Rising construction material prices are squeezing builder profits and slowing projects worldwide. Since 2021, costs for steel, wood, cement, and PVC have fluctuated sharply, while logistics and labor expenses continue to climb. For builders, these increases can make it difficult to maintain margins and meet deadlines.

While no one can control global price volatility, smart builders can control how efficiently materials are sourced, purchased, and managed. By locking in prices early with suppliers, buying in bulk, and sourcing directly from factories, it’s possible to stabilize costs and strengthen supply chain control.

In this post, we’ll explore the most effective cost-cutting strategies builders are using right now, and how you can start applying them to keep your projects profitable amid rising prices.

Understanding 2025 Building Material Price Increases

So, why are prices still rising?

According to recent reports on building material price increases 2025, several key factors are at play:

- Global inflation is still above pre-pandemic levels.

- Supply chain lags from 2021–2022 have lingering effects.

- Climate events and raw material shortages are driving up costs for cement, lumber, and insulation.

- Labor shortages are increasing the cost of production and delivery.

Builders should stay informed by tracking price charts monthly and adjusting project estimates accordingly.

Lock in Prices with Suppliers Before Costs Spike

When construction material prices fluctuate rapidly, timing and planning are everything. One of the most effective strategies builders can use is to negotiate fixed-price contracts with trusted suppliers before costs rise.

Securing long-term price agreements provides stability in an unpredictable market. By locking in rates for critical materials like steel, lumber, aluminum, or insulation, you can protect your projects from sudden surges and budget overruns. This approach allows you to forecast expenses with greater accuracy, maintain consistent client pricing, and safeguard profit margins over extended project timelines.

For larger builders, multi-project or annual contracts often lead to additional advantages—such as volume discounts, prioritized inventory allocation, and faster lead times during supply shortages. Even smaller contractors can benefit by collaborating with suppliers who offer fixed-rate packages for recurring orders.

Bulk Purchasing to Offset Long-Term Price Increases

Buying materials in bulk remains one of the most effective strategies for reducing per-unit costs and protecting your business against long-term price volatility. When done strategically, it not only lowers immediate expenses but also secures material availability for future projects.

While many builders hesitate due to upfront capital requirements or limited storage space, careful planning can turn bulk purchasing into a major financial advantage. Partnering with warehouses or negotiating staged deliveries allows you to enjoy volume discounts without overwhelming your inventory capacity. Some suppliers also offer flexible payment terms or financing options that ease cash flow pressure while letting you lock in current prices.

In addition to cost savings, bulk procurement can help you avoid project delays caused by supply chain disruptions. Having a consistent stock of essential items—such as cement, steel rebar, insulation, or door frames—keeps construction on schedule even when market shortages occur.

