Most people confuse overall flooring thickness with wear layer — a mistake that can lead to poor product performance and unhappy clients. If you’re a builder or wholesaler, understanding these two specs isn’t just smart — it’s essential. Let’s break it down with clarity, strategy, and zero fluff.

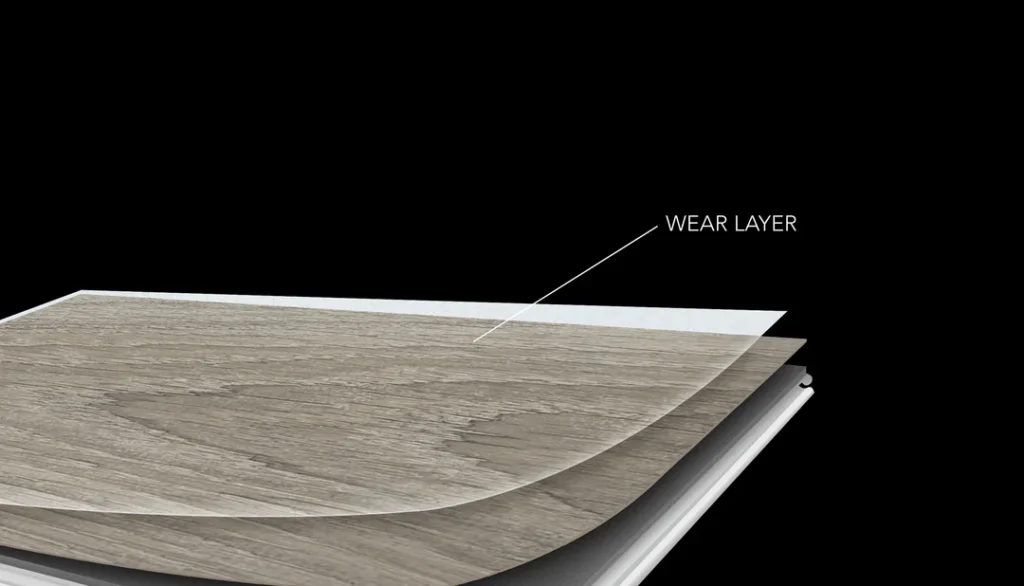

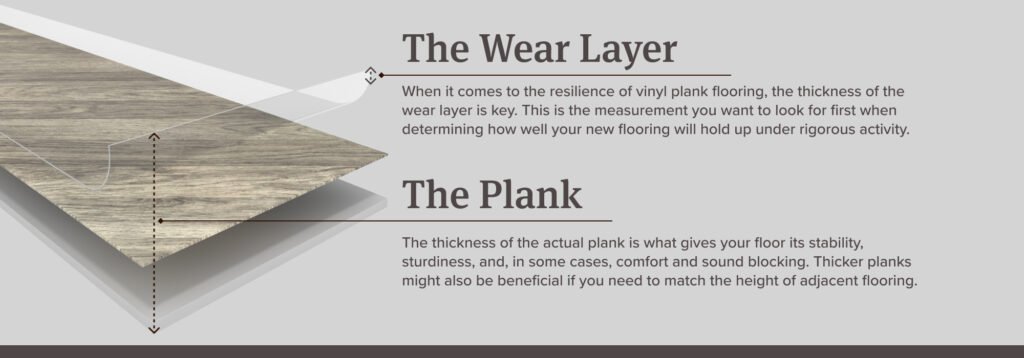

Flooring thickness refers to the total depth of the material, while the wear layer is the top protective surface that resists foot traffic, scratches, and stains. Measured in mils (thousandths of an inch), thicker wear layers (e.g., 20–28 mils) offer longer durability, especially in commercial settings. Always match the wear layer to the expected traffic.

Now that you know the basic difference, let’s dive deeper into how wear layers work, what the mil ratings really mean, and how to choose the right specs for different clients.

What does sheet flooring thickness and wear layer really mean?

