Interior doors often appear deceptively similar on the surface, but their long-term performance, durability, and reliability vary significantly depending on how they’re built, finished, and installed. For builders, contractors, and wholesalers sourcing products at scale, a poorly chosen interior door can lead to frequent callbacks, damaged reputations, and increased total cost of ownership. A well-constructed door, on the other hand, can withstand years of wear, support heavy use, and maintain its integrity across all climate conditions. But what exactly defines a high-quality interior door?

A high-quality interior door requires a solid core like MDF or laminated wood, frame components made from stable, moisture-resistant materials, and slab thickness of no less than 1-3/4″ for strength. All joints must be reinforced to prevent cracking. Hardware should meet Grade 1 or 2 performance, and the surface must use industrial coatings that resist abrasion, stains, and humidity. Proper edge sealing ensures dimensional stability over time. Only when all components meet these standards can durability and appearance be guaranteed.

In this article, we will explore in depth how to assess interior door quality from a construction and material science perspective, referring to ASTM, ANSI, and WDMA standards throughout.

Structure: What’s Inside the Door Matters Most

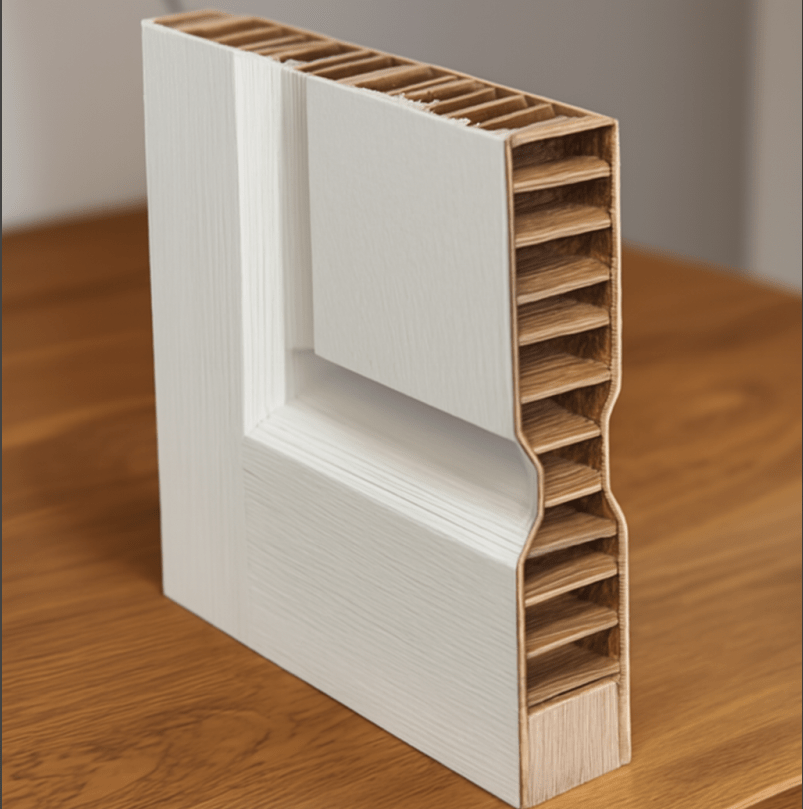

The first and arguably most critical element is the door’s structure. This is what gives the door its physical integrity. Inferior doors often fail because of weak internal cores, unstable framing, and inconsistent manufacturing. The core material—what’s inside the slab—affects everything from sound transmission to screw-holding capacity to how the door reacts to humidity.

Type of core

Hollow core

Common low-cost doors use honeycomb paper cores. This material is inexpensive and lightweight but lacks any significant mass, resulting in low acoustic performance (STC ratings below 22), vulnerability to impacts, and high susceptibility to warping. Doors with this construction are not suitable for high-traffic commercial applications or multi-family housing where durability matters.

Soild core

Solid core doors offer far superior performance. These may be made of medium-density fiberboard (MDF), particleboard, or stave lumber. MDF cores provide a uniform, dense fill that takes paint well and offers moderate sound insulation (STC 27–30). Stave lumber cores use laminated wood strips, providing superior stability, better resistance to warping, and excellent screw-holding power—ideal for heavier commercial hardware. Mineral cores, though less common, are necessary for fire-rated doors and meet ASTM E152 standards for fire endurance.

Stile&rail

In addition to the core, the stile and rail construction matters. Cheap doors may use MDF stiles or low-density Cunninghamia lanceolata , both of which are commonly selected due to their low cost and ease of machining. However, MDF lacks adequate screw-holding capacity and is highly vulnerable to moisture absorption, leading to swelling, cracking, and structural instability—especially around hinge and lock areas. Fir, while slightly better in mechanical strength, tends to be soft, resinous, and dimensionally unstable under varying humidity conditions. These materials are often responsible for complaints such as loose hinges, misalignment, or cracking under load after installation.

