Picture this: your crew is on site, cabinets are set, and the schedule is tight. The wholesaler drops off a pallet of “standard” replacement doors—only to find the hinge-bore pattern doesn’t line up, the overlay is wrong by 3/16″, and two pantry fronts are a shade short because the boxes are full-overlay frameless, not face-frame. Now the painter is idle, the punch list grows, and everyone is asking the same question: if kitchen cabinet doors are supposed to be standard, why doesn’t “standard” fit?

Kitchen cabinet doors do follow industry-standard ranges, but they are not universal. Base cabinet doors typically measure 9″–36″ wide and 24″–30″ high, wall cabinet doors 9″–36″ wide and 12″–42″ high, and tall/pantry doors 84″–96″ high and 18″–30″ wide, with drawer fronts 12″–36″ wide and 5″–12″ high. Builders and wholesalers can rely on these common dimensions, but true sizing depends on factors such as regional systems, construction type, overlay style, and material thickness.

In this article, we’ll break down those standards, explore the variations, and offer practical guidance for both wholesalers and builders to measure, order, and stock cabinet doors with confidence.

Why Standard Kitchen Cabinet Door Sizes Matter

In the cabinet industry, size consistency is more than a technical detail—it’s the backbone of efficiency. Builders depend on predictable dimensions to plan layouts, coordinate subcontractors, and keep projects moving without interruption. A mismatched door size can throw off an entire kitchen installation, requiring costly rework or custom adjustments on site. For wholesalers, the impact is just as significant: managing large inventories becomes practical only when most cabinet doors follow repeatable size modules.

Standardization also reduces communication errors between suppliers and buyers. When both parties share a common language of “standard base width” or “36-inch wall cabinet,” the chances of ordering mistakes decrease dramatically. This is especially important for wholesalers who supply multiple builders at once—stocking a reliable range of sizes ensures they can respond quickly to varied orders without holding excessive custom stock.

From a financial standpoint, standardized cabinet door sizes help optimize manufacturing and logistics. Factories can streamline production lines, reduce material waste, and improve lead times. Distributors can consolidate shipments, minimize warehouse clutter, and plan procurement cycles more accurately. On the jobsite, builders save labor hours when installers don’t have to trim, modify, or wait for replacements.

Of course, it’s important to recognize that “standard” doesn’t mean identical across every project. Variables such as framed versus frameless construction, overlay style, and regional preferences still influence final dimensions. But within these frameworks, standard sizing provides a solid baseline that wholesalers and builders can rely on. This shared baseline is what allows large-scale projects to stay on budget and on schedule while maintaining consistent quality.

Consistency in sizing affects every step of a project:

- Builders rely on predictable modules for layout, installation, and workflow.

- Wholesalers need repeatable SKUs for stocking and fast fulfillment.

- Factories improve productivity, minimize waste, and speed lead times.

- Installers avoid costly trimming, reboring, or replacement delays.

A mis-sized door isn’t just an inconvenience—it’s a direct impact on:

- Labor cost

- Schedule certainty

- Project profitability

Complete Guide to Standard Kitchen Cabinet Door Dimensions

When people talk about “standard sizes” in kitchen cabinets, they usually mean the industry’s most common modules for base, wall, tall, and drawer fronts. These dimensions are designed to align with cabinet box sizes, appliances, and ergonomic considerations, making installation and replacement more efficient for both builders and wholesalers.

