopt prehung door systems to eliminate on-site assembly, deploy professional-grade tools to ensure consistent installation quality, and enforce standardized workflows across all crews. These methods reduce human error, shorten labor cycles, and improve overall project reliability—especially at scale.

Let’s explore each of these strategies in detail and how you can apply them across active and future job sites.

Switch to Prehung Doors and Cut Install Time in Half

In multi-family construction, door installation isn’t just a finishing detail—it’s a critical path activity that directly affects the project’s close-out timeline, inspection readiness, and revenue recognition. The more units you’re building, the more installation bottlenecks can ripple across trades and scheduling. That’s why prehung doors are more than a time-saver—they’re a strategy.

What Are Prehung Doors—And Why They Matter at Scale?

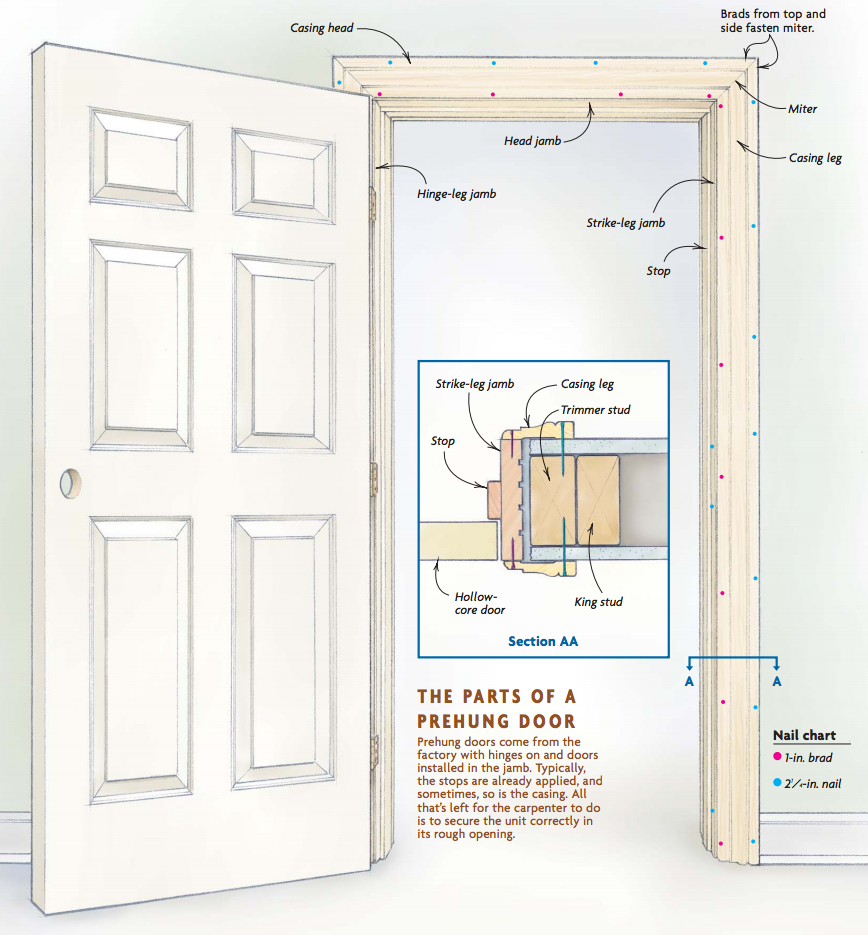

A prehung door unit is a factory-assembled package: the slab is already mounted within a frame, hinges pre-installed, with optional bore prep, weather seals, and thresholds. It’s built to spec—usually for standard 3-0 x 6-8 openings—but can also be ordered for fire-rated, ADA-compliant, and acoustical requirements.

For large-scale projects, this means:

- Reduced dependency on on-site millwork

- Fewer variables per door opening

- Faster QC and sign-off by inspectors

In many multi-family developments, a single door delay can stall mechanical, paint, flooring, or punch work in a unit—compounding into serious schedule drift.

Why Prehung Doors Drastically Reduce Labor Time

When using slab doors, installers must:

- Measure and align the rough opening

- Build or install the frame from scratch

- Mortise hinges manually—often with a jig

- Mount and align the door (± 1/8″ accuracy needed)

- Shim and level both vertically and horizontally

- Test swing, latch, and clearance

- Trim or adjust if misaligned

Each step compounds error and consumes time.

By contrast, prehung doors eliminate up to 60% of this complexity:

- Frames arrive square and plumb from the factory

- Hinge positions are factory-cut (ensuring uniformity)

- Slab-to-frame alignment is pre-verified

- Field crews simply position, shim, and fasten

This consistency reduces per-door install time from 45 minutes to 15–20 minutes, even when handled by general labor with basic training.

