In today’s fast-paced and noisy world, acoustic comfort is no longer a luxury—it’s a necessity. Whether you’re working on residential renovations, new home builds, office partitions, or studio setups, one thing is always true: a poorly soundproofed door undermines the entire effort. Sound travels through gaps, air, and materials—and unfortunately, standard doors are rarely built to block it.

The top 5 ways to enhance door soundproofing include: (1) Installing a door sweep to block noise from passing underneath the door, (2) Sealing doorframe edges with high-density weatherstripping to eliminate perimeter gaps, (3) Adding mass by applying Mass Loaded Vinyl (MLV) or acoustic panels to the door surface, (4) Using professional-grade acoustic seals around the entire door frame, and (5) Replacing lightweight hollow-core doors with solid-core models for superior sound blocking.

This guide explores the top 5 most effective ways to soundproof a door, tailored for builders, contractors, and even DIY professionals. Each method is practical, scalable, and adaptable depending on the level of sound control required. Let’s dive deeper into how each of these methods works, when to use them, and how they can be combined for maximum noise reduction in any space.

Install a Door Sweep

Why It Matters

The bottom gap of most doors is the single biggest leak point for sound. Even a 1/4 inch gap can reduce your door’s overall STC (Sound Transmission Class) rating by up to 8–10 points.

Real-World Application:

In a recent home office upgrade, replacing the base draft stopper with an automatic door sweep alone reduced outside hallway noise by nearly 40%. For professional environments like recording studios or legal offices, this is essential.

Recommended Sweep Types:

| Type | Best For | Soundproof Rating |

|---|---|---|

| Brush Sweep | Uneven floors, carpeted areas | Low |

| Silicone Blade Sweep | Hard surfaces (tile/wood) | Moderate |

| Automatic Drop Seal | High-performance areas (offices, studios) | High |

Installation Tips:

- Use a level to ensure proper sweep-to-floor contact.

- Combine with a threshold seal for maximum efficiency.

Pro Tip: When working with pre-hung doors, consider sweeps with adjustable heights to accommodate uneven flooring transitions.

Use Weatherstripping to Seal Gaps

Why It Works

Airborne noise passes through the frame gaps even if the door itself is solid. Weatherstripping closes these gaps, reducing both noise and airflow.

Common Materials:

- EPDM rubber: Resilient and durable

- Silicone compression seals: Long-lasting, used in commercial settings

- Foam tape: Budget option for short-term or DIY projects

Installation Advice:

- Measure all sides of the frame.

- Clean surfaces thoroughly—use rubbing alcohol for best adhesive performance.

- Apply weatherstripping without stretching, and avoid gaps in the corners.

Common Mistake:

Don’t double-layer weatherstripping. It may prevent the door from latching properly and degrade acoustic performance by introducing pressure points.

Add Mass-Loaded Vinyl (MLV) or Acoustic Panels

What Is MLV?

Mass Loaded Vinyl is a dense, limp material designed specifically to block sound without adding significant thickness. It works by increasing the mass of a surface, making it harder for sound waves to vibrate and pass through.

Benefits:

- Improves STC ratings by up to 10 points

- Flame retardant and safe for residential use

- Easy to apply to both new and existing doors

MLV Installation Steps:

- Measure door dimensions.

- Cut MLV to fit door slab—leave space for handle.

- Adhere using contact cement or acoustic sealant.

- Cover with fabric, panel, or decorative layer if aesthetics matter.

Acoustic Panel Options:

| Panel Type | Absorption Rating | Visual Appeal | Best Use |

|---|---|---|---|

| Foam Tiles | High (high freq) | Moderate | Studios, Home Offices |

| Fabric-Wrapped Panels | Medium | High | Conference Rooms |

| Composite Barrier Panels | High (all freq) | Low | Behind-closed door layering |

Builder Note: Combine MLV and acoustic panels for both blocking and absorbing noise, especially for shared-wall apartments or adjacent office spaces.

