Introduction

Imagine you’re walking through a jobsite where drywall is up, painting is scheduled, and finishing carpentry is the final step before turnover. The corners of every room—hallways, kitchens, stairwells, and trims—need clean, durable finishing. At this stage, choosing the right corner moulding becomes more than a detail; it directly affects the project’s durability, appearance, and rework rate.

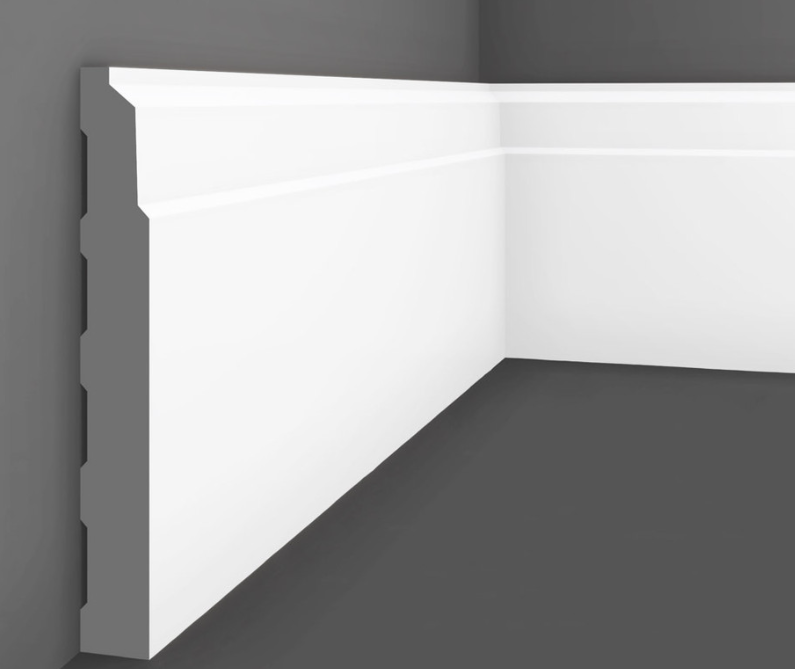

Outside corner moulding is designed to protect and finish exposed convex corners, giving them impact resistance and a crisp profile; inside corner moulding, on the other hand, is used for concave joints, where it helps cover gaps, movement, or uneven surfaces between two walls or trims. In terms of installation, outside corners require precise alignment and strong fastening to handle impacts, while inside corners emphasize tight fits, caulking, and clean transitions. These functional differences shape how each type is selected and installed on a professional jobsite.

What Are Corner Mouldings and Why They Matter in Construction

Corner mouldings are trim components designed to finish, reinforce, and visually enhance the intersections where surfaces meet. In residential and commercial construction, they help solve three common site challenges: exposed edges, inconsistent drywall work, and movement between adjoining surfaces.

For builders, mouldings are not just aesthetic pieces—they are functional elements that contribute to long-term durability. They prevent chipping on high-traffic outside corners, hide interior wall imperfections, and allow for expansion or slight misalignment between drywall, wood panels, or cabinetry.

Common materials include MDF, hardwood, PVC, polystyrene, and metal for commercial environments. MDF and wood offer smooth paint finishes; PVC and composite alternatives provide moisture resistance; metal is chosen for high-impact areas.

Understanding these fundamental roles makes the selection of inside and outside corner mouldings more intentional and ensures the finish work meets both structural and aesthetic expectations.

Outside Corner Moulding vs Inside Corner Moulding: Functions, Applications & Key Differences

Outside Corner Moulding

Outside corner moulding protects and defines convex corners—areas prone to impact from movement, furniture, or daily use. Builders commonly install them for:

- Drywall outside corners

- Columns or boxed-in beams

- Cabinet or millwork edges

- Wainscoting or paneling ends

Its primary role is reinforcement, providing clean visual edges and added protection.

Inside Corner Moulding

Inside corner moulding fills and finishes concave corners. It is commonly used for:

- Wall paneling

- Shiplap and tongue-and-groove boards

- Cabinetry and built-ins

- Crown moulding transitions

- Baseboard corners without miter joints

Its key advantage is flexibility—excellent for hiding gaps, correcting uneven surfaces, and absorbing wall movement.

Key Differences Builders Should Note

1. Functional purpose

- Outside corners = protection and visual emphasis

- Inside corners = gap coverage and smooth transitions

2. Installation complexity

- Outside corners require precise alignment and firm fastening

- Inside corners are more forgiving and conceal irregularities

3. Durability

- Outside corners endure more physical impact

- Inside corners prioritize clean finishing over impact resistance

4. Visual effect

- Outside corners create crisp defined lines

- Inside corners create soft, blended transitions

Installation Tips & Best Practices for Both Corner Types

Outside Corner Moulding Installation Tips

- Pre-measure and dry-fit to catch wall irregularities early.

- Use adhesive + brad nails for maximum durability.

- Ensure both sides sit flush—even slight misalignment shows.

- Caulk and sand before painting for a seamless finish.

Inside Corner Moulding Installation Tips

- Accommodate slight angle variations in the walls.

- Nail into studs whenever possible for better long-term stability.

- Apply a thin bead of caulk for smooth visual transitions.

- Cut carefully to avoid visible gaps that caulk can’t hide.

Common Mistakes to Avoid

- Over-nailing outside corners

- Leaving inside corner gaps uncaulked

- Using non-moisture-resistant materials in wet areas

- Ignoring uneven drywall before installation

- Painting before caulk cures

Conclusion

Corner mouldings are essential details that impact durability, finish quality, and long-term performance. Outside corner moulding strengthens and sharpens exposed edges, while inside corner moulding creates smooth transitions and covers imperfections. By understanding their functions and applying correct installation techniques, builders can deliver cleaner finishes, reduce rework, and improve the overall quality of every project.