Material choice in RTA cabinet construction directly affects strength, lifespan, and customer satisfaction. With MDF, plywood, and particle board dominating the market, how should professionals—cabinet fabricators, installers, and specifiers—navigate these options for optimal results?

Plywood offers the best overall performance for RTA cabinets due to its structural strength, moisture resistance, and fastening reliability. MDF is the most cost-effective option, ideal for painted finishes and often used for doors and panels. Particle board falls between the two in cost but offers limited durability, making it suitable only for low-stress, dry environments. Optimal material selection depends on part function, budget priorities, and environmental exposure.

Let’s examine how each material performs across real-world cabinet manufacturing priorities—structural integrity, workability, lifecycle cost, and compliance.

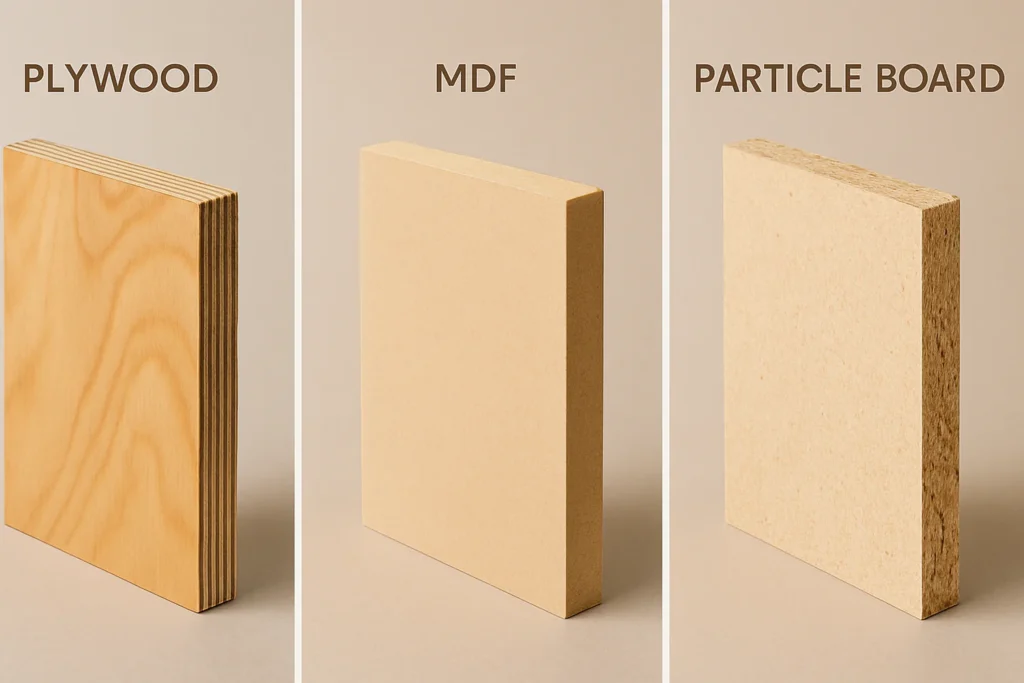

What Is MDF, Particle Board, and Plywood?

Before comparing materials for RTA cabinet construction, it’s essential to understand their manufacturing processes and performance characteristics.

- MDF (Medium-Density Fiberboard):Engineered from fine hardwood and softwood fibers bonded under high temperature and pressure with synthetic resin. MDF features a homogenous core, excellent machinability, and a smooth surface ideal for high-end paint finishes or vinyl wraps. However, its internal bond strength is moderate, and it lacks moisture resistance without proper sealing.

- Particle Board:Manufactured from larger wood particles, chips, and industrial sawdust, this board is bonded with urea-formaldehyde resin and pressed into sheets. It’s an economical option with limited structural performance. Particle board is commonly used in cost-sensitive cabinetry, particularly for non-load-bearing components or shelving.

- Plywood:Comprised of multiple thin veneer layers laid crosswise and bonded with exterior-grade adhesives (often phenol-formaldehyde). Its cross-laminated structure grants superior dimensional stability, enhanced screw-holding strength, and resistance to moisture and warping. Cabinet-grade plywood often comes in graded faces (A/B, B/C) and core types (veneer core, MDF core).

How Do MDF, Plywood, and Particle Board Perform in Cabinet Construction?

Let’s evaluate each material based on performance metrics relevant to cabinet fabrication and installation:

- Structural Integrity:Plywood has the highest load-bearing capacity and performs best under mechanical stress. It’s ideal for base units, wall-hung cabinets, and heavy-duty shelving.