Base Cabinet Doors

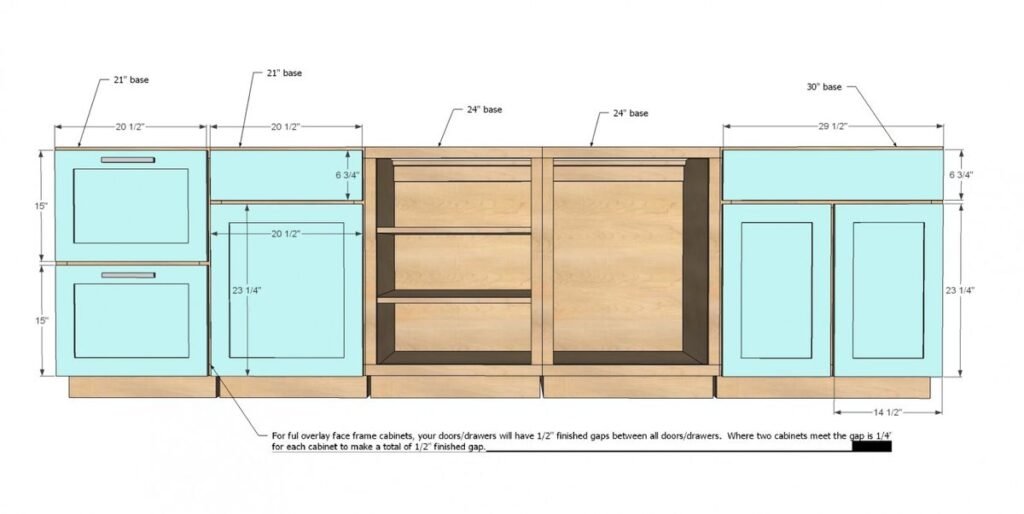

- Widths: Typically available in increments of 3 inches, starting from 9″ up to 36″ (9″, 12″, 15″, 18″, 21″, 24″, 30″, 33″, 36″).

- Heights: Commonly between 24″ and 30″, depending on the cabinet height.

- Cabinet Box Reference: Most base cabinets are 24″ deep and 34.5″ tall, so doors are sized to fit these proportions.

- Application: Single-door or double-door setups for under-counter storage.

Wall Cabinet Doors

- Widths: Also offered in 3-inch increments, ranging from 9″ up to 36″.

- Heights: Standard options include 12″, 15″, 18″, 24″, 30″, 36″, and 42″.

- Depth: Most wall cabinets are 12″ deep, though over-refrigerator cabinets may reach 15″–24″.

- Application: Upper storage, with taller options (36″–42″) reaching the ceiling.

