For builders working on custom projects, sourcing materials can be a challenge. Traditional suppliers often require large minimum order quantities (MOQs), leading to excess inventory and wasted resources, especially for smaller or specialized jobs.

Flexible MOQ policies offer a solution, allowing builders to purchase only what they need for each project phase. This flexibility reduces costs, minimizes waste, and ensures timely delivery of materials, which is crucial for custom projects where material needs may shift. For this type of project, a flexible MOQ policy is needed.

Building on this flexibility, mixed container shipping services further support custom project needs by allowing builders to consolidate materials into one shipment. This combined approach optimizes both procurement and logistics, ensuring builders can manage costs and timing more efficiently throughout the entire process.

Why Flexibility in MOQ Matters for Builders?

In custom construction projects, the need for materials can vary greatly depending on the design, scope, and timeline of the job. Traditional suppliers often impose large MOQs, forcing builders to purchase materials in bulk—far beyond what is needed for a specific project. This creates multiple problems for builders:

- Excess Inventory and Waste: Builders are often left with surplus materials that go unused, leading to waste and unnecessary costs. Storing and managing excess stock also adds overhead costs, especially when dealing with specialized items that are unlikely to be used on future projects.

- Increased Cash Flow Pressure: Large MOQ requirements demand a significant upfront investment, which can be particularly challenging for builders managing multiple projects at once. The cash tied up in excess inventory can impact their ability to move funds between projects or respond to unexpected costs.

- Limited Flexibility with Changing Project Requirements: Custom projects, by nature, are often subject to changes in scope or design as the project progresses. Flexible MOQs allow builders to respond quickly to shifts in project needs—whether that means ordering fewer quantities of materials or sourcing new materials mid-project without financial strain.

- Lower Risk of Overbuying: With traditional MOQs, builders may be forced to purchase excess quantities to meet the minimum requirement, even if the material is only needed in small amounts. Flexible MOQs ensure that builders only pay for the materials they will actually use, improving cost efficiency and reducing unnecessary risk.

Ultimately, flexibility in MOQ policies empowers builders to align their material orders with actual project requirements, creating a more sustainable and cost-effective way to manage custom construction projects. This approach also reduces the risk of material wastage and ensures that budgets stay on track without tying up unnecessary funds in inventory.

How Mixed Container Shipping Services Help Builders

Mixed container shipping services simplify logistics by allowing builders to consolidate materials from multiple suppliers into a single shipment. This approach reduces the complexity of managing multiple deliveries and minimizes shipping costs, offering several key benefits:

- Cost Savings: By pooling resources and sharing container space with other buyers, builders can significantly reduce their shipping expenses, making it a more cost-effective option than ordering from each supplier separately.

- Simplified Logistics: Builders can avoid the headache of managing multiple shipments. With mixed container shipping, they receive everything they need in one consolidated shipment, making inventory management easier.

- Faster Delivery: By consolidating shipments, delivery times are more predictable and streamlined, helping ensure that materials arrive on time and that projects remain on schedule.

For builders who need materials from various suppliers, mixed container shipping provides an efficient, cost-effective solution that enhances project planning and keeps everything moving smoothly.

Benefits of Mixed Container Shipping

The advantages of mixed container shipping extend beyond cost savings:

- Improved Inventory Control: Builders can track one shipment rather than juggling multiple deliveries, reducing the risk of misplaced or delayed materials.

- Better Customization: Custom projects often require materials from different suppliers. Mixed container shipping allows builders to meet unique project needs by consolidating orders into one container.

- Environmental Impact: Fewer shipments mean a reduced carbon footprint, making mixed container shipping a more sustainable option compared to separate deliveries.

Supporting Customization and Project Flexibility

Custom projects are inherently dynamic, with evolving designs and changing client needs. Flexibility is key to keeping everything on track. Flexible MOQs and mixed container shipping services support builders in adapting to these shifts without the challenges posed by bulk ordering or complex shipping schedules.

