Introduction: The Real Challenges Behind Global Procurement

In today’s construction industry, global sourcing is expanding rapidly—but so are the frustrations. Companies face rising material costs, unpredictable lead times, delayed shipments at ports, complex documentation requirements, and constant pressure to keep projects on schedule. Even teams with international experience can struggle to coordinate freight forwarders, customs brokers, duty payments, and last-mile delivery across multiple countries. For many projects, the risk of hidden fees and delays often overshadows the benefits of international purchasing.

By shifting logistics, customs clearance, duty handling, and final delivery responsibilities to the seller, DDP turns global procurement into a streamlined and predictable workflow. It simplifies budgeting with fixed, all-inclusive pricing, removes the need to manage customs paperwork, accelerates delivery to job sites, reduces compliance risks, and makes multi-SKU sourcing far easier. In short, DDP offers the simplest and most reliable path to international procurement: products delivered directly to your door, ready for installation.

What DDP Really Means — And Why It Matters in Construction Supply Chains

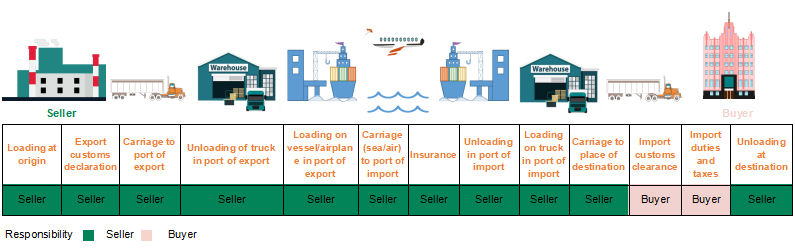

DDP (Delivered Duty Paid) is an Incoterm in which the seller takes responsibility for the entire logistics chain—from factory to the buyer’s warehouse or project site. This includes:

- Export procedures

- Ocean freight

- Import customs clearance

- Duties & taxes

- Domestic trucking delivery

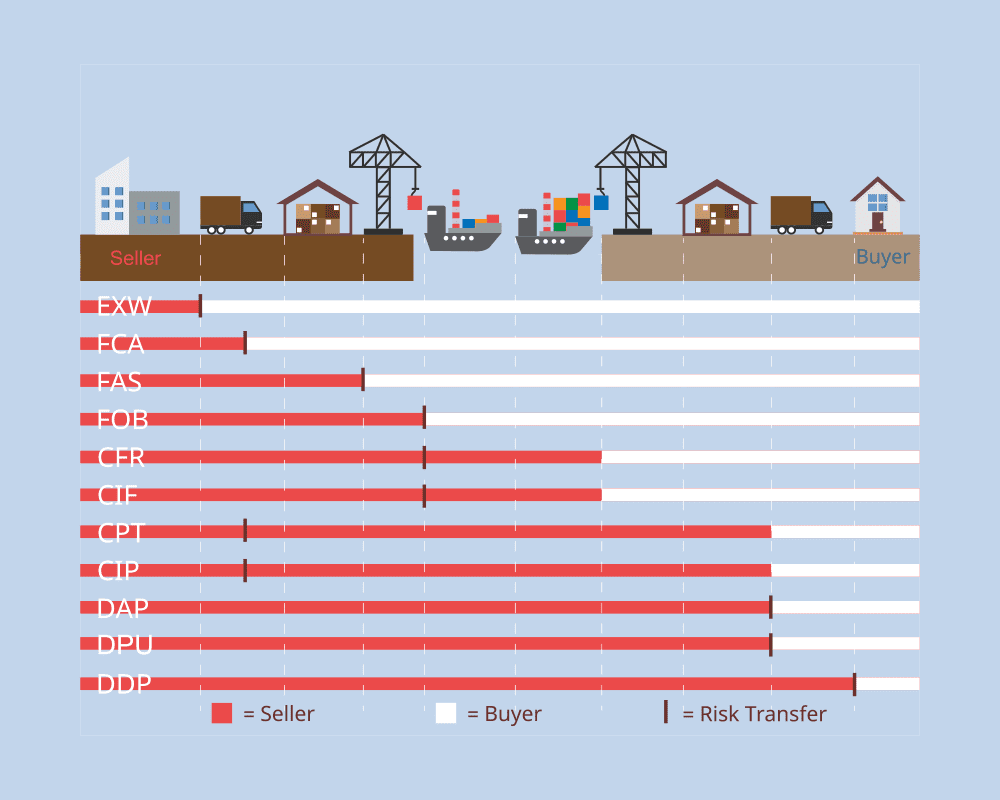

How DDP compares to other Incoterms:

- FOB: Buyer handles ocean freight and all import procedures

- CIF: Seller covers ocean freight, but buyer still handles customs

- DDU: Seller delivers goods but duties/taxes are paid by the buyer

- DDP: Seller covers everything until final delivery

In construction, where deadlines, labor schedules, and budget accuracy carry enormous weight, DDP directly resolves the most common pain points.