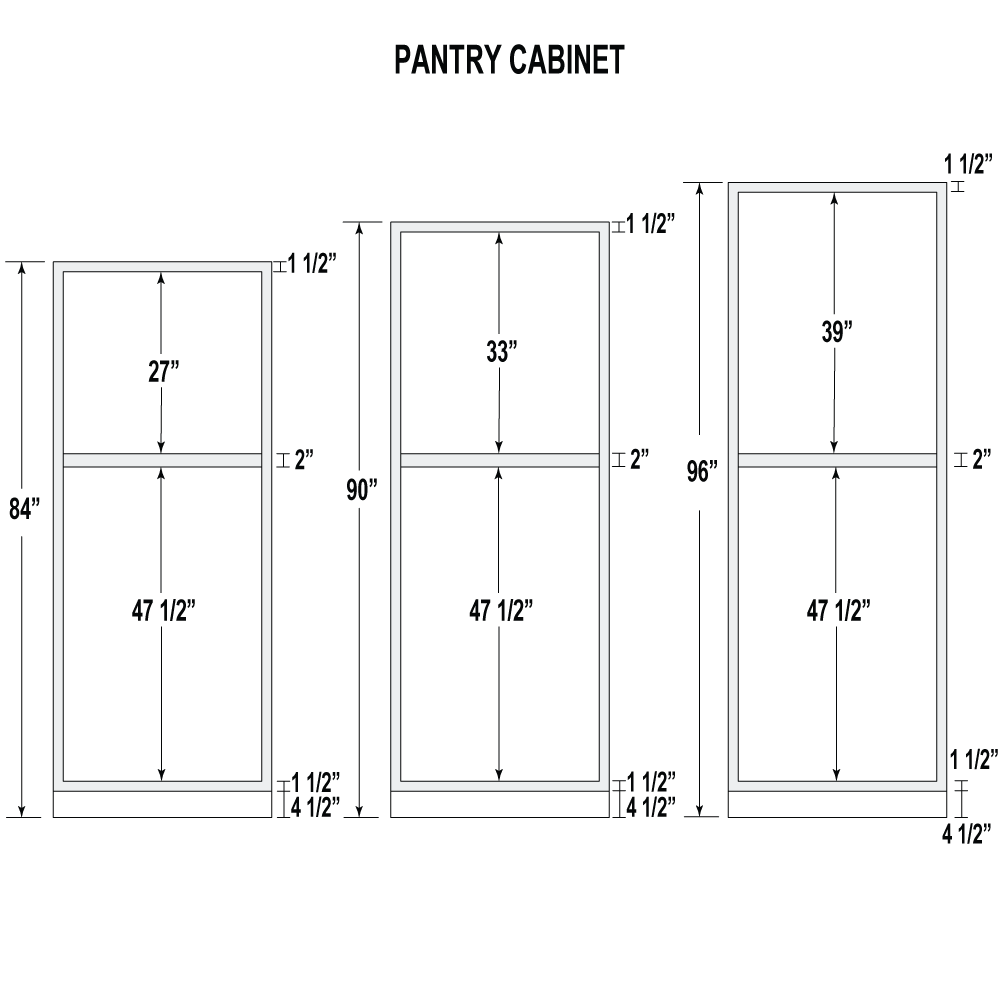

Tall Cabinet / Pantry Doors

- Heights: 84″, 90″, and 96″ are common choices, aligning with ceiling heights.

- Widths: Usually 18″, 24″, or 30″.

- Design: Tall cabinets often use double-door configurations for stability and ease of use.

- Application: Pantry storage, oven housing, or broom closets.

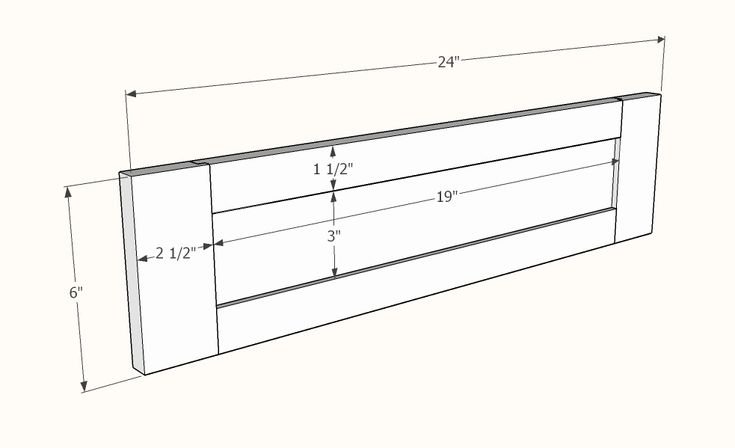

Drawer Fronts

- Widths: Match the cabinet modules (12″, 15″, 18″, 21″, 24″, 30″, 36″).

- Heights: Generally 5″–12″, depending on whether they’re used for top drawers, deep pots and pans, or utility storage.

- Application: Adds flexibility to base cabinets, allowing combinations of shallow and deep storage.

Key Takeaway

Standard Kitchen Cabinet Door Size Chart

| Cabinet Type | Width (inches) | Height (inches) | Typical Application / Notes |

|---|---|---|---|

| Base Cabinet Doors | 9, 12, 15, 18, 21, 24, 30, 33, 36 | 24–30 | Under-counter double/single doors; standard 24″ depth cabinet |

| Wall Cabinet Doors | 9–36 | 12, 15, 18, 24, 30, 36, 42 | Upper storage; 12″ typical depth; taller options reach ceilings |

| Tall / Pantry Doors | 18, 24, 30 | 84, 90, 96 | Pantry, oven cabinet, broom closet; often double-door configuration |

| Drawer Fronts | 12–36 | 5–12 | Varies by drawer depth; top drawers are shallow, base drawers deeper |

How Cabinet Style and Construction Affect Door Measurements

Even when cabinet boxes follow standard dimensions, the style and construction method of the cabinet system can significantly affect the final size of the doors. For builders, this determines how doors align and function on site; for wholesalers, it shapes how inventory must be specified and categorized.

