In multi-unit residential projects, interior doors are not simply aesthetic elements—they directly influence sound transmission, fire safety, installation timelines, tenant comfort, and lifecycle cost. For builders and wholesalers managing hundreds of openings across apartments, condos, or townhomes, poor door specification can lead to inspection delays, tenant complaints, and costly rework.

So how do you choose the right door for the right unit, without increasing complexity or blowing your budget?

The answer lies in aligning door performance (acoustic and fire ratings), layout constraints (swing clearance, frame depth), and material durability with unit function and tenant expectations. Choosing the right door type—swing, barn, pocket, sliding, or fiberglass—is just the beginning. The key is standardization across sizes, hardware, and finishes to streamline procurement, reduce error, and control cost per door.

This guide walks through the critical decision points for professionals selecting interior doors in multi-family developments—combining technical specs with procurement strategy and design integration.

1. Understand Housing Types and Usage Needs

In multi-family residential construction, understanding the typology of the building is essential to selecting doors that meet both functional and regulatory demands. Each housing category—apartments, condos, and townhomes—has unique priorities when it comes to interior door performance and specification.

- Apartments Typically designed for rental markets with high occupancy turnover, apartments prioritize cost-efficiency, durability, and low-maintenance finishes. Doors should be selected for quick installation (e.g., pre-hung MDF or hollow core), ease of replacement, and resistance to daily wear. STC ratings of 27+ are recommended for bedroom and bathroom doors to ensure adequate sound separation between units. In high-rise apartments, fire-rated doors (20-minute minimum) may also be required for corridor-facing units.

- Condos Since condos are individually owned, buyers expect elevated finish quality and long-term performance. Interior doors in condos should balance aesthetics, acoustic control, and code compliance. Solid-core swing doors or architectural-grade MDF with factory finishes are common. Incorporating glass panel inserts or custom profiles can align door designs with overall unit aesthetics. Soundproofing is a higher priority here—STC 30+ may be specified in luxury developments.

- Townhomes As low-density, often multi-story units, townhomes offer more design flexibility. Builders often have more freedom to select style-matched door systems that reflect the overall architectural character (modern, farmhouse, traditional). Due to their residential feel, doors are expected to be more substantial in weight, with solid wood or fiberglass options used for durability. Unlike apartments, barn doors or French doors may be used decoratively in main living areas or master suites.

Door selection across these housing types must align with layout constraints, acoustic targets, fire and egress codes, and the buyer or tenant’s expectations. Each decision impacts long-term maintenance, resale value, and project cost per unit.

2. Interior Door Types: Functional Roles and Specification Guidance

Interior doors in multi-unit residential buildings must be selected not only for appearance but also for space efficiency, installation feasibility, lifecycle cost, and compliance with building codes. Below is a breakdown of four major door types commonly used in apartments, condos, and townhomes, with professional insight into their best-use scenarios.

🔹 Swing Doors (Hinged Doors)

The most prevalent interior door type in North America, swing doors are mounted with butt hinges and open into or out of a room, following specific clearance requirements.

Key Characteristics:

- Code-Compliance: Supports ADA and fire egress standards when sized appropriately (e.g., 36” wide for accessible units)

- Performance: Solid-core variants offer superior STC ratings (≥27), ideal for sound-sensitive areas like bedrooms or bathrooms

- Installation: Quick to install when pre-hung; requires full swing clearance

Recommended Use: Universal in application—bedrooms, bathrooms, closets, mechanical rooms across all housing types

🔹 Barn Doors

Surface-mounted sliding doors that operate on an overhead track. Aesthetic-driven but with spatial and acoustic tradeoffs.

Key Characteristics:

- Space Efficiency: Eliminates swing clearance but requires adjacent wall space equal to door width

- Limitations: No perimeter seal = poor acoustic and privacy performance (STC rating usually <20)

- Style Appeal: Popular in modern farmhouse, loft, and transitional designs

Recommended Use: Closets, home offices, decorative partitions in townhomes or high-end condos—not suitable for bedrooms or bathrooms where privacy is essential

🔹 Pocket / Sliding / Bifold Doors

These concealed or space-saving systems are used to resolve clearance issues in compact layouts.

Key Characteristics:

- Pocket Doors: Slide into wall cavity; optimal for small bathrooms or laundry areas but require framing depth (≥3.5” nominal wall thickness)

- Sliding Doors: Wall-mounted, may be single-track or bypass; good for closets

- Bifold Doors: Fold in panels; cost-effective but prone to misalignment over time

Code Note: Pocket doors may not be allowed in certain fire-rated assemblies—always verify local code

Recommended Use: Closets, powder rooms, pantries, secondary bathrooms—especially in apartments and studio units

🔹 Fiberglass Doors

An engineered option growing in interior use due to its dimensional stability and moisture resistance.

