Introduction

For many builders and project managers, importing doors, mouldings, or cabinets from overseas is no longer unusual. What often causes problems is not the product itself, but the shipping terms hidden in the quotation. Two suppliers may offer similar prices, lead times, and specifications—yet one quote is based on DAP, while the other is DDP. On paper, the difference may seem minor. In practice, it can lead to unexpected duties, customs delays, storage charges, and jobsite disruptions once the container arrives.

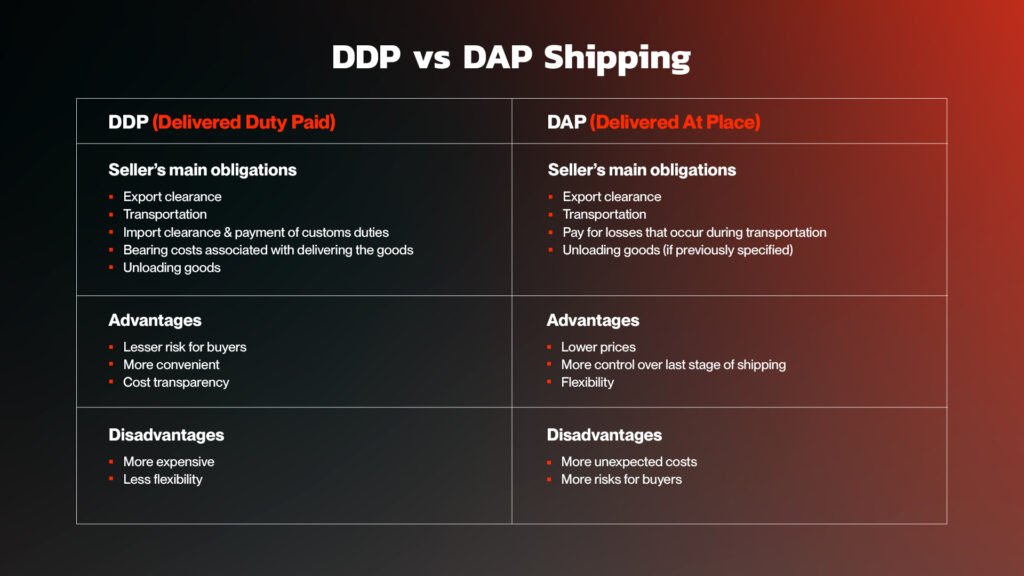

The core difference is straightforward: under DAP (Delivered At Place), the seller delivers the goods to a named location, while the buyer is responsible for customs clearance, import duties, taxes, and often final delivery; under DDP (Delivered Duty Paid), the seller assumes full responsibility for the shipment, including customs clearance, duties, taxes, and delivery to the agreed destination. For builders, this distinction directly affects total landed cost, risk exposure, and schedule control.

What Is DAP (Delivered At Place)?

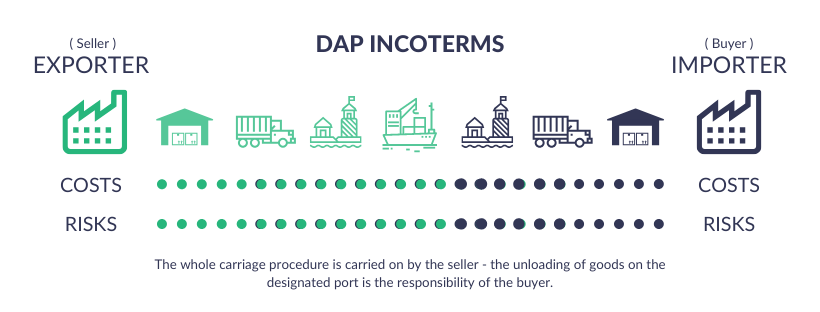

Under DAP, the supplier is responsible for manufacturing the goods and transporting them to a specified destination, such as a port or warehouse. Once the shipment arrives, responsibility transfers to the buyer. Customs clearance, import duties, inspections, and final trucking to the jobsite are handled by the builder or their appointed agents.

DAP can work well for builders with established import processes, strong broker relationships, and internal teams capable of managing clearance and delivery. In these cases, builders may prefer direct control over the import stage.

However, DAP also introduces cost and schedule uncertainty. Duties and port-related fees are not always predictable, and inspections or documentation issues can delay release. Even short port delays can trigger demurrage or storage charges. For projects tied to fixed schedules, these delays often translate into labor rescheduling and increased overall project cost.

What Is DDP (Delivered Duty Paid)?