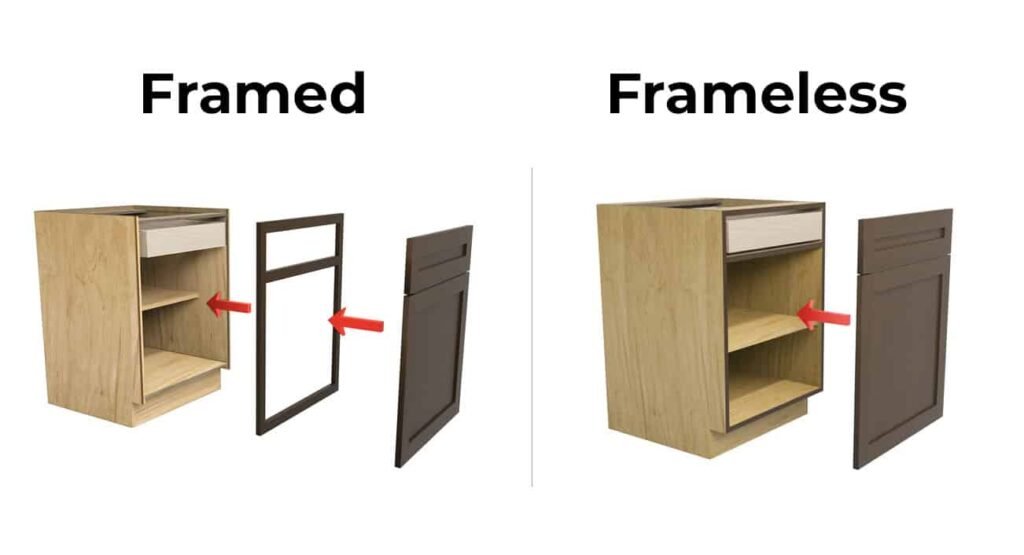

Framed vs. Frameless Cabinets

- Framed Cabinets (Traditional American style): The face frame adds structure, and doors attach directly to it. Door dimensions must account for the frame width, with options for inset, partial overlay, or full overlay.

- Frameless Cabinets (European style): Doors cover the box directly without a frame. Sizing is usually larger to provide full coverage, and hinges are mounted to the side panels instead of a frame.

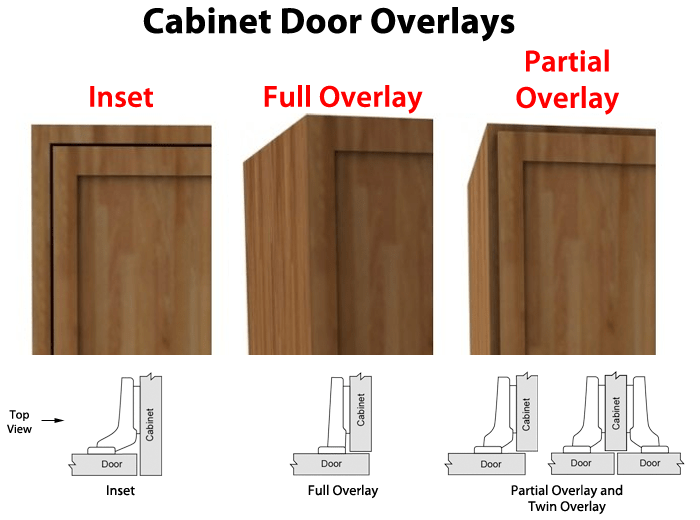

Overlay Types

- Inset Doors: Fit flush within the cabinet frame opening, requiring precision sizing. A slight gap tolerance (about 1/16″) is necessary for smooth operation.

- Partial Overlay Doors: Cover part of the face frame, leaving a visible reveal. This overlay style is forgiving but requires consistent reveal sizes across doors for a uniform look.

