Builders today face a constant challenge: rising material costs, unpredictable delivery schedules, and fragmented supply chains. These inefficiencies drain valuable time and resources. The solution is not chasing lower bids across multiple vendors but partnering with a strategic supplier who optimizes procurement at every stage. But how can builders truly save time and reduce costs through smarter material procurement?

Builders can save significant time and money by partnering with a procurement specialist that offers a comprehensive product range, factory-direct pricing, and integrated logistics. With global factories in Vietnam, local U.S. installation teams, and distributor networks, this partnership streamlines sourcing, reduces risks from tariffs, and ensures timely, cost-effective material delivery for every project.

Let’s explore why procurement is often a hidden cost for builders and how the right partnership transforms it into a competitive advantage.

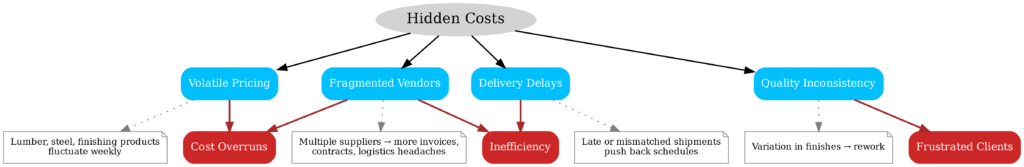

Why Material Procurement Becomes a Hidden Cost for Builders

Material procurement often consumes more time and budget than builders initially estimate. Key challenges include:

- Volatile pricing: Lumber, steel, and finishing products fluctuate weekly.

- Fragmented vendors: Multiple suppliers mean more invoices, contracts, and logistics headaches.

- Delivery delays: Late or mismatched shipments push back project schedules.

- Quality inconsistency: Sourcing from different vendors creates variation in finishes, leading to rework.

What seems like “flexibility” in managing multiple suppliers often results in inefficiency, cost overruns, and frustrated clients.

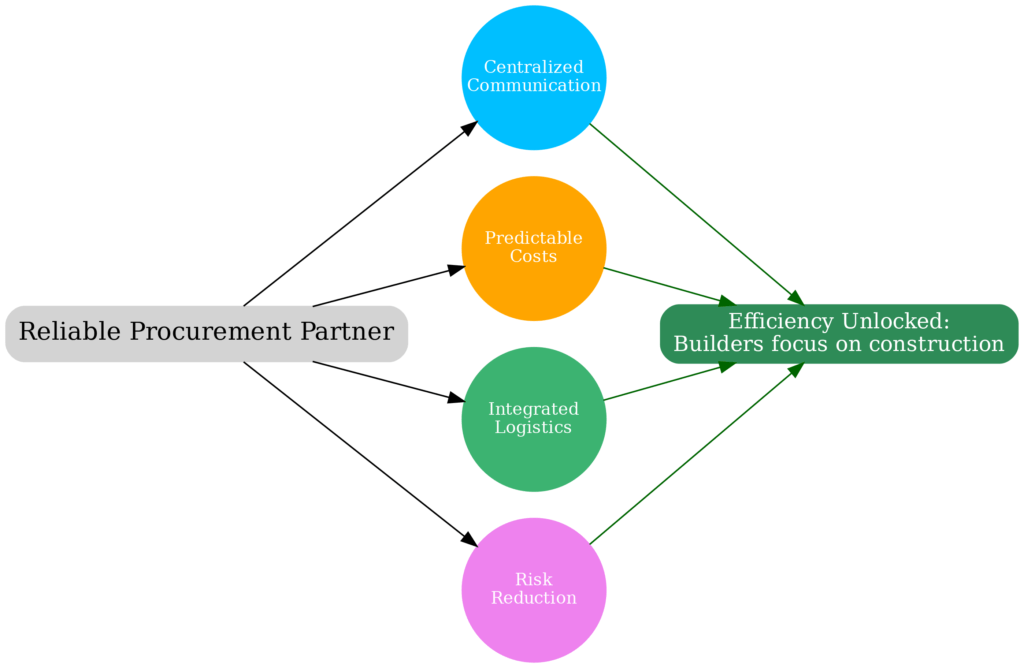

The Value of Partnering With a Strategic Supplier

Partnering with one reliable procurement partner turns complexity into efficiency:

- Centralized communication: One point of contact for all materials.