Time & Labor Comparison: Slab vs Prehung (Typical Site Conditions)

| Task | Slab Door (mins) | Prehung Door (mins) |

|---|---|---|

| Layout, measurement & adjustment | 10 | 2 |

| Frame installation / adjustment | 15 | 3 |

| Hinge cutting & slab mounting | 10 | 0 |

| Swing alignment & strike fitting | 10 | 5–10 |

| Final QA & touch-up | 5 | 3 |

| Total Time per Unit | 50 | 13–18 |

Over 100 units, this represents over 50 labor hours saved—roughly a full crew-week reclaimed.

Beyond Speed: Prehung Doors Support Compliance & Standardization

In regulated buildings—student housing, assisted living, senior communities—door assemblies often must comply with:

- NFPA 80 / 105 for fire-rated assemblies

- ANSI/BHMA A156 hardware standards

- ADA 404 for clear width and force limits

Using certified prehung units ensures field tolerance meets code from day one. You reduce the risk of inspector rejections due to:

- Improper hinge height

- Latch misalignment

- Non-compliant clearances or undercuts

Brands like ASSA ABLOY multi-family offer complete, pre-certified assemblies (including exit devices), streamlining both procurement and install.

Prehung Install Success Depends on Crew Consistency

While prehung doors simplify installation, they still require discipline to maximize ROI.

Key practices include:

- Pre-checking rough openings for plumb, level, and square before delivery

- Training all crews on consistent shimming techniques (e.g., 3-point shim at hinge, latch, and base)

- Standardizing anchor screw placement to avoid frame distortion

- Using install brackets or jigs to hold the frame square during fastening

Standardization Across Crews: From Chaos to Controlled Velocity

In projects with multiple install crews (or subcontractors), even minor variations in how doors are installed can lead to:

- Irregular gaps

- Failed inspections

- Rework across entire floors or buildings

Implementing a standard operating procedure (SOP) for prehung door installation ensures:

- Uniform swing direction matching plans

- Predictable door-to-floor clearances (especially critical before flooring goes in)

- Cleaner interface with other trades (framing, electrical, finish carpentry)

Tip: Print the SOP with diagrams, laminate it, and post it in every floor’s staging area. Use color-coded QC tags for each door: green = passed, yellow = punch needed.

🔧 What Tools to Standardize?

- Laser levels and cross-line lasers: For faster plumb checks

- Framing squares + install brackets: Keep the frame squared during fastener drive

- Collated shim kits: Reduce on-site measuring

- Screw pocket templates: Prevent over-tightening and bowing

With these tools + SOPs in place, even less experienced crews can complete 20–30 doors/day without callback risk.

⚠️ Without standardization, one bad install becomes a domino—misaligned hardware, non-compliant latch engagement, failed fire caulking. Standardization isn’t “nice”—it’s essential.

Speed Up Installations with the Right Tools (No Rework Needed)

Door installation is precision work. Unlike framing or drywall, even a 2–3mm misalignment in a door can cause swing issues, latch failures, or inspection delays. The right tools don’t just make installation faster—they prevent the costly rework that eats up crew time and affects handover schedules.

In large-scale multi-family projects, standardized tooling is critical to:

- Reduce variability between crews

- Maintain consistent plumb and reveal

- Accelerate throughput across units or floors

- Support training of new installers

Let’s break down which tools matter—and why.

🔧 Essential Tools That Eliminate Guesswork

- Door Hinge Jigs

Factory-calibrated templates that align hinge locations with precision. Use case: When modifying slab doors, this avoids measuring errors and uneven gaps. Savings: Prevents hinge misalignment that leads to door sag or binding.

- Pneumatic Nail Guns / Screw Guns

Faster and more consistent than hand driving fasteners—especially on jambs and shims. Use case: Attaching prehung frames to studs with minimal vibration or frame shift. Bonus: Reduces installer fatigue and speeds up repetition across dozens of units.

- Laser Levels (Cross-Line or Rotary)

Maintains plumb and level in real-time during install—especially critical for wider doors or double-door setups. Use case: Ensuring frame is not torqued by uneven flooring or bowed studs. Why it matters: Plumb errors >3° cause latching failures and door swing rebound.

- Adjustable Shims / Shim Guns

Faster than wood wedges. Pre-sized plastic shims ensure uniform spacing. Use case: Positioning the jamb evenly without cracking or splitting trim. Impact: Reduces guesswork and prevents bowing the frame during anchoring.

- Prehung Door Install Kits

Kits with centering straps or brackets that hold the frame square during fastening. Use case: Installing prehung doors solo or with reduced crew size. Value: Ensures squareness without needing a second pair of hands or clamps.