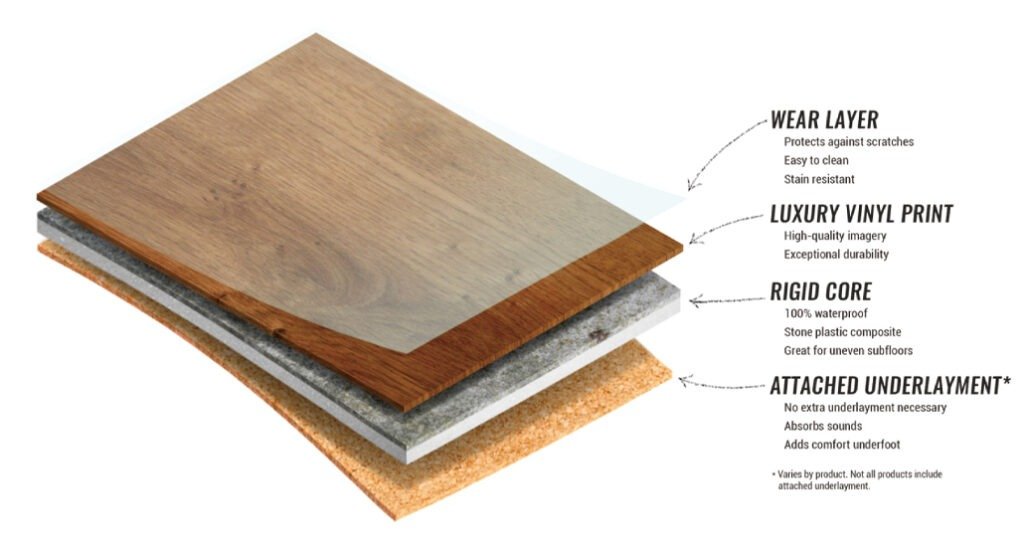

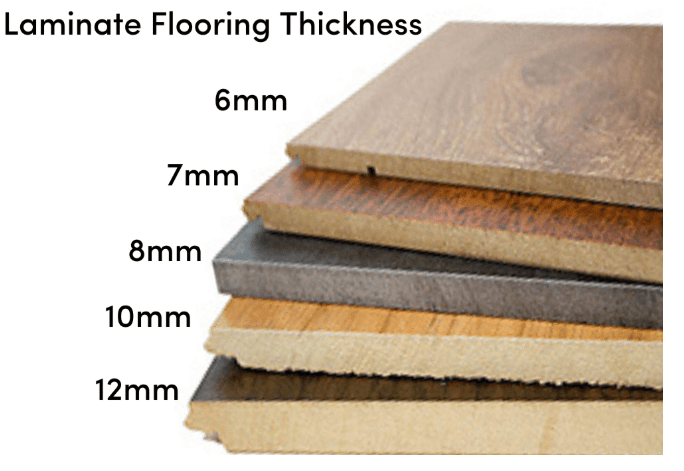

When evaluating sheet flooring, two specifications matter most: overall thickness and wear layer thickness — and they serve very different purposes. Overall thickness (typically between 2mm to 5mm) refers to the total depth of the flooring, including the backing, core layer, and surface treatment. Thicker sheet flooring tends to offer better sound absorption, thermal insulation, and comfort underfoot, which is particularly valuable in residential settings or multi-level buildings. On the other hand, the wear layer is the transparent top coating that protects the decorative layer underneath. Measured in mils (1 mil = 0.001 inch), it determines how resistant the flooring will be to foot traffic, scratches, stains, and indentations. For example, a 10–12 mil wear layer suits light residential use, while 20–30 mil is recommended for commercial and high-traffic areas. Builders and wholesalers should never assume that thicker floors automatically mean more durability — it’s the wear layer that defines long-term performance. Clients looking for durability, easy cleaning, and low maintenance should prioritize the wear layer thickness over total product thickness. When selecting sheet flooring, always match both specs to the use-case: heavier wear for rentals or kitchens, moderate for bedrooms and living areas.

What are professionals saying about wear layers?

