Contractors can’t afford mistakes when it comes to fire safety. The wrong hardware on a fire-rated door can lead to inspection failures—or worse, real danger. Choosing the correct certified components ensures code compliance and protects lives. Here’s how to select fire door hardware that meets safety standards and project needs.

To choose the right fire door hardware, assess the building type and its occupancy, check compatibility with the door/frame, and confirm certifications like UL or CE. Fire doors must include closers, hinges, and secure locks or latches. Refer to NFPA 80 guidelines, and always consult a fire safety expert for large projects or unusual layouts.

Let’s break down what to look for, the key standards to follow, and common pitfalls contractors should avoid when specifying fire door hardware.

How to choose the right door hardware?

When selecting fire door hardware, your first priority should always be code compliance and performance under fire conditions. But it’s not just about fire ratings—it’s also about durability, compatibility, and usage.

Here’s what to consider:

- Compatibility: The hardware must be designed for fire-rated doors. That includes proper size, weight handling, and operational design. For example, a hydraulic closer meant for an interior wood door may fail on a heavy steel fire door.

- Durability: High-traffic areas (like schools or hospitals) demand Grade 1 commercial hardware. It’s tested for durability and high-use cycles.

- Accessibility and ADA Compliance: Make sure handles and latches meet accessibility standards.

- Security: Always consider whether the hardware also needs to serve security functions—like controlled access, alarms, or delayed egress systems.

Tip: Coordinate hardware schedules early in the project to prevent change orders due to non-compliant or incompatible specs.

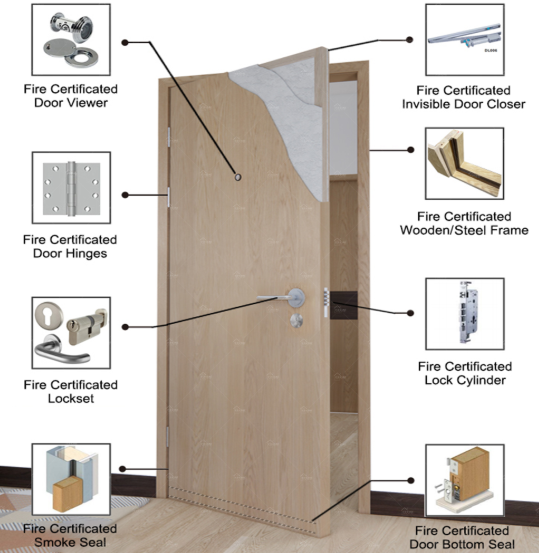

What hardware is required on a fire door?

Every certified fire door must include three critical hardware components:

- Hinges: At least three fire-rated hinges are required. These must be steel (not brass or aluminum) and cannot have ball bearings exposed to fire.

- Self-Closing Device: Fire doors must always close on their own. This is usually a door closer—either surface-mounted or concealed. It must be strong enough for the door’s size and weight.

- Lock/Latch Mechanism: To maintain integrity during a fire, the door must stay latched. Use UL-listed fire-rated locks or latches that withstand heat and pressure.

Additional items might include:

- Panic bars or exit devices (for corridors or egress routes)

- Smoke seals or intumescent strips

- Automatic drop seals for sound/fire performance

- Electric strikes or maglocks (must fail-safe and comply with NFPA 101)

Important: Never install doorstops or kick-down holders on fire doors—they disable the closing function and void certification.

Do I need FD30 or FD60?

FD ratings refer to how long a fire door can withstand fire before failing:

- FD30: Resists fire for 30 minutes

- FD60: Resists fire for 60 minutes

Which one you need depends on your building type, use, and fire risk.

When to use FD30:

- Residential settings

- Offices

- Doors on escape routes (where 30 minutes is sufficient for evacuation)

When to use FD60:

- Industrial facilities

- Large public buildings

- Stairwells in multi-story buildings

- High-value areas or rooms with hazardous contents

What should door hardware match?

Beyond safety and certification, contractors often ask: Should hardware finishes match?

The short answer: function over form, but visual consistency still matters.

Here’s how to think about it:

- Aesthetics: Match metal finishes (brushed stainless, polished chrome, bronze) to align with other fixtures (lights, handrails, taps).

- Project scope: In commercial or public projects, mismatched finishes are usually unacceptable.

- Functionality: Never compromise fire rating just to match finishes. Fire-rated hardware is available in a variety of finishes—always check the datasheet.

Design tip: Select the finish after you’ve verified the hardware meets fire requirements. Not before.

What are the fire rated door hardware requirements?

To meet international standards (NFPA 80, UL10C, BS EN 1634-1), your hardware must:

- Be third-party tested and certified

- Be labeled with fire rating (visible after installation)

- Be installed exactly as tested—any modifications void the certification

Hardware must meet:

- UL or CE markings (depending on region)

- Grade 1 ANSI/BHMA for heavy commercial use

- Self-closing compliance (NFPA 101)

- Correct latch throw length (per NFPA 80, minimum 1/2″)

- Common fails during inspections:

- Hardware not properly labeled

- Missing closer arms

- Field modifications not approved

- Propping doors open

What is NFPA 80 and why does it matter?

NFPA 80 is the U.S. national standard that governs the installation and maintenance of fire doors and other opening protectives.

Why it matters to you:

- It outlines minimum hardware requirements

- Specifies installation methods (no drilling unless pre-approved)

- Requires annual inspections

- Prohibits modifications that alter door performance

- Sets rules for clearances, gaps, and labeling

Contractors must follow NFPA 80 to pass fire inspections. Even certified hardware installed incorrectly can lead to code violations.

What changed in fire door hardware standards since 2022?

Several updates since 2022 have affected fire door specifications:

Key Changes:

- Stricter enforcement of annual fire door inspections

- Digital door labels with QR code traceability

- New electrified hardware options must meet additional testing

- Increased emphasis on self-closing mechanisms that function under temperature extremes

What this means for contractors:

- Keep up to date with manufacturer installation instructions

- Ensure any electronic access hardware is fire-rated and fails-safe

- Document hardware specs and installation for inspection reports

Remember: fire rated door hardware requirements evolve. What passed in 2022 might not pass in 2025.

Summary

Fire door hardware isn’t just about fittings—it’s about protecting people and passing inspections. Use certified components, follow NFPA 80, and always double-check compatibility. Have questions or tips? we’re here to learn together.