Engineered wood flooring has become one of the most popular choices for modern homes and commercial spaces. It offers the natural beauty of real hardwood while delivering superior stability, easier installation, and better performance in challenging environments. But what exactly is engineered wood flooring—and how does it differ from solid wood or laminate?

Engineered wood flooring is a multi-layered flooring product made of a top layer of real hardwood veneer bonded over a core of high-quality plywood or fiberboard. This structure increases stability, reduces sensitivity to moisture, and offers the aesthetic of solid wood at a lower cost.

How Is Engineered Wood Flooring Structured?

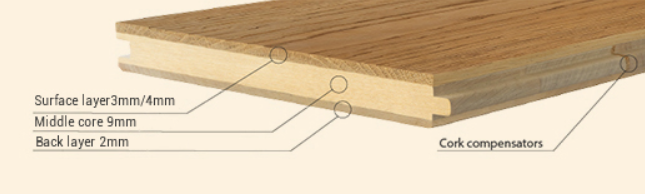

Engineered wood flooring is built from multiple layers, starting with a top veneer of real hardwood — oak, maple, hickory, or walnut — which provides the natural beauty. Beneath this surface, several layers of plywood or high-density fiberboard (HDF) are glued in a cross-grain pattern. This construction boosts structural integrity and minimizes expansion or contraction due to temperature and humidity changes.

Typical thickness ranges from ⅜” to ¾”, with wear layers varying between 0.6 mm and 6 mm, depending on quality and price point. Builders often prefer tongue-and-groove or click-lock systems for fast and reliable installation.

What Are the Benefits of Engineered Wood Flooring?

Engineered wood offers several benefits that make it ideal for builders and bulk buyers:

- Moisture resistance: Unlike solid hardwood, engineered wood can be installed in below-grade spaces like basements and over radiant heat systems.

- Cost efficiency: It provides the look and feel of hardwood at a lower price, helping stay within budget on large projects.

- Installation versatility: Can be nailed, stapled, glued, or floated.

- Eco-friendliness: Uses less slow-growing hardwood per plank, making it a more sustainable choice.

This is why it’s widely chosen for multi-unit residential buildings, commercial installations, and custom homes.

What Are the Limitations of Engineered Wood Flooring?

Despite its advantages, engineered wood does have limitations:

- Refinishing is limited: Thinner wear layers can’t be sanded down more than once or twice.

- Still vulnerable to heavy water exposure: While more moisture-resistant than solid wood, it’s not waterproof.

- Price sits between solid wood and laminate: It’s more expensive than laminate but usually more affordable than premium hardwood.

- Low-quality versions can delaminate: Avoid cheap imports with poor bonding or low-grade plywood.

Understanding these trade-offs helps in choosing the right product tier for different clients.

Types of Engineered Wood Flooring

There are various types, suited for different applications:

- Top veneer thickness: Thin (0.6–2 mm), medium (2–4 mm), and thick (4–6 mm+)

- Surface finishes:

- Brushed: rustic and textured

- Lacquered: smooth and glossy

- Oiled: natural and matte

- Core materials:

- Plywood core: more durable and stable

- HDF core: more cost-effective

- Edge styles: Beveled, square, or micro-beveled

- Locking systems: Traditional tongue-and-groove vs click-lock (ideal for DIY or floating installs)

Where Does Engineered Wood Flooring Work Best?

Builders love engineered wood for its flexibility. It’s perfect for:

- Basements and ground floors: Handles moisture better than solid wood

- High-humidity regions: Performs better in tropical or coastal climates

- Radiant heat systems: Stable under fluctuating temperatures

- Concrete slabs: Can be glued directly or floated with underlay

It’s also popular in condos, hotels, and retail spaces, where appearance and durability matter.

Engineered Wood vs. Solid Hardwood vs. Laminate

Engineered wood flooring combines the best of both worlds. It looks like solid hardwood because it has a real wood surface, but its plywood core makes it more stable and moisture-resistant. Solid hardwood is 100% wood, durable, and can be refinished many times, but it’s sensitive to humidity and more expensive. Laminate, on the other hand, is the most budget-friendly. It’s made of synthetic layers and doesn’t use real wood on the surface, so while it resists wear well, it lacks the authentic feel and can’t be refinished.

In short, engineered wood offers a balance: it’s more affordable than solid wood, more authentic than laminate, and performs better in varied environments.

Maintenance & Care Tips

Maintaining engineered wood is simple with the right practices:

- Sweep or vacuum weekly to remove dirt and grit

- Use a damp (not wet) mop with a hardwood-safe cleaner

- Avoid harsh chemicals and steam mops

- Place pads under furniture to prevent scratching

- Keep indoor humidity stable between 40–60%

For high-traffic areas, consider products with thicker wear layers or UV-cured finishes to minimize surface wear.

Summary

Engineered wood flooring combines real-wood beauty with enhanced stability, making it a reliable choice for modern homes and large-scale building projects. Its multi-layer construction delivers long-term durability, excellent dimensional performance, and compatibility with various installation environments, including condos, basements, and heated floors. With a wide range of species, finishes, and plank sizes, it gives builders, designers, and distributors the flexibility to achieve the look they want without compromising budget or performance.