Flooring professionals widely agree that wear layer thickness is one of the most important indicators of long-term durability. Installers and product specialists emphasize that the wear layer—not the overall plank thickness—is what truly determines how well flooring holds up against scratches, stains, and foot traffic. Many pros recommend a minimum of 20 mil for high-traffic areas or light commercial use, noting that anything less may lead to early surface damage, especially in homes with pets or rental properties. While thicker floors may offer more comfort or sound insulation, experts caution that even an 8mm thick plank can fail quickly if it has only a 6 or 8 mil wear layer. For builders and wholesalers, the consensus is clear: prioritize wear layer quality over marketing gimmicks. A well-chosen wear layer helps prevent callbacks, boosts customer satisfaction, and ensures that the flooring performs as promised for years.

What are professionals saying about flooring thickness?

Flooring professionals agree that overall thickness plays a supporting role in product performance, but it’s often misunderstood by buyers. While thicker flooring can provide better sound insulation, stability, and comfort underfoot, experts emphasize that it doesn’t automatically mean higher durability. Installers point out that the core construction and wear layer matter more when it comes to resisting wear and tear. For example, a 5mm vinyl plank with a 20 mil wear layer will often outperform an 8mm plank with only a 6 mil layer. However, in cases where uneven subfloors or acoustic performance are concerns—such as multi-level housing—thicker planks can make installation easier and reduce noise transmission. Professionals also note that thicker flooring tends to feel more solid underfoot and may better hide minor subfloor imperfections. In summary, thickness matters—but it must be evaluated alongside wear layer and product composition for a complete performance picture.

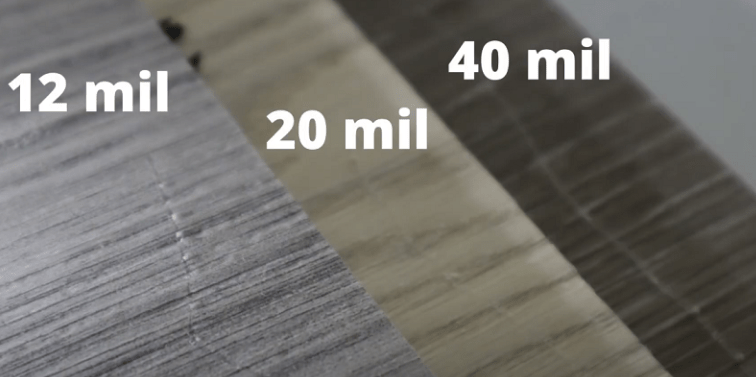

What is the difference between 12 mil and 20 mil wear layer?

The main difference between a 12 mil and a 20 mil wear layer lies in durability and intended use. A 12 mil wear layer (0.3mm) is suitable for moderate residential traffic — ideal for bedrooms, living rooms, and homes without pets or children. It offers decent protection but may show wear more quickly under heavy use. In contrast, a 20 mil wear layer (0.5mm) is designed for high-traffic areas and light commercial spaces like offices, rental units, or busy family homes. It provides stronger resistance to scratches, dents, and stains, making it a better long-term investment. For builders and wholesalers, it’s crucial to match wear layer thickness to the client’s needs — don’t recommend 12 mil for a commercial setting or expect it to last 10+ years. If your client expects longevity and heavy use, the 20 mil option is clearly the more reliable choice.

How long will a 12 mil wear layer last?

A 12 mil wear layer can last 10 to 15 years with proper care, making it a solid choice for residential environments with moderate foot traffic. It provides enough surface protection for daily activities like walking, light furniture movement, and occasional spills. However, its longevity depends heavily on maintenance practices. Regular sweeping or vacuuming, promptly cleaning spills, and using protective pads under furniture can significantly extend its lifespan. It’s not ideal for commercial spaces, large families, or homes with active pets — in those cases, the floor may begin to show wear and surface damage much sooner. For rental properties or cost-conscious homeowners looking for a balance between performance and affordability, 12 mil is a practical option. Builders and wholesalers should always inform clients that while 12 mil can be durable, it won’t handle the same level of wear and tear as 20+ mil products built for higher-stress environments.