- Adapting to Design Changes: As custom projects often undergo design changes, flexible MOQs make it easier for builders to order additional materials in small quantities without the financial strain of over-ordering. Similarly, mixed container shipping lets them source materials quickly from different suppliers, even mid-project.

- Ensuring Timely Completion: Both flexible ordering and streamlined shipping keep materials flowing efficiently, ensuring that the project stays on track and deadlines are met.

This combination of flexibility and efficiency ensures that custom projects, no matter how fluid, stay within budget and are completed on time.

Our Service: Mixed Loading Service

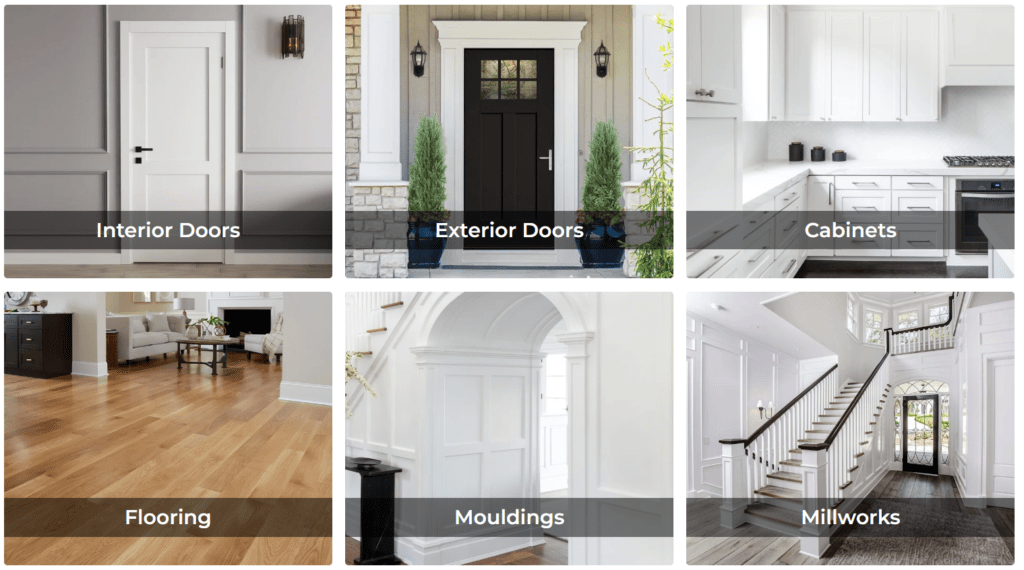

At UWG, we recognize the complexities of sourcing multiple materials from different suppliers for custom projects. To simplify this process, we offer our Mixed Loading Service, which allows builders to conveniently purchase a variety of building materials in one place. Whether you’re in need of doors, moldings, floors, cabinets, or other essential materials, our service provides a one-stop solution that meets all your needs.

With our Mixed Loading Service, we combine all the necessary products for your project into one container, which is then shipped directly to you. This ensures that you have everything you need to move forward with your project, saving you time and reducing the hassle of coordinating with multiple suppliers.

Advantages of Our Mixed Loading Service:

- One-Stop Shopping: Get everything you need from UWG, saving you time and effort.

- Cost Efficiency: By combining shipments, we lower your overall shipping costs.

- Simplified Logistics: Receive all materials in one shipment, eliminating the need to track multiple deliveries.

- Faster Turnaround: Enjoy on-time delivery, keeping your project on schedule.

- Flexibility: Order only what you need in the right quantities, with no bulk requirements.

- Reliable Delivery: We ensure your materials arrive together, on time, and ready for use.

With our Mixed Loading Service, we aim to make your procurement process simpler, more cost-effective, and more efficient, so you can focus on delivering top-quality projects for your clients.

Summary

Flexible MOQ policies and mixed container shipping services are transforming how builders manage custom projects. With the ability to order materials in smaller quantities and streamline the shipping process, builders can reduce costs, minimize waste, and maintain greater control over project timelines. These solutions enable builders to remain agile and responsive to the changing needs of custom projects while ensuring quality and efficiency. By embracing these modern strategies, builders can deliver on-time, on-budget results—every time.