Apply Acoustic Door Seals

Why Acoustic Seals Matter

Even the best solid door won’t work if the perimeter leaks sound. Professional-grade acoustic door seals provide a continuous seal around the frame and threshold.

Where to Install:

- Header (top)

- Hinge side

- Latch side

- Threshold

Components of a Professional Acoustic Kit:

- Perimeter compression seals

- Automatic door bottom

- Threshold seal or sill ramp

- Strike plate gasket

Installation Order:

- Install seals on hinge and latch sides first.

- Add header seal, ensuring even compression.

- Fit automatic bottom last, adjusting drop rate for tight contact.

Warning: Poor installation (like uneven pressure or corner gaps) can completely nullify the effectiveness of the seal.

Replace with a Solid-Core Door

Why Material Matters

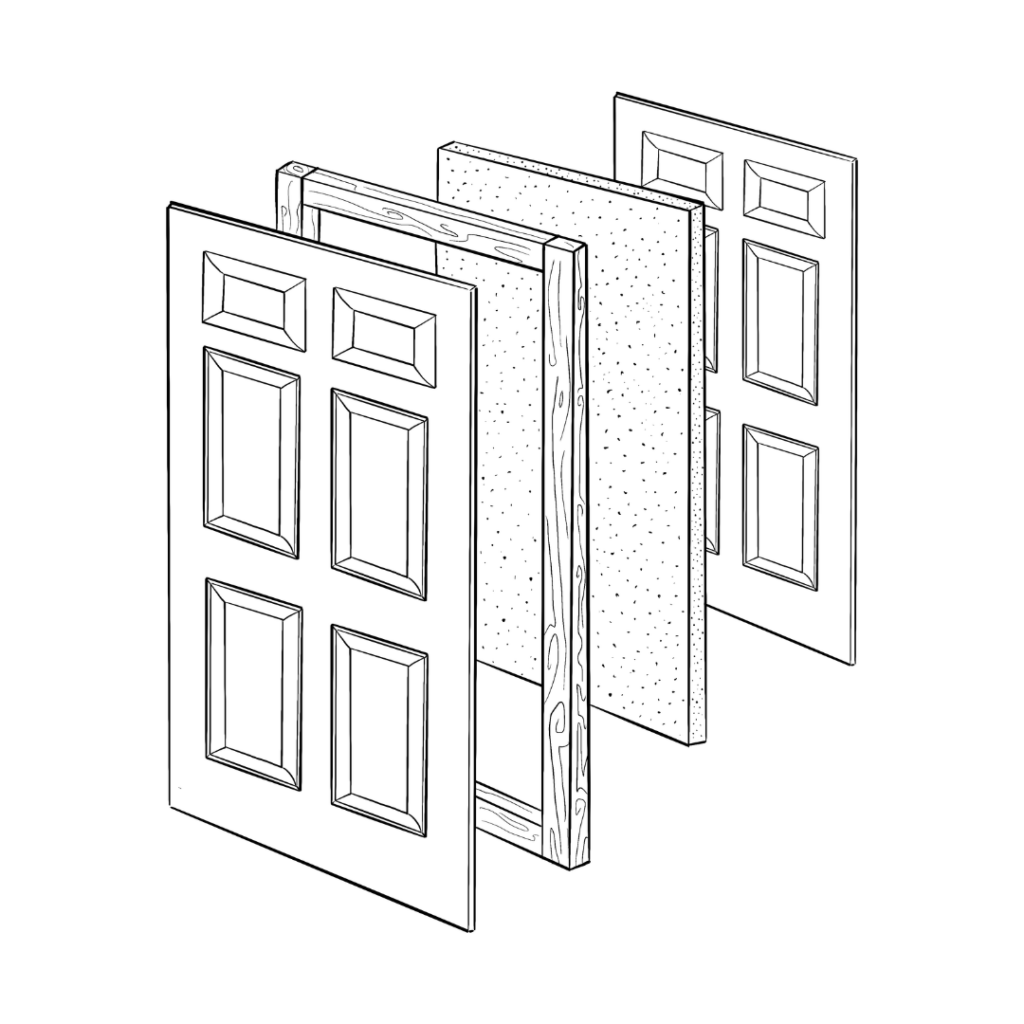

Hollow-core doors are nothing more than cardboard with a wood veneer. They offer minimal resistance to sound, especially low-frequency vibrations.

