Tight budget but demanding clients? Choosing the wrong interior doors can lead to overspending and rework. The good news is that molded doors offer a cost-effective solution—ideal for high-volume renovation and construction projects.

Molded doors are affordable interior doors made from MDF skins and filled with a honeycomb paper core. They mimic the look of real wood panels but cost significantly less. These doors are lightweight, easy to install, and ideal for budget-conscious contractors working on volume-based projects like rentals, offices, or residential renovations.

Let’s break down what molded doors are made of, how they perform, and how to choose the best options without compromising style or quality.

What are molded doors made of?

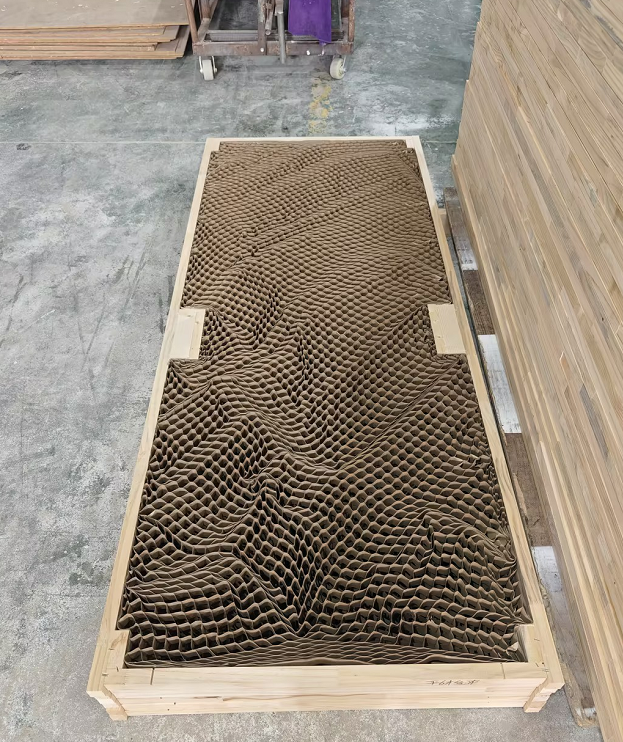

Molded doors are typically made using medium-density fiberboard (MDF) skins that are pressed into decorative shapes. The inside of the door is filled with a honeycomb paper core, which keeps the door lightweight while still providing structural stability.

MDF is an engineered wood product known for its smooth surface and affordability. The honeycomb paper core gives the door strength without the weight or cost of solid wood. This makes molded doors an excellent choice for fast-paced construction environments.

Are molded doors cheaper than wood doors?

Yes—molded doors are significantly more affordable than solid wood doors. While a traditional wood interior door might cost several hundred dollars, a molded composite door typically ranges from $60 to $150, depending on size, style, and finish.

In addition, molded doors are much lighter, which reduces shipping and installation costs. That’s a major advantage for contractors managing large-scale projects where every dollar counts.

Are molded doors durable enough for contractors?

For most interior applications, yes. Molded doors are durable enough to handle everyday wear and tear in residential and commercial settings, especially when they are solid or semi-solid core models.

That said, they’re not designed for high-moisture or high-impact environments like bathrooms or public lobbies. For those spaces, it’s better to upgrade to a solid wood or water-resistant alternative.

Still, for bedrooms, hallways, offices, and apartment units, molded doors are a proven, reliable solution.

What’s the difference between molded and flush doors?

The main difference is design:

- Flush doors are flat with no detailing—ideal for minimalist interiors.

- Molded doors are made by compressing MDF into decorative, raised-panel shapes that imitate the look of traditional wood doors.

Both types are relatively inexpensive, but molded doors often give clients a more “premium” look for less money, making them an attractive upgrade in budget-conscious builds.

When sourcing, look for:

- MDF molded skins

- Honeycomb core

- Pre-primed finishes

- Pre-drilled holes for hinges and locks

These features save time on-site and reduce labor costs.

Why are MDF molded doors with honeycomb core ideal for volume projects?

As a contractor, you need materials that are consistent, affordable, and easy to work with. Molded doors check every box:

- Lightweight: Easy to transport and install

- Standardized: Uniform design simplifies bulk orders

- Cost-efficient: Low material and shipping cost

- Low maintenance: Easy to repair or replace if damaged

Whether you’re outfitting a rental property, a new office build, or a residential remodel, molded doors help you stay on budget without sacrificing style or function.

Frequently Asked Questions about Molded Doors for Contractors

Q: What is the difference between “Hollow Core” and “Solid Core” molded doors?

A: Both use the same molded fiberboard skins (facings). The difference is the inside: Hollow core uses a cardboard honeycomb structure (lightweight, low soundproofing), while Solid Core is filled with particleboard or mineral composite. For rentals and master bedrooms, we strongly recommend Solid Core to prevent damage and reduce noise complaints.

Q: How much can I trim off a molded door?

A: Very little. Unlike solid wood doors, molded doors have a thin internal frame (stile and rail). typically, you can only trim up to 1 inch from the bottom. Cutting more than that will remove the structural block, causing the door skin to delaminate or the door to lose rigidity. Always check the manufacturer’s spec sheet before cutting.

Q: Smooth vs. Textured finish: Which is better for resale?

A: In 2026, the trend is heavily favoring the Smooth Finish. While the “faux wood grain” texture was popular in the 90s and 00s, modern buyers prefer the clean, painted look of smooth molded doors (like the 2-panel “Carrara” or “Cheyenne” styles) as they look more like high-end custom millwork.

Q: Do molded doors need to be primed?

A: Most quality molded doors come factory-primed. However, “Builder Grade” primer is often thin and rough. For a professional finish, we recommend a light sand followed by a high-quality semi-gloss topcoat. Upgrading to a brand that offers “double-coat” priming can save your painters significant prep time.

Summary

Molded doors are a smart, stylish, and affordable solution for contractors looking to save on interior materials. Lightweight yet durable, easy to install, and available in a range of designs, they’re the go-to choice for high-volume construction projects.

Articles that you may be interested in:

What Is a Shaker Style Molded Door? How It Differs from a Traditional Shaker Door

Finishing Options for Molded Doors: Primed, Paint, Laminate, and Wood Veneer

Builder’s Guide to Sourcing Molded Doors: Key Factors to Consider