- Full Overlay Doors: Cover nearly the entire face frame or side panel, creating a seamless, modern appearance. These require accurate sizing and hinge placement to avoid interference between adjacent doors.

Material Considerations

- Solid Wood: Natural expansion and contraction must be considered, so sizing may include allowances for seasonal movement.

- MDF and Thermofoil: More dimensionally stable, making them popular for precise, modern door styles.

- Specialty Materials (Acrylic, Metal, Glass): May require non-standard thicknesses or edge treatments that influence door fit.

Thickness and Hardware

- Standard cabinet doors are typically 3/4″ thick, but variations exist (5/8″ or 7/8″) depending on material and style. Thickness directly impacts hinge selection, bore depth, and clearances.

Key Point

While cabinet boxes may follow standard heights and widths, the overlay choice, construction style, and material will dictate the final door size. Both wholesalers and builders must align on these factors during ordering to ensure consistent fit, function, and aesthetic results.

Builders’ Guide: Measuring and Ordering the Right Cabinet Doors

While cabinet boxes may follow standard heights and widths, the overlay choice, construction style, and material will dictate the final door size. Both wholesalers and builders must align on these factors during ordering to ensure consistent fit, function, and aesthetic results.

Even with standard sizes available, builders know that accuracy in measurement is the difference between a flawless installation and a costly delay. Ordering cabinet doors isn’t just about picking a width and height—it’s about confirming every specification that affects fit and function.

Step 1: Measure the Cabinet Opening

- Always start by measuring the inside opening of the cabinet box.

- Take width and height at multiple points to check for any inconsistencies.

- Record measurements in the correct system (inches vs. millimeters) to avoid costly conversion errors.

Step 2: Decide on Construction and Overlay

- Framed cabinets: Determine whether the door will be inset, partial overlay, or full overlay. This changes the final door dimension by fractions of an inch.

- Frameless cabinets: Doors usually cover the entire opening, but the exact overlay amount must be specified for smooth alignment.

Step 3: Confirm Door Style and Thickness

- Common thickness is 3/4″, but check if the project requires 5/8″ or 7/8″.

- For styles like shaker or raised panel, confirm whether the edge profiles affect the opening clearance.

- Glass insert or louvered doors may need additional reinforcement or hardware adjustments.

Step 4: Account for Hardware and Hinge Boring

- Verify hinge boring location, diameter, and depth—especially when reordering doors for an existing installation.

- Builders should specify the hardware brand (e.g., Blum, Hettich) to ensure compatibility.

- Don’t forget handles or pulls, as their placement can influence usability in tight spaces.

Step 5: Communicate Clearly with Suppliers

- Provide drawings, cut sheets, or CAD files whenever possible.

- Double-check part numbers for repeat orders, especially with wholesalers who stock multiple lines.

- Ask for samples or photo confirmations if ordering from a new supplier.

Key Takeaway

For builders, accuracy at the ordering stage saves hours of frustration later. By combining precise measurements with clear communication of overlay, thickness, and hardware needs, builders can ensure that the doors delivered to site are truly “ready to hang.” For wholesalers, these detailed specifications prevent returns, rework, and strained relationships with contractors.

Conclusion: Standard Kitchen Cabinet Door Sizes and Industry Best Practices

So, are kitchen cabinet doors standard size? The answer is both yes and no. Industry norms do exist—base, wall, tall, and drawer fronts follow predictable modules that wholesalers can stock and builders can trust. Yet, as we’ve seen, construction methods** (framed vs. frameless), and style choices (inset, partial, or full overlay) all influence the final measurements.

For wholesalers, understanding these conventions means stocking the right mix of standard SKUs while leaving room for flexibility with custom orders. For builders, precision in measuring openings, choosing overlays, confirming thickness, and specifying hardware is what ensures seamless installations.

Ultimately, standard sizes provide a reliable framework—but the real success comes from aligning those standards with project-specific details. By mastering both the common dimensions and the exceptions, wholesalers and builders can work together to deliver kitchens that are efficient to produce, simple to install, and built to last.