Introduction

Picture this: you’re standing on the job site of a high-end residential project. The client walks in, holding a design magazine, and points to a beautiful zigzag wood floor pattern. “This is what I want,” they say. You look closer and realize it could be one of two styles — herringbone or chevron.

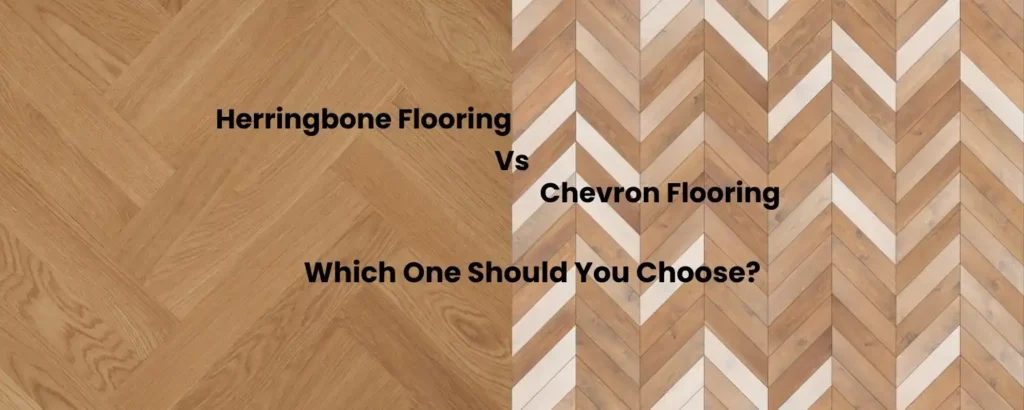

To the untrained eye, these two flooring patterns look almost identical — both create that classic “V” shape that adds movement and elegance to a room. But for builders, the difference goes far beyond appearance. The installation methods, material waste, cost, and even long-term durability can vary significantly between the two.

Understanding these distinctions is essential when helping clients choose the right flooring for their projects. In this article, we’ll break down the structural differences, installation considerations, and ideal applications for herringbone and chevron flooring — giving you the practical insight to make confident recommendations on site.

In short, herringbone and chevron differ in pattern structure, installation methods, and practical application. Herringbone uses rectangular planks arranged at right angles, creating a classic, textured appearance that’s easier and more cost-effective to install. Chevron, on the other hand, uses boards cut at precise angles to form seamless “V” points, resulting in a more modern, directional look — but with higher precision and labor demands. Choosing between them depends on your project goals: whether you prioritize traditional charm and efficiency, or a bold, high-end visual statement.

Understanding the Pattern and Structure

At first glance, herringbone and chevron floors share a similar “V” pattern, but their geometry and installation methods are fundamentally different — and these differences directly affect how they’re manufactured, installed, and perceived in finished spaces.

Herringbone flooring is created using rectangular planks laid in a staggered zigzag pattern, where the end of one board meets the side of another at a 90-degree angle. The result is a broken, interlocking effect that gives depth and texture to the floor. Because of its perpendicular alignment, herringbone can be installed with standard planks — there’s no need for custom cutting at specific angles. This makes it more forgiving during installation and less prone to visible gaps if the subfloor isn’t perfectly level.

In contrast, Chevron flooring features boards cut at precise 45° or 60° angles at each end. When placed together, the ends form a continuous “V” without overlap, creating a cleaner and more symmetrical look. Chevron requires each plank to be factory-cut to match the exact angle, which means higher precision but also less tolerance for on-site adjustments.

From a design standpoint, the effect is distinct:

- Herringbone tends to look more traditional and textured, ideal for classic or vintage interiors.

- Chevron offers a sleeker, more contemporary feel — its sharp lines make rooms appear longer and more structured.

For builders, understanding this distinction helps in communicating clearly with designers and clients. A quick look at the plank ends usually reveals the pattern type — straight ends for herringbone, angled ends for chevron — a simple check that can prevent confusion during ordering and installation.