In contrast, solid-core doors (wood, MDF, or composite) offer mass and rigidity—two key characteristics of good sound blockers.

Performance by Door Type:

| Door Type | Thickness | Approx. STC | Notes |

|---|---|---|---|

| Hollow-Core (interior) | 1 3/8″ | 20–25 | Poor sound control |

| Solid-Core Composite | 1 3/4″ | 32–38 | Balanced cost and performance |

| Acoustic Rated Doors | 2+” | 40–55+ | Ideal for studios/offices |

Fire + Sound Options:

Many solid-core doors also meet fire-rating requirements, making them a great two-in-one solution for commercial buildings.

Professional Advice for Builders

Before Installation:

- Analyze the space: What kind of noise is the client concerned about? Footsteps? Voices? Music?

- Set clear expectations: Soundproofing improves isolation but doesn’t guarantee 100% silence.

- Identify flanking paths: Walls, vents, floor gaps can transmit sound even if the door is sealed.

Budget Tiers for Soundproofing:

| Tier | Estimated Cost | Components Included | STC Improvement |

|---|---|---|---|

| Basic | $20–$50 | Weatherstripping, foam sweep | +5–10 |

| Mid-Level | $80–$200 | Rubber sweep, MLV, compression seals | +10–20 |

| High-End | $300–$800+ | Solid-core door, pro acoustic seals, full kit | +20–35 |

Tip for Builders: Offer these as tiered packages to clients—let them choose based on need and budget.

Frequently Asked Questions about Door Soundproofing

Q: Can I effectively soundproof a hollow core door?

A: Honestly, no. Hollow core doors lack the physical mass required to block sound waves. While you can add weatherstripping to seal the gaps, the door panel itself will still vibrate and transmit noise (like a drum). The only effective solution is to replace it with a Solid Core or Solid Wood door.

Q: Why can I still hear noise through my solid wood door?

A: Sound flows like water—it will find the path of least resistance. If you have a solid door but can still hear noise, the issue is likely air gaps. You must seal the perimeter with acoustic gaskets and install a door sweep or threshold to block the gap at the bottom of the door.

Q: What is an STC rating?

A: STC stands for Sound Transmission Class. It is a numerical rating of how well a building partition attenuates airborne sound. A standard hollow door has an STC of ~20 (you can hear speech through it). A good solid core door has an STC of ~30-35. For true soundproofing (like a music studio), you need a specialized acoustic door with an STC of 45+.

Q: Do door sweeps damage hardwood floors?

A: Cheap rubber sweeps can cause drag marks over time. For high-end homes, we recommend installing an Automatic Door Bottom (ADB). This mechanism is mortised into the bottom of the door and only drops a seal down when the door is fully closed, protecting your floors and providing a perfect seal.

Summary

Door soundproofing is one of the most cost-effective ways to enhance comfort, privacy, and acoustic quality in any space. Whether you’re building a quiet home office, a recording room, or trying to improve apartment sound control, these five methods deliver serious results: Install a high-quality door sweep, apply durable, well-fitted weatherstripping , add density with MLV and/or acoustic panels, use complete perimeter acoustic sealing kits and replace hollow doors with solid-core alternatives. With the right materials, tools, and knowledge, builders can dramatically improve sound control—delivering both peace of mind and professional satisfaction.

Articles that you may be interested in:

What We Learned from Supplying Doors for 50+ Construction Projects