- Moisture Resistance:Plywood (especially marine or exterior-grade) outperforms both MDF and particle board in humid environments. MDF can swell if unsealed, and particle board deteriorates rapidly when exposed to moisture.

- Machinability & Finishing:MDF offers superior paintability and clean machining for intricate profiles. Plywood can splinter during routing. Particle board lacks surface smoothness unless pre-laminated.

- Fastener Holding Strength:Plywood holds screws and dowels well due to its layered structure. MDF has moderate screw retention but can crumble under repeated adjustments. Particle board has poor fastener strength.

- Weight & Workability:MDF is denser and heavier than plywood, which can affect transport and installation. Particle board is light but brittle. Plywood offers a good balance of strength-to-weight ratio.

Where Does Each Material Fit in Cabinet Assembly?

Different parts of an RTA cabinet system impose different performance demands. Selecting the right material for each component ensures not just cost control, but also structural stability and long-term customer satisfaction.

| Cabinet Part | Best-Suited Material | Why |

|---|---|---|

| Cabinet Carcass | Plywood | High load-bearing capacity, moisture resistance, strong fastener retention. |

| Back Panel | Particle Board | Low-cost, non-structural; suitable for wall-facing installations. |

| Toe Kicks & Base | Plywood | Withstands floor-level moisture and repeated impact. |

| Cabinet Doors | MDF | Provides smooth surface for paint or foil finishes; easy to machine. |

| Drawer Bottoms | Particle Board | Cost-effective for non-load-bearing applications. |

| Face Frames / Rails | Solid Wood or Plywood | High rigidity and visual finish when exposed. |

📌 A material-agnostic cabinet design is rarely optimal—use-based selection is key.

Which Material Makes Installation Faster or Easier?

For contractors and assembly teams, material behavior during transport, machining, and installation matters just as much as performance specs.

- Plywood is relatively lightweight and holds screws reliably, reducing rework. However, its layered grain can cause splintering if tools are dull or improperly set.

- MDF machines very cleanly, ideal for CNC-milled doors, but is prone to edge chipping and weight-related handling issues on job sites.

- Particle Board is fragile during transport and corner fastening; without edge banding or sealing, it is vulnerable to breakage and delamination.

🛠 Field insight: Installers often prefer plywood carcasses paired with prefinished MDF doors for both stability and speed.

Are Cheaper Materials Actually More Expensive Over Time?

While particle board significantly reduces upfront material costs, its low durability and susceptibility to moisture damage can lead to premature failures, callbacks, or customer dissatisfaction—especially in kitchens and bathrooms.

- MDF, when properly sealed and used in dry applications, offers good longevity. But exposed edges can deteriorate if not protected.

- Plywood, although the most expensive per sheet, tends to offer the lowest lifecycle cost due to fewer failures, reduced repair needs, and better resale perception.

💡 Long-term cost = Material cost + Installation risk + Maintenance + Brand reputation impact

How Do Environmental Regulations Affect Material Choice?

Increasingly, material choice is shaped not only by performance, but also by compliance and sustainability.

- Formaldehyde Emissions: MDF and particle board are typically bonded with urea-formaldehyde resins. Many markets now require compliance with CARB Phase 2 or EPA TSCA Title VI standards for low formaldehyde emissions.

- Low-VOC Plywood & Alternatives: Exterior-grade plywood often uses phenol-formaldehyde, which emits less. Soy-based adhesives and NAF (No Added Formaldehyde) options are gaining traction.

- Green Certifications: LEED-compliant buildings and eco-conscious buyers often require low-emission, FSC-certified, or recycled-content materials.

🌿 Projects targeting sustainability or working in regulated markets must align with material documentation and certifications.

How to Choose the Right Material for Each Project Type

Choosing the right material isn’t just about performance—it’s about matching the right balance of durability, cost, appearance, and compliance to the project’s needs.

| Project Type | Recommended Material Strategy |

|---|---|

| High-End Custom Kitchens | Plywood carcass, MDF doors with lacquer or foil, solid wood accents |

| Multi-Family Housing | Plywood or HDF carcass, thermally fused laminate (TFL) doors |

| Budget Apartment Renovations | Particle board boxes (sealed), prefinished MDF fronts |

| Commercial Spaces | Moisture-resistant plywood or PVC-laminated MDF |

| Green Building Projects | FSC-certified plywood, NAF MDF, zero-VOC finishes |

Conclusion

Each material—plywood, MDF, and particle board—has a clear role in cabinet construction. The key is not choosing the “best” material, but the right one for each component and project type. For builders and fabricators, strategic material selection means better performance, smoother installs, and satisfied clients.