🧮 Time and Labor ROI: Do the Tools Pay Off?

Let’s say each tool saves 8–12 minutes per door, and you’re installing 200 doors on a project.

| Tool Investment | Time Saved | Labor Cost Saved |

|---|---|---|

| $300–$500 total | ~33 hours | ~$1,200–1,600* |

*Based on $40/hr crew rate

That’s a 3–5x return on investment—plus reduced callbacks, punchlist work, and happier inspectors.

🏗️ Who Manages Tooling and Training?

To maximize consistency across crews and job sites:

- Assign a site-level install supervisor to oversee tool readiness and maintenance

- Create a standard tool checklist per crew (or sub)

- Require tools during onboarding or safety briefings

- Use QR-code video links at toolboxes for on-demand training

Tools are only valuable if they’re used correctly—make training a default, not an afterthought.

Standardized Workflows = Consistent Speed, Fewer Errors, and Zero Surprises

Speed without consistency is chaos. In multi-family projects, where multiple crews might be working across units, floors, or even buildings, lack of process standardization leads to:

- Uneven install quality

- High punchlist rates

- Failed inspections

- Delayed project handover

One crew might install 20 doors a day, another just 12—with the same tools. The difference? Workflow discipline.

Every door install includes at least 6–8 micro-decisions—from shim position to screw order. Without a standardized approach, each crew brings their own style. That means:

📋 Why Standardization Drives Real Results

| Without Workflow | With Workflow |

|---|---|

| Latch misaligned by 3mm | Latch always centered on strike plate |

| Shim gaps left at head | 3-point shim on hinge, latch, base |

| Fasteners split jambs | Predrilled, spaced fasteners used |

| Slab binds on flooring | Prechecked undercut clearance |

Even 5–10% install failures across 100+ units can mean dozens of rework hours and thousands in cost.

🧱 Recommended Workflow (Field-Tested for Prehung Installs)

Here’s a proven, repeatable process you can enforce across all crews:

- Pre-Check

- Verify rough opening dimensions

- Confirm swing direction matches plan

- Check threshold level & wall plumb

- Positioning

- Insert prehung frame into opening

- Use temporary brackets or install straps to hold square

- Shimming

- Use 3-point shim: hinge-side, latch-side, base

- Cross-check with laser or spirit level

- Anchoring

- Secure with 3″ wood screws at hinge/latch locations

- Confirm jamb compression is even top-to-bottom

- Adjustment

- Open/close door 3x to confirm swing arc

- Verify latch alignment and reveal gaps (3/32” max variance)

- Finish

- Install casing or trim

- Final QC: Label door as “complete” or “needs punch”

🛠️ Tools needed: laser level, install brackets, color-coded shim packs, torque-limiting screw gun.

🧑🏭 Who Owns the Workflow?

Standardization only works when everyone is aligned—from the foreman to the newest apprentice. Here’s how to implement it:

| Role | Responsibility |

|---|---|

| Site Supervisor | Trains crew leads, approves first installs per floor |

| Crew Lead | Enforces SOP steps, signs off daily door log |

| Installer | Follows checklist, flags issues early |

| QC Tech | Verifies swing, clearance, latch action per unit |

💡 Pro Tip: Post laminated workflow sheets in staging areas. Use punch-free inspection tags (green = pass, yellow = rework) for fast tracking.

⚠️ Top Mistakes That Standardization Solves

- Over- or under-shimming causing frame deflection

- Latch misalignment from incorrect jamb positioning

- Swing clearance issues due to missed flooring height planning

- Out-of-plumb installs from rushed anchoring

These failures often only appear after finishing work, requiring full unit re-entry. A standardized process eliminates 90% of these surprises.

📲 Use Tech to Enforce the Process

Modern job sites are moving beyond clipboards. You can:

- Create mobile SOP checklists using tools like Fieldwire or Procore

- Set up QR codes on toolboxes linking to training videos

- Use daily install logs to spot bottlenecks or retrain weak crews

- Track first-time quality (FTQ) rate by crew or phase

Example: A client reduced rework by 34% in Phase 2 simply by enforcing digital checklists and requiring photo documentation of each shim/anchor step.

Final Word

Workflow isn’t bureaucracy—it’s your insurance policy. Standardize the process, train your people, and equip them to win. The result? Fewer callbacks, faster turnover, and crews who finish strong every time.

Summary

Efficient door installation in multi-family construction requires more than just speed—it demands consistency, quality control, and coordination across teams. By switching to prehung doors, equipping crews with specialized tools, and implementing standardized workflows, builders can reduce installation time by up to 50% while minimizing rework, inspection failures, and cost overruns. These improvements scale effectively across large projects, offering lasting gains in productivity and professional execution.