Facing delays in your construction project? You’re not alone. Poor material sourcing is one of the biggest hidden culprits behind schedule overruns. When deliveries are late or inventory is off, everything grinds to a halt. But with smart material sourcing, builders can finally take control of their timelines.

Smart material sourcing helps builders reduce project delays by aligning material orders with construction schedules, using tools like Gantt charts and procurement software to track inventory, automate deliveries, and improve supplier communication. This ensures materials arrive on time and in the right quantity to avoid costly downtime.

When your timeline is on the line, every delay costs money. Let’s break down how smart sourcing can fix this – one step at a time.

What causes most construction delays?

Construction delays can happen for many reasons, but poor planning and material issues top the list. Common causes include:

- Late deliveries from suppliers

- Inaccurate inventory forecasting

- Change orders due to unavailable materials

- Poor communication between procurement and site teams

- Weather disruptions (less controllable, but impact worsens with bad planning)

Without a solid material procurement strategy, even the best-planned projects can fall apart.

How can material management help avoid delays in construction?

Efficient material management ensures that the right materials are available when and where they are needed. This involves:

- Creating a procurement schedule that matches the construction timeline

- Monitoring inventory levels in real time

- Avoiding overstocking or understocking

- Using centralized platforms for purchase orders and delivery tracking

Smart material sourcing streamlines all these steps, minimizing guesswork and improving site productivity.

How do you solve material shortage problems?

Material shortages usually stem from:

- Rushed procurement

- Lack of supplier backups

- Global supply chain issues

Here’s how to prevent or solve them:

- Forecast demand early – Plan for peak construction phases well in advance.

- Use multiple suppliers – Always have a backup vendor.

- Build buffer stock – Keep reserves for critical materials.

- Use real-time data – Monitor usage trends and re-order before you run out.

- Communicate with vendors proactively – A strong supplier relationship can help you jump the queue when materials are tight.

How does poor procurement affect a construction project?

Poor procurement can derail an entire project. You may face:

- Project pauses due to missing materials

- Increased costs from last-minute purchases

- Wasted labor hours

- Storage issues due to over-ordering

- Damage to your reputation with clients and investors

In contrast, smart procurement ensures seamless material flow, which keeps the project on time and within budget.

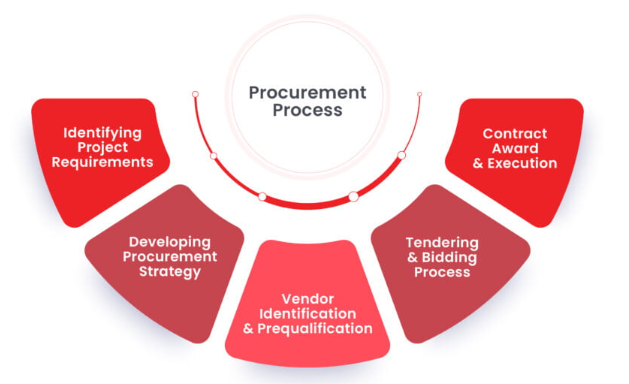

What is smart procurement in construction?

Smart procurement means using digital tools, data analytics, and process automation to improve how materials are sourced, ordered, and delivered.

Key features of smart procurement include:

- Cloud-based platforms to manage vendors and orders

- Integration with project schedules (like Gantt charts)

- Automatic notifications for delays or shortages

- Historical data to improve forecasting

- Mobile apps for on-site teams to request or track materials

It’s not just about buying better — it’s about buying smarter.

How can builders optimize material delivery?

Late or poorly timed deliveries are a major bottleneck. Here’s how to optimize them:

- Schedule deliveries based on project phases, not just availability

- Use delivery tracking software to monitor ETA in real time

- Consolidate shipments to reduce handling costs

- Plan for site storage – ensure there’s space before it arrives

- Avoid premature deliveries – having materials too early can cause clutter and damage

A good material sourcing strategy ensures deliveries arrive just-in-time, not too early or too late.

How to improve procurement in construction?

Improving procurement starts with shifting from reactive to proactive planning. Here’s how builders can level up:

- Start sourcing early – Don’t wait until the last minute

- Create procurement schedules linked to your project plan

- Train procurement teams to use digital tools effectively

- Audit supplier performance regularly

- Track and analyze procurement data for continual improvement

With these steps, procurement becomes a strategic asset—not just an operational task.

How can builders handle construction supply chain issues?

Supply chain disruptions have become more common due to global events, tariffs, and material scarcity. To manage this:

- Diversify suppliers to avoid single points of failure

- Use local sourcing when possible to reduce transit risk

- Leverage data analytics to predict shortages before they happen

- Negotiate flexible contracts to adjust quantities or timelines

- Collaborate closely with suppliers and logistics teams

Smart builders don’t wait for a crisis—they prepare for it.

Wrapping Up: Build Smarter, Not Slower

Project delays are often avoidable — if builders take control of their material sourcing. With smart procurement tools, better forecasting, and closer supplier relationships, construction projects can stay on schedule and under budget.

Make the shift today — because time really is money in construction.