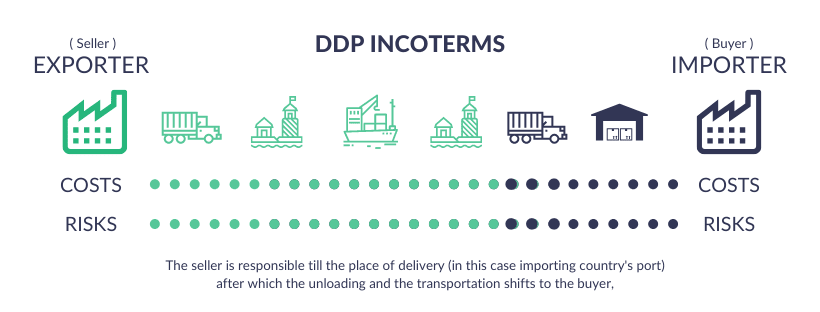

Under DDP, the seller takes responsibility for the entire shipment from origin to final destination. This includes international freight, customs clearance, import duties, taxes, and delivery to the agreed location—whether a warehouse or directly to the jobsite.

For builders, DDP simplifies procurement. Costs are consolidated into a single landed price, paperwork is handled by one party, and accountability is clearly defined. Instead of coordinating multiple service providers, the builder works with a single supplier responsible for delivery.

While DDP is often assumed to be more expensive, it frequently provides better cost predictability, especially for projects involving large volumes, multiple SKUs, or phased deliveries. The effectiveness of DDP depends less on the Incoterm itself and more on the supplier’s experience handling customs and local delivery.

DDP vs. DAP: Differences That Matter to Builders

Cost Structure

DAP pricing often appears lower because duties and clearance fees are excluded. These costs surface later, making budget control more difficult.

DDP pricing includes these elements upfront. Although the unit price may appear higher, builders gain clearer visibility into total landed cost.

Responsibility and Risk

With DAP, the builder assumes risk once the goods reach the destination point. Customs delays or documentation issues become the buyer’s responsibility.

With DDP, these risks are transferred to the seller, reducing the builder’s exposure—particularly valuable on complex or time-sensitive projects.

Project Scheduling

Most construction projects require materials in phases rather than all at once. Under DAP, shipments are often delivered in bulk, requiring the builder to manage storage and internal distribution.

DDP arrangements can support phased deliveries aligned with project milestones, helping reduce warehouse pressure and improve jobsite efficiency.

Cash Flow Impact

DAP involves multiple payments handled at different stages—freight, duties, trucking, and storage—which can complicate cash flow planning.

DDP consolidates logistics costs into a single, predictable payment, making financial planning easier for builders working within tight budgets.

Which Shipping Term Makes Sense for Builder Projects?

DAP may be suitable for large developers with in-house logistics teams and projects near major ports. These builders often prioritize direct control and have systems in place to manage import complexity.

DDP is often a better fit for most builder-driven projects, especially those involving overseas suppliers, mixed product categories, or tight timelines. When the priority is keeping the jobsite moving, DDP offers a more streamlined and predictable approach.

Common Mistakes Builders Make

A common mistake is comparing prices without comparing responsibilities. Two quotes are not equivalent if one includes duties and delivery while the other does not.

Another mistake is assuming all DDP offers are the same. DDP only works well when the supplier has real experience managing customs and final-mile delivery.

Finally, many builders address shipping terms too late in the process, after contracts are finalized, when flexibility has already been lost.

Frequently Asked Questions about DDP vs. DAP Shipping

Q: Is DDP always the best choice for first-time importers?

A: Yes. If you do not have a dedicated logistics manager or an existing relationship with a US Customs Broker, DDP is the safest option. It locks in your total cost upfront and shifts the complex liability of customs clearance, tariffs, and port fees to the supplier.

Q: Why is the DAP quote cheaper than the DDP quote?

A: DAP quotes exclude Import Duties (Tariffs) and Brokerage Fees, which can add 25% or more to the final cost of building materials (especially with Section 301 tariffs). A “cheaper” DAP quote often becomes more expensive once you receive the separate bill from the government for these taxes.

Q: Does “Delivered Duty Paid” (DDP) mean the driver will unload the doors?

A: No. This is a common misconception. DDP means the goods will be delivered to your jobsite, but it is almost always “Curbside” or “Dock” delivery. You (the builder) are responsible for having a forklift or crew ready to unload the container within the allotted free time (usually 1-2 hours) to avoid detention charges.

Q: Can I track my shipment differently with DDP vs. DAP?

A: With DDP, the seller controls the entire chain, so you rely on them for updates until the goods reach the local distribution hub. With DAP, you (or your forwarder) take control once the ship arrives, giving you more direct visibility into the customs clearance status—but also more responsibility to fix issues if they get stuck.

Conclusion

DDP and DAP are more than shipping terms—they define who controls cost certainty, risk, and delivery reliability in a construction project. While DAP can work for builders with mature import systems, many projects benefit from the predictability and accountability that DDP provides. The right choice is not about selecting the lowest price on paper, but about choosing the delivery model that best supports the project schedule and keeps the jobsite moving.

Articles that you may be interested in:

FOB vs DDP Shipping for Building Materials

FCL vs LCL: Which Shipping Option Is Better for Building Material Importers?