Key Characteristics:

- Durability: Resistant to warping, swelling, cracking—ideal for laundry rooms and bathrooms

- Aesthetic Flexibility: Available in wood-grain textures or paint-ready smooth finishes

- Thermal/Acoustic Insulation: Comparable to solid wood or solid-core MDF

3. Materials & Core Types: Technical Performance & Application Strategy

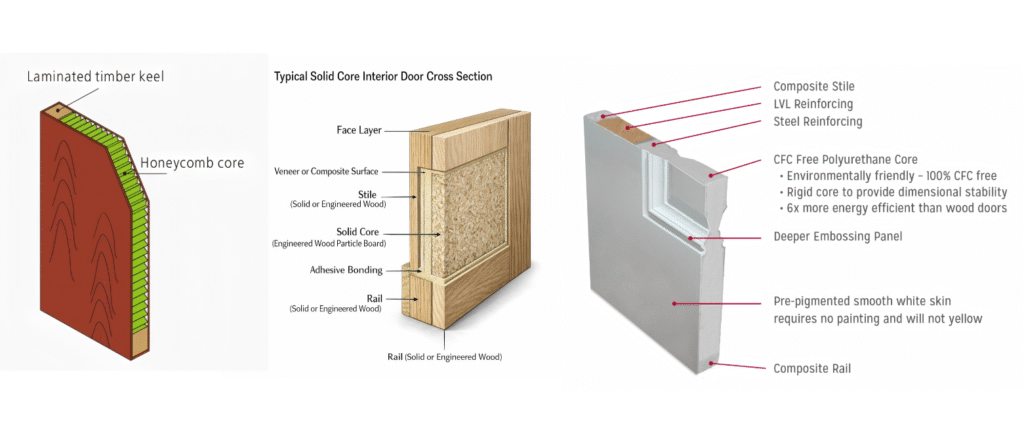

Interior door cores and materials determine long-term durability, sound attenuation, environmental resistance, and cost per unit. Choosing the right combination depends on room function, humidity exposure, and fire/sound code requirements.

| Material | Technical Features | Applications | Considerations |

|---|---|---|---|

| Hollow Core | Lightweight honeycomb or particleboard fill | Closets, low-traffic interiors | Low STC (<20), not moisture-resistant |

| Solid Core | Engineered wood or particleboard core | Bedrooms, bathrooms | STC 27–32, supports fire-rating |

| MDF / HDF | Medium/high-density fiberboard; smooth, stable | Painted interiors, flush designs | Not waterproof; needs sealing in wet zones |

| Solid Wood | Natural wood core and frame | High-end homes, visible doors | High cost, may warp if unsealed properly |

| Fiberglass | Molded composite with polymer skin | Laundry, bathrooms, wet zones | Resistant to warping, cracking, delamination |

| PVC / Composite | Synthetic or wood-poly blend | Rental units, utility rooms | Termite-resistant, low-maintenance |

4. Size, Swing & Door Configuration Standards

Correct door sizing and swing planning is essential to meet accessibility codes, reduce construction clashes, and ensure tenant comfort.

📐 Standard Door Sizes (US/North America)

| Application | Standard Widths | Height | Notes |

|---|---|---|---|

| Closets, pantries | 24″–28″ | 80″ (6′8″) | Narrow; may use bifold/sliding |

| Bedrooms, bathrooms | 30″–32″ | 80″ | Swing or pocket doors typical |

| Accessible (ADA) units | 36″ | 80″–84″ | 32″ net clear required; lever handle required |

🚪 Swing & Operation Configurations

Selecting the correct swing direction and opening mechanism reduces construction conflicts and enhances user experience.

➤ Left-Hand / Right-Hand Swing

- Most common in bedrooms, bathrooms

- Requires 32″ net clear width in accessible units

- Verify clearance against walls, fixtures, and furniture

➤ Double Swing / French Doors

- Used in master bedrooms, living-dining transitions

- Adds symmetry and openness, but needs wide openings (≥5 ft)

➤ Pocket Doors

- Slide into wall cavity; save floor space

- Minimum 2×4 or 2×6 wall required, depending on hardware

- Check for fire wall restrictions—often not allowed in rated corridors

➤ Sliding & Bypass Doors

- Wall-mounted or track-based; ideal for closets

- Use high-quality rollers to prevent derailment in long-term rentals

➤ Bifold Doors

- Foldable panels on top/bottom tracks

- Economical for closets; limited use in luxury applications

5. Aligning Door Selection with Unit Design Styles

A coherent interior design language across all units adds perceived value and improves resale or leasing appeal. Interior doors play a critical role in reinforcing these style narratives. Here’s how door types align with dominant design categories in North American multi-family construction:

| Design Style | Recommended Door Solutions | Rationale |

|---|---|---|

| Modern / Minimalist | Flush MDF, sliding, fiberglass | Clean lines, flat profiles, concealed hardware—doors should disappear into the wall plane |

| Traditional | Raised panel swing, French doors | Symmetry, molding details, period-consistent proportions |

| Industrial / Loft | Barn doors, steel-trimmed slab doors | Exposed hardware, darker finishes, visible fasteners, urban textures |

| Luxury / Custom | Solid wood, glass inset swing, double French | Premium materials, larger dimensions, hardware coordination with high-end fixtures |