By contrast, high-quality doors use laminated veneer lumber (LVL) or finger-jointed pine in the stile and rail assembly. LVL offers superior strength-to-weight ratio, high dimensional stability, and consistent structural integrity across long spans. Finger-jointed pine, particularly from mature, kiln-dried sources, ensures excellent screw retention and low deformation. These materials meet or exceed the performance criteria outlined in WDMA I.S.1A for engineered wood components used in door assemblies.

Our factory uses only New Zealand radiata pine finger-jointed lumber for the stiles and rails of our interior doors, selected for its high density, straight grain, and proven resistance to warping and cracking. For exterior doors, we incorporate LVL, engineered hardwood, and moisture-sealed composite structures to ensure long-term performance in demanding outdoor environments.

This combination not only guarantees mechanical reliability but also enhances long-term product consistency—an essential factor for professional builders and contractors who expect predictability on every project.

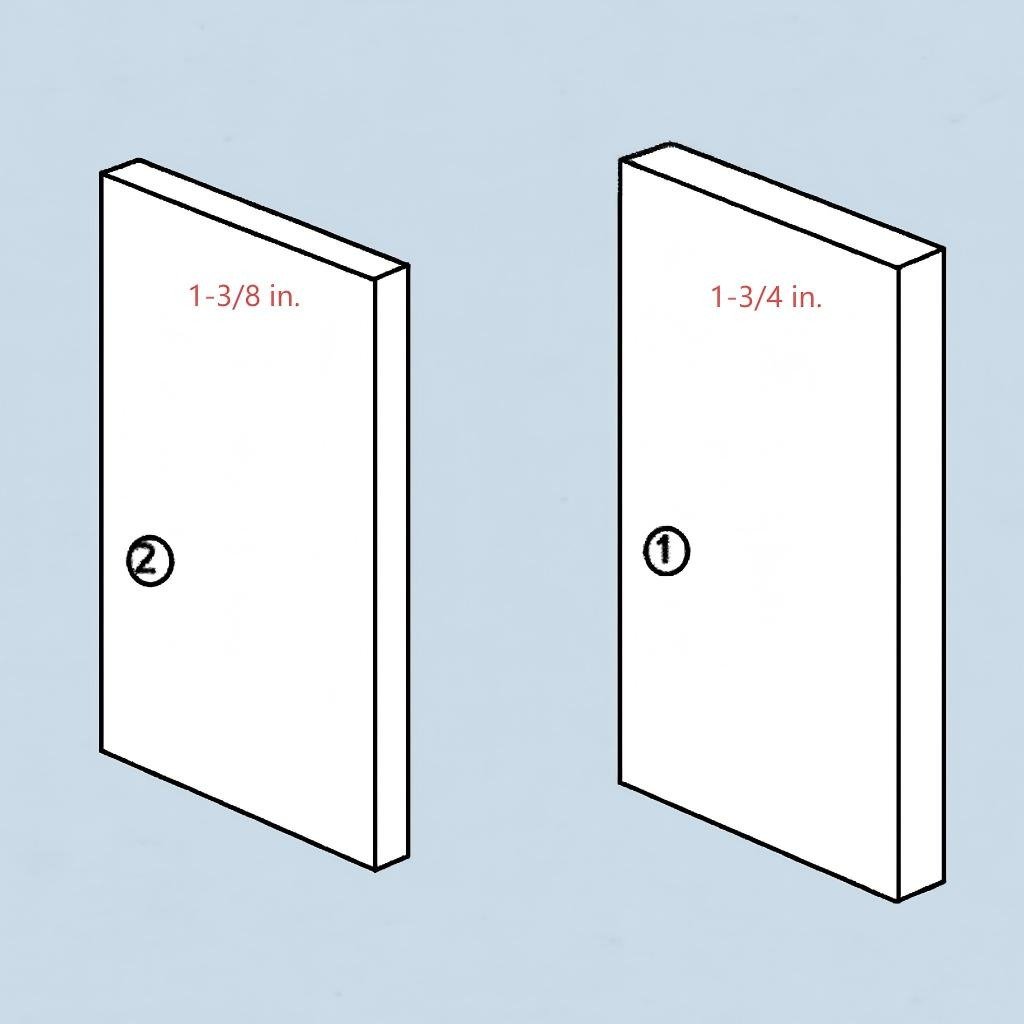