- Predictable costs: Fixed pricing and volume discounts reduce budget uncertainty.

- Integrated logistics: Consolidated shipments lower freight costs and simplify on-site handling.

- Risk reduction: Strong supplier relationships minimize delays and shortages.

This partnership approach is not about limiting choice—it’s about unlocking efficiency and enabling builders to focus on construction, not supply chain problems.

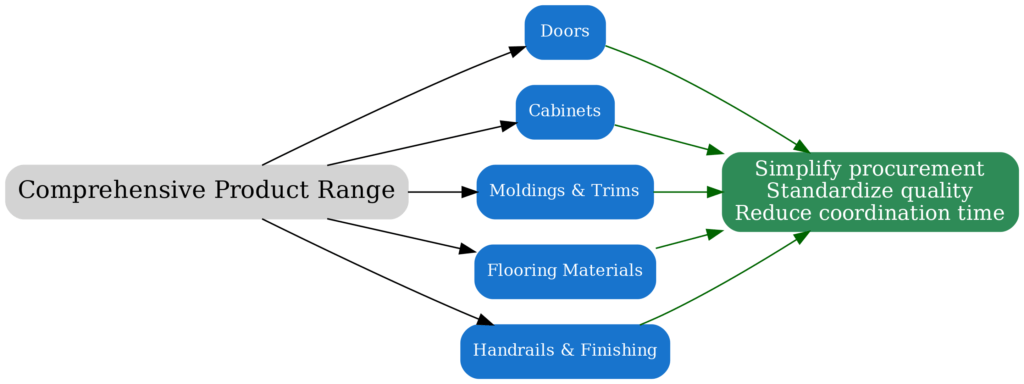

Comprehensive Prodcut Range:Doors,Cabinets,Flooring,and More

A true procurement partner offers a broad portfolio to cover core building needs, including:

- Interior and exterior doors

- Cabinets and customized storage solutions

- Decorative moldings and trims

- Flooring materials suitable for both residential and commercial projects

- Stair handrails and other finishing components

By consolidating these categories into one order, builders simplify procurement, standardize quality, and significantly reduce coordination time.

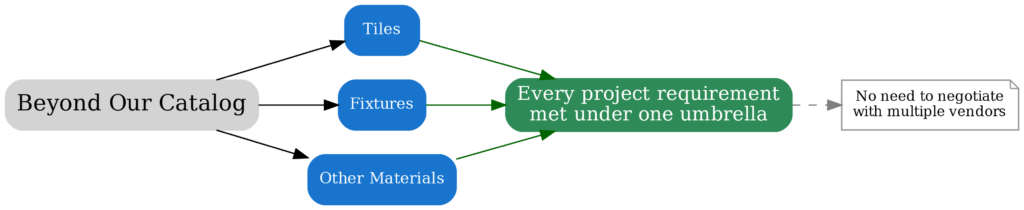

Beyond Our Catalog:Helping You Procure Additional Materials

Even when certain products fall outside our catalog, a trusted partner can source complementary building materials on your behalf. From tiles to fixtures, the procurement process is streamlined so builders no longer need to negotiate with multiple small vendors. This flexibility ensures that every project requirement is met under one umbrella, eliminating gaps that otherwise slow down construction.

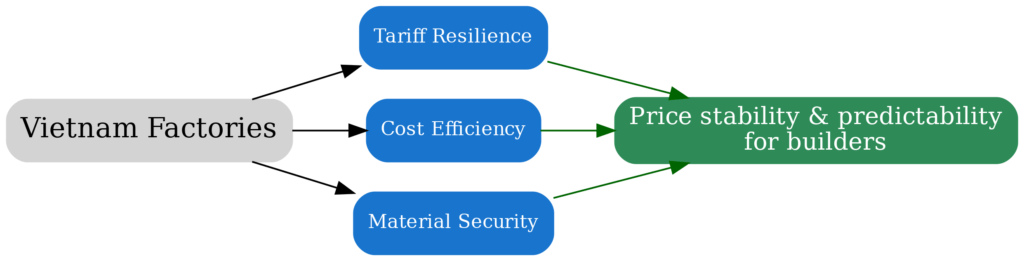

Vietnam Factories:Ensuring Competitive Pricing Despite Tariffs

Global trade dynamics pose a major risk to North American builders. Tariffs and import duties can quickly raise costs. Having factories in Vietnam provides a major advantage:

- Tariff resilience: Competitive pricing remains stable, even when U.S.-China trade policies change.