Key Advantages of DDP for Construction Procurement

Predictable, All-Inclusive Costs

One of the biggest frustrations in international sourcing is the uncertainty of final landed costs. With DDP, all expenses are bundled:

- Ocean freight

- Import duties

- Customs brokerage

- Port handling charges

- ISF filing

- Trucking to warehouse or job site

This gives procurement teams a single fixed number—eliminating surprise invoices and making project budgeting far more reliable.

No Need to Handle Customs or Paperwork

Importing materials requires numerous documents, filings, and compliance steps:

- Commercial invoice

- Packing list

- Bill of lading

- ISF

- Certificate of origin

- HS code classification

- Duty payment

- Customs clearance forms

Under DDP, the seller manages all of this.

For busy construction teams, this eliminates:

- Hours of administrative work

- Miscommunication with brokers

- Risk of incorrect filings

- Delays caused by compliance errors

DDP removes the most complicated part of international procurement.

Faster Material Availability & More Reliable Timelines

Any delay in material arrival can disrupt labor schedules, subcontractor planning, and critical project timelines. DDP ensures:

- Direct delivery to the project address

- No waiting for customs clearance

- No need for buyer coordination at the port

- No unexpected storage fees or demurrage

Materials move through the logistics chain faster and with fewer interruptions—helping maintain project continuity.

Reduced Operational & Compliance Risks

International procurement exposes buyers to numerous risks:

- Port congestion

- Customs inspections

- Incorrect documentation

- Duty miscalculations

- Unexpected fees

- Lost or delayed containers

Under DDP, these risks are transferred to the seller, who manages logistics through professional freight partners and local brokers. For construction companies juggling multiple projects, this reduction in operational complexity is a major strategic advantage.

Easier Multi-SKU Procurement for Complex Projects

Construction sourcing often involves:

- Several material categories

- Dozens of SKUs

- Mixed packaging

- Small-batch replenishment

- Deliveries to multiple job sites

DDP simplifies this by providing door-to-door delivery without requiring separate coordination for each SKU or shipment. This makes global sourcing of cabinets, doors, moldings, hardware, and accessories much easier.

How DDP Works: A Step-by-Step Guide

Step 1: Seller arranges production and export documentation

Commercial invoice, packing list, certificate of origin, customs export filing.

Step 2: Seller books ocean freight and handles ISF

Buyer is not involved in port operations.

Step 3: Seller’s customs broker completes import clearance

Including duty payment and HS code classification.

Step 4: Seller prepays duties and all relevant fees

Ensures smooth clearance with no surprises.

Step 5: Final delivery to buyer’s warehouse or job site

Local trucking arranged by seller; buyer simply receives the shipment.

From the buyer’s perspective, the process is essentially: “Place the order, wait for delivery.”

When Choosing DDP Makes the Most Sense

DDP is ideal when:

- Import experience is limited

- Multiple projects require consistent timelines

- Teams lack dedicated customs or logistics staff

- Orders include numerous SKUs

- Budget certainty is a priority

- Projects cannot risk delays or compliance issues

DDP may not be necessary when:

- The buyer has a mature logistics team

- Annual import volumes are extremely large

- The company prefers to negotiate its own freight contracts

Real-World Example: How DDP Saved a U.S. Project

A U.S. construction firm previously sourced interior doors from Brazil. When tariffs increased, their costs surged and shipments became unpredictable. Upon switching to an Asian supplier offering DDP:

- The supplier handled all customs clearance

- Delivery arrived directly at the project site

- No additional brokerage or duty payments were required

- Lead times became shorter and more stable

- Total landed cost decreased significantly

This shift enabled the buyer to scale from trial orders to over 100 containers annually—without increasing their procurement workload.

Final Takeaways: Why DDP Is Becoming the Preferred Model in 2025

- Global procurement is accelerating, but complexity remains a major barrier.

- DDP provides a simplified, predictable, and low-risk pathway for international sourcing.

- For construction projects with strict timelines and budget requirements, DDP makes global procurement feel as easy as local purchasing.

By removing logistics challenges and providing true door-to-door delivery, DDP helps construction teams focus on what matters most—project execution, quality control, and timely delivery.