6. Procurement & Bulk Installation Efficiency

Efficient door procurement in multi-unit construction is not only about cost—it’s about minimizing logistical friction, ensuring consistent quality, and avoiding downstream rework. Below are the key strategies builders and wholesalers should apply:

📦 Standardization First

- Pre-hung systems reduce labor time and eliminate on-site frame alignment errors.

- Specify consistent wall and frame thicknesses across units to avoid mix-ups.

- Standardize:

- Swing direction (e.g., right-hand open inward for all bedrooms)

- Hinge and latch locations (pre-drilled)

- Hardware types (lever vs knob, finish, fire-rating)

🔗 Work with Volume-Capable Suppliers

- Engage suppliers who can deliver:

- Multi-phase shipments aligned with build schedule

- Packaging by unit or floor

- Labeling per floorplan

- Examples include:

- Home Depot Pro B2B

- Builders FirstSource

- National Door Distributors with ERP integration

🧮 Cost & Timeline Control

- Secure quotes for entire door packages early in design stage.

- Lock in lead times (typically 6–10 weeks for custom pre-hung).

- Allocate 2–4% overage in ordering to account for damage or changes.

- Coordinate delivery to minimize on-site storage needs.

7. Installation & Maintenance: Risk Reduction & Lifecycle Planning

Proper installation is critical to long-term door performance. In multi-unit projects, even minor deviations can scale into costly rework.

🛠️ Common Installation Pitfalls:

- Frame misalignment (±3mm): Causes latch failure, leaf binding, or visible light gaps

- Incorrect swing configuration: Often results from mirrored unit plans—use floor plan keys and pre-stamped door tags

- Non-standard hardware: Mixing latch depths, hinge backsets, or finish types complicates maintenance and replacements

🔄 Maintenance Strategy:

- Durable finishes: Use factory-coated or laminate skins in high-traffic corridors

- Replaceable components: Specify hinges and handles with readily available SKUs for rental turnover

- Lifecycle expectations:

- Hollow-core doors: 6–8 years (light duty)

- Solid-core or fiberglass: 10–15 years (moderate to high use)

- Maintenance records: Log serials, swing types, install dates for asset management

📌 Tip: For high-turnover rental units, opt for surface-repairable doors (e.g., MDF with touch-up kits) over veneered wood, which is more prone to delamination.

8. Regulatory & Performance Compliance

Interior doors in residential developments must meet a range of code-driven requirements. Failing to comply can lead to inspection delays or failed certifications.

🔒 Fire-Rating

- Minimum 20-minute label: Required for unit entries facing corridors (per NFPA 80)

- 45-minute: May be required adjacent to stairwells or shared utility rooms

- Frame, core, label, and hardware must all match UL-listed assembly specs

🔇 Acoustic Control

- STC ≥ 27: Bedrooms, bathrooms (per ANSI/ASA S12.60)

- STC ≥ 30–32: Higher-end or urban infill projects near traffic/noise

- Use solid-core with perimeter seals for optimal control

♿ Accessibility (ADA)

- 36″ nominal width: Results in ≥32″ clear opening (ADA Section 404)

- Hardware: Lever-type, operable with one hand, no tight grasping

🌱 Environmental Requirements

- CARB Phase 2: Applies to MDF/HDF core doors (limits formaldehyde)

- LEED v4.1: Option to gain points via low-emitting materials or FSC-certified cores

✅ Conclusion

Interior door systems directly impact not just how a space looks—but how it performs over decades. In multi-unit housing, strategic door selection influences:

- Noise insulation and tenant satisfaction

- Fire safety and inspection readiness

- Installation efficiency and error reduction

- Maintenance cost and operational turnover

- Regulatory approval and green building compliance

Builders and wholesalers who plan doors as systems—not just materials—gain an edge in efficiency, scalability, and long-term asset value. Whether you’re outfitting 50 units or 500, the right combination of type, spec, and supplier makes a measurable difference.

📞 Looking to standardize your next project’s door package? We can help you scope, spec, and scale door solutions tailored to your layout, budget, and build schedule

Articles that you may be interested in:

Front Door Ideas: Upgrade Your Home’s Entrance with Style and Security

Do Doors Have Standard Sizes? What Builders Need to Know Before Ordering

Shaker Door Panel Thickness Guide: Standard Sizes and Custom Options