Installation, Cost, and Maintenance Comparison

While both herringbone and chevron floors add sophistication to a space, they differ significantly in how they’re installed — and those differences affect labor, materials, and overall project timelines.

Installation complexity is the first major factor. Herringbone is generally easier to install because it uses standard rectangular planks. The layout begins from a central reference line, and installers simply alternate directions to create the interlocking “V” pattern. However, precision is still critical: even a small deviation at the start can misalign the entire pattern. For engineered wood or SPC herringbone, many manufacturers now provide click-lock systems that speed up installation and minimize adhesive use.

Chevron, on the other hand, demands greater accuracy and more time. Because each board must align at an exact angle, installers need to maintain perfect alignment across the floor. The process often involves detailed layout drawings, precise measurements, and pre-checking every joint. Any variation in angle can break the visual flow, so even experienced flooring teams find chevron more demanding.

Material waste is another consideration. Herringbone can often make use of standard-length planks, which reduces cutting waste. Chevron planks, cut at angles, generate more offcuts and typically cost more per square foot due to the manufacturing precision required. This also translates to higher replacement costs if boards are damaged during or after installation.

When it comes to cost, herringbone generally offers better value. It uses simpler materials, requires less customization, and can be installed faster. Chevron, while more expensive in both material and labor, provides a high-end visual appeal that many designers and luxury homeowners are willing to pay for.

Maintenance for both patterns is similar — regular sweeping, occasional damp mopping, and immediate cleaning of spills. However, because chevron’s joints align in straight lines, dirt can sometimes accumulate more visibly along the seams, whereas herringbone’s staggered layout tends to hide imperfections better.

For builders, understanding these nuances helps in budgeting both time and cost. The choice between the two often depends on the project’s aesthetic goals, budget range, and installation schedule — all factors that can significantly influence the client’s final decision.

Choosing the Right Option for Your Project

Selecting between herringbone and chevron flooring isn’t just about aesthetics — it’s about aligning design intent, budget, and practicality with the project type. For builders, the best choice often depends on where and how the flooring will be used.

For residential projects, herringbone is often the safer and more flexible option. It adds visual interest to living spaces without feeling overly formal, and it works well with a variety of materials — from solid oak and engineered hardwood to SPC or laminate. Its forgiving installation process and lower material cost make it ideal for medium- to large-scale housing developments where cost control and schedule reliability are critical.

Chevron, on the other hand, shines in high-end or design-driven spaces — luxury apartments, boutique hotels, or commercial lobbies where the visual impression matters as much as durability. Its seamless “V” alignment creates a strong sense of direction and symmetry, visually elongating hallways or open spaces. For architects and designers seeking a statement look, chevron flooring delivers that upscale, tailored finish.

Builders should also consider room size and lighting. In smaller or darker rooms, herringbone’s broken pattern diffuses light and makes the space feel warmer and more balanced. In larger or well-lit areas, chevron’s sharp geometry enhances depth and draws the eye forward, emphasizing spatial flow.

When advising clients, it’s helpful to present both mockups or samples side by side. Clients often realize that the difference, while subtle in photos, becomes obvious in person — especially under natural lighting. Additionally, builders can suggest engineered or prefinished options to simplify installation and ensure color consistency across the project.

Ultimately, there’s no universal “better” pattern. The right choice depends on how each floor aligns with the overall design vision, budget, and construction timeline. What matters most is that the builder understands the technical and visual implications well enough to guide clients toward a flooring solution that balances all three.

Conclusion

Both herringbone and chevron flooring bring timeless elegance and value to interior spaces — but for builders, the key lies in understanding their technical and practical differences. Herringbone offers versatility, easier installation, and cost efficiency, making it ideal for large-scale or residential projects. Chevron, though more demanding in precision and price, provides a distinctive, high-end aesthetic suited for statement designs.

By weighing installation complexity, budget, and the overall design goal, builders can confidently recommend the pattern that best fits each project. In the end, both options reflect craftsmanship — and when installed correctly, either can turn an ordinary floor into the defining feature of a space.