Have you ever wondered why some homes feel more structurally balanced, quieter, or simply better built—even when their materials appear similar on the surface? When planning a renovation or adding long-span structural beams, many homeowners assume steel or concrete must be the strongest options. But modern engineered wood—especially LVL (Laminated Veneer Lumber)—has changed the game. LVL offers an exceptional combination of high strength, lighter weight, faster installation, and lower cost, making it one of the top choices for residential beams today. So what makes LVL outperform steel and concrete in home construction? Let’s take a closer look.

LVL, or Laminated Veneer Lumber, offers an exceptional strength-to-weight ratio, outstanding dimensional stability, and easier installation compared to traditional structural materials. Unlike steel beams that require heavy machinery or concrete beams that add significant weight and curing time, LVL provides reliable long-span performance, faster project timelines, and lower overall costs. Learn how engineered wood beams can enhance structural efficiency, support open-concept home designs, improve sustainability, and deliver long-term value for modern residential building.

What Is LVL and Why Builders Prefer It

Laminated Veneer Lumber (LVL) is created by bonding multiple layers of thin wood veneers under heat and pressure. This results in a remarkably strong, uniform, and dimensionally stable material ideal for structural applications.

Common uses for LVL beams include:

- Floor beams

- Roof beams

- Door and window headers

- Long-span openings

- Load-bearing walls

Because LVL is engineered for consistency, it eliminates many of the natural weaknesses found in solid wood while offering easier handling compared to steel and concrete.

Exceptional Strength-to-Weight Ratio

When comparing LVL vs steel beams, one of LVL’s greatest advantages is its strength relative to weight.

Why LVL beams excel:

- Similar load-bearing performance to steel in many residential applications

- Lightweight enough for manual installation

- No cranes, welding, or heavy machinery required

- Ideal for long-span residential beams in open-concept homes

For remodels and additions where maneuverability matters, LVL is a clear winner.

Faster and Easier Installation

Steel requires specialized cutting, welding, and machinery. Concrete requires formwork and curing. LVL, on the other hand, is designed for simplicity.

Installation benefits:

- Cuts easily with standard carpentry tools

- Can be handled by two workers

- Perfect for indoor renovation or tight job sites

- No curing or welding delays

- Shorter overall project timelines

This makes LVL the most convenient and labor-friendly structural beam material.

Superior Dimensional Stability

One major advantage of engineered wood beams like LVL is their ability to stay straight and consistent over time. Unlike steel—which expands with heat—or concrete—which can crack—LVL maintains its shape.

Stability advantages:

- Minimal warping, twisting, or shrinking

- Excellent performance over long spans

- Predictable load-bearing behavior

- Ideal for modern open-concept structures

LVL beams provide reliable long-term structural performance essential for residential construction.

Cost Savings: Material and Labor

When comparing LVL vs steel vs concrete, LVL almost always offers better cost efficiency.

Cost-saving advantages:

- Lower material cost than steel

- No heavy equipment needed

- Reduced labor hours

- Faster installation and fewer subcontractors

For homeowners and builders managing budgets, LVL is one of the most economical beam solutions.

Eco-Friendly Construction Material

Sustainability is more important than ever, and LVL stands out as one of the most environmentally friendly structural beam options.

Environmental benefits of LVL beams:

- Made from renewable, fast-growing timber

- High yield from each log

- Lower energy consumption than steel or concrete manufacturing

- Wood naturally stores carbon

This makes LVL a preferred choice for green building initiatives.

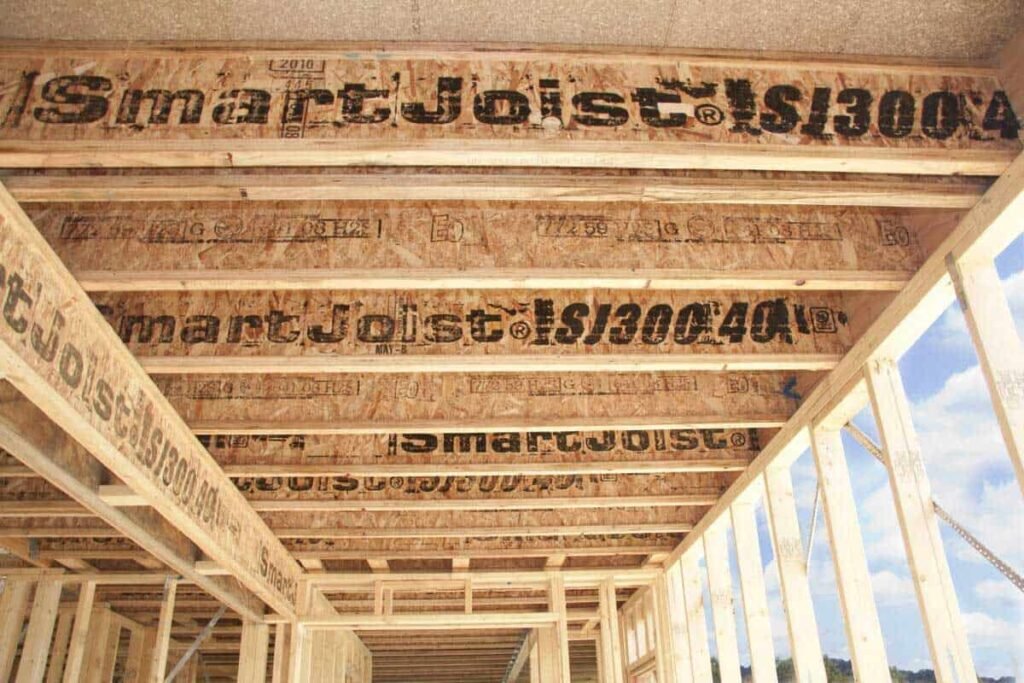

Versatility Across Residential Applications

LVL beams can be used throughout a home’s structural framework, making them one of the most versatile options available.

Applications include:

- Load-bearing beams

- Floor joists

- Roof rafters

- Garage beams

- Window and door headers

- Long-span structural supports

Because LVL beams can be produced in long, consistent lengths, they are ideal for open-concept home designs that require wide, uninterrupted spaces.

Fewer On-Site Complications

Steel beams require precise fabrication. Concrete needs time to cure. Both materials can cause schedule delays. LVL avoids these problems entirely.

LVL simplifies construction:

- Easy on-site trimming and adjustments

- Minimal weather-related delays

- No curing or welding required

- Faster project completion

This makes LVL ideal for both new construction and home renovation projects.

Conclusion: Why LVL Is the Smarter Choice for Residential Beams

When comparing LVL vs steel vs concrete, LVL consistently offers the best combination of:

- High strength-to-weight performance

- Long-term dimensional stability

- Cost efficiency

- Ease of installation

- Environmental benefits

- Versatility across residential applications

For modern home construction, LVL beams are not just an alternative—they are the superior solution. Whether you’re building a new home or opening up an existing space, LVL provides efficient, reliable, and sustainable structural support that steel and concrete simply can’t match for residential use.