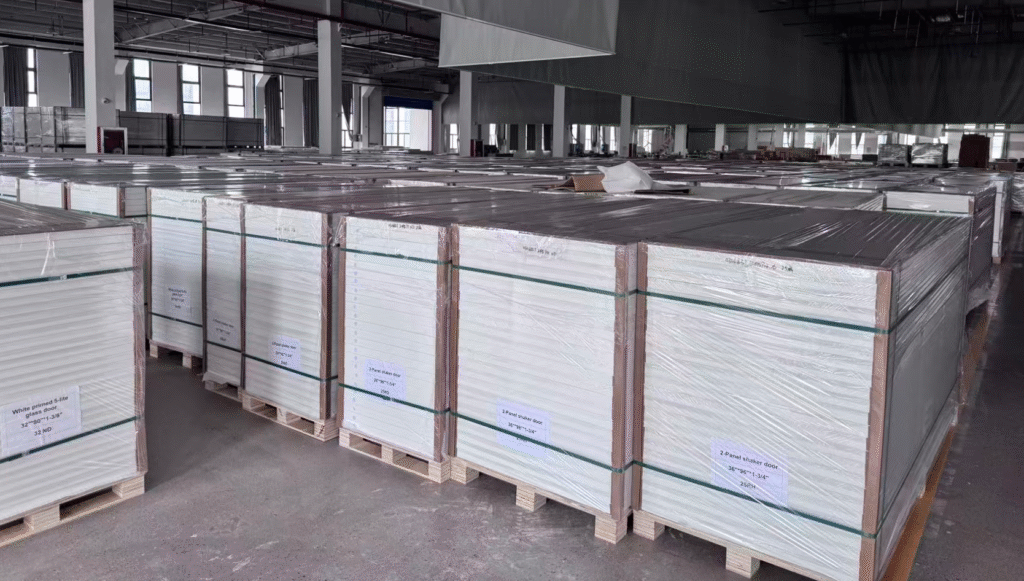

Manufacturers often reward large or repeat orders with benefits like free or consolidated shipping, priority production slots, and customized packaging. For builders managing multiple projects simultaneously, these perks can translate into significant savings and smoother logistics overall.

Tip: Combine bulk purchasing with price-lock agreements to maximize stability. Buying more at fixed rates means lower costs now—and protection from future market spikes.

Source Directly from Factories to Cut Out Middlemen

Middlemen provide convenience, but they also add layers of cost that can quietly erode your profit margins. To stay competitive, more builders are now sourcing materials directly from factories, especially for high-volume, repeat-use items such as tiles, drywall, fixtures, mouldings, and siding.

By working directly with manufacturers, you gain far greater control over pricing, quality, and delivery schedules. Eliminating distributors and wholesalers removes multiple layers of markup, allowing you to negotiate factory rates and tailor orders to your specific project needs. This approach also streamlines communication—you’re speaking directly with the production team, ensuring your requirements on dimensions, finishes, or packaging are clearly understood and met.

Another major advantage is transparency and consistency. Factories can provide detailed production timelines, raw material sourcing information, and product testing data. This helps builders better plan procurement, manage quality assurance, and ensure compliance with local building standards.

For contractors managing multiple projects, long-term partnerships with manufacturers can also bring preferential pricing, priority production slots, and access to customized product lines. International factories, in particular, are often open to developing ongoing supply programs with builders who place regular orders or purchase in container quantities—significantly improving cost predictability and delivery reliability.

Mixed Container Loading: Maximize Every Shipment

For builders sourcing materials from overseas—especially from manufacturing hubs like China or Vietnam, shipping fees can represent a significant portion of total material costs. When freight rates fluctuate, even a small change can heavily impact your overall budget. That’s where mixed container loading becomes a smart and highly effective solution.

Instead of filling an entire container with just one type of product, mixed container loading allows you to combine multiple product categories in a single shipment. This approach maximizes container space, lowers the per-unit shipping cost, and helps smaller orders achieve economies of scale similar to bulk buyers. It also simplifies logistics management by consolidating delivery schedules and reducing customs paperwork for multiple small shipments.

Beyond cost efficiency, mixed loading improves flexibility. Builders can order smaller quantities of different materials as needed without overstocking or waiting for full container quantities. This is especially valuable for projects that require varied finish materials or where on-site storage is limited.

For example, a contractor might combine doors, mouldings, and flooring within the same 40-foot container—optimizing space utilization and cutting overall shipping expenses by up to 30% compared to sending separate loads. Over multiple projects or purchase cycles, this strategy can translate into substan

Are Tariffs Driving Construction Costs?

Many builders are still feeling the impact of U.S. trade tariffs on building materials, particularly those imported from China or Canada.

These tariffs have increased the landed cost of key materials such as:

- Lumber

- Aluminum and steel

- Electrical components

- Cabinets and countertops

While some tariff rates have been adjusted in recent years, the overall impact on construction costs remains significant. Builders importing directly should continue to factor these costs into quotes and profit projections.

Summary

Material costs aren’t going down anytime soon, but smart planning and strategic sourcing can keep your projects profitable in 2025 and beyond.

As a professional factory and building materials supplier, we offer a full range of doors, mouldings, and related construction materials, helping builders source high-quality products directly at factory pricing. Through our integrated product service, you can consolidate multiple categories—such as doors, trims, and flooring—into one shipment, simplifying logistics and reducing overall costs.

Looking to streamline your sourcing or explore customized solutions for your next project? Contact us today to discuss how our one-stop supply service can help you build smarter, faster, and more efficiently.