- Cost efficiency: Factory-direct production eliminates middlemen.

- Material security: With reserves of over 10,000 cubic meters of timber, supply remains reliable.

Builders gain price stability and predictability, essential for winning bids and maintaining profit margins.

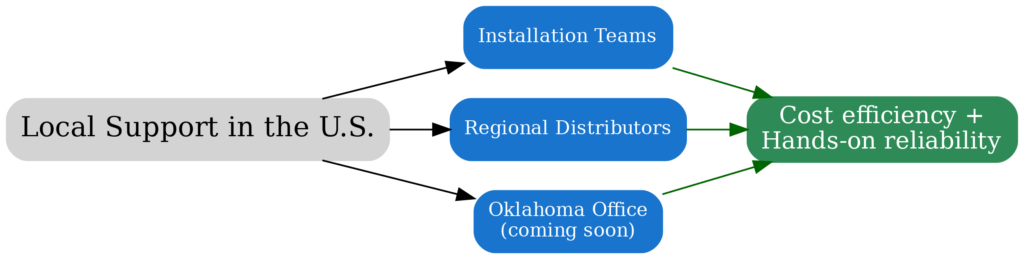

Local Support in the U.S.: Installations, Distributors, and an Oklahoma Office

Global production capacity is most valuable when paired with strong local service. For North American builders, this means:

- Installation teams in the U.S. ensure doors, cabinets, and flooring are properly fitted.

- Regional distributors provide faster access to materials and support.

- A dedicated office in Oklahoma (coming soon) will enhance customer service, technical support, and project coordination.

This hybrid model—global factories with local presence—delivers the best of both worlds: cost efficiency and hands-on reliability.

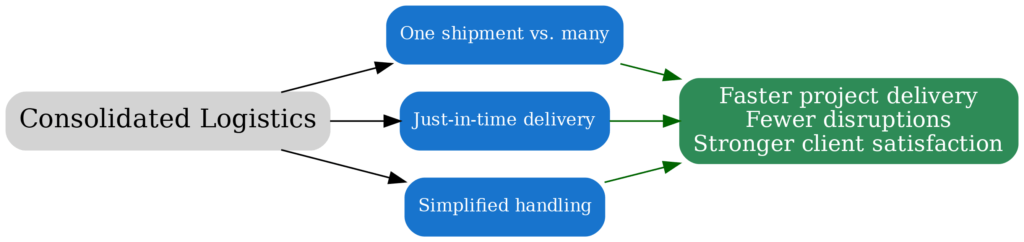

Cost and Time Savings Through Consolidated Logistics

Consolidated procurement does more than reduce paperwork. It creates measurable financial and scheduling benefits:

- One shipment vs. many: Combining materials lowers freight costs.

- Just-in-time delivery: Materials arrive in sequence with project needs, avoiding storage costs.

- Simplified handling: Crews spend less time sorting and more time building.

For builders, these efficiencies translate into faster project delivery, fewer site disruptions, and stronger client satisfaction.

Long-Term Benefits of a Procurement Partnership

Working with a strategic procurement partner is not a one-off transaction—it’s a long-term collaboration that brings ongoing value:

- Stable pricing structures to support consistent bidding

- Quality control across projects, reducing the need for rework

- Shared industry insights on new materials, design trends, and sustainable sourcing

- Mutual growth: As the supplier invests in new U.S. infrastructure, builders gain stronger support networks

Instead of treating procurement as a cost center, builders can view it as a strategic advantage.

Summary

Partnering with a procurement specialist transforms building projects. By offering a broad product range, sourcing additional materials, leveraging Vietnam factories, and providing local U.S. support, the right partner saves builders both time and money. This approach delivers efficiency today and competitiveness for the future.