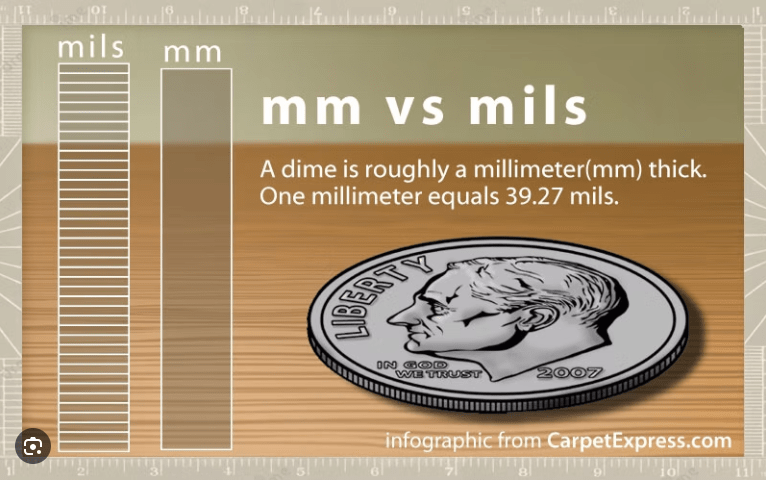

How to read wear layer thickness in inches and mils?

Understanding wear layer measurements is essential for comparing flooring durability. Wear layers are typically measured in mils, where 1 mil equals 0.001 inch. So, a 12 mil wear layer is 0.012 inches thick, and a 20 mil layer equals 0.020 inches. While this may seem small, the difference significantly impacts a floor’s resistance to wear, especially in high-traffic areas. Some brands may also list wear layers in millimeters (mm), where 1 mm = 39.37 mils — so a 0.5 mm wear layer is roughly 20 mils. Be cautious not to confuse the wear layer thickness with the total plank thickness, which includes backing, core, and decorative layers. A 5mm thick vinyl plank might have only a 6 mil wear layer — not very durable. Builders and wholesalers should always verify that the wear layer, not just overall thickness, aligns with the demands of the project.

Is 0.3mm wear layer enough for commercial use?

A 0.3mm wear layer (equivalent to 12 mil) is generally not recommended for commercial use. While it offers sufficient protection for low-traffic residential spaces, such as bedrooms or guest rooms, it lacks the durability needed to withstand the constant foot traffic, rolling loads, and occasional impacts found in commercial environments. In offices, retail spaces, rental units, or hospitality settings, floors are subject to more wear and tear — and a 0.3mm wear layer simply won’t hold up long-term. You may begin to see surface scratches, dulling, or even minor damage within a few years, especially without proper maintenance. For commercial projects, industry professionals typically recommend wear layers of 0.5mm to 0.7mm (20–28 mils) for enhanced scratch resistance and longevity. Builders and wholesalers should guide clients toward thicker wear layers when durability, long-term appearance, and warranty protection are critical to the installation’s success.

Best wear layer choices for kitchen and high-traffic zones

- Kitchens & Hallways: At least 20 mil wear layer (0.5mm)

- Rental Units & Offices: 22–28 mil for extra protection

- Residential Living Rooms: 12–16 mil may be sufficient

Sheet flooring with thick wear layers is great for budget-conscious commercial clients needing quick installs with minimal subfloor prep.

Builders’ checklist: Matching floor specs with real-world use cases

| Project Type | Recommended Wear Layer | Notes |

|---|---|---|

| Residential homes | 12–16 mil | Budget-friendly, lower traffic |

| Retail/Office spaces | 20–28 mil | Strong durability, longer lifespan |

| Rental apartments | 20 mil minimum | Reduces damage claims |

| Kitchens & Wet areas | 20+ mil + waterproof | Vinyl plank or sheet flooring best |

Summary

Choosing the right wear layer is more than a spec — it’s a guarantee of performance. If you’re a builder or wholesaler, knowing this info helps you sell smarter and build better. Got questions or product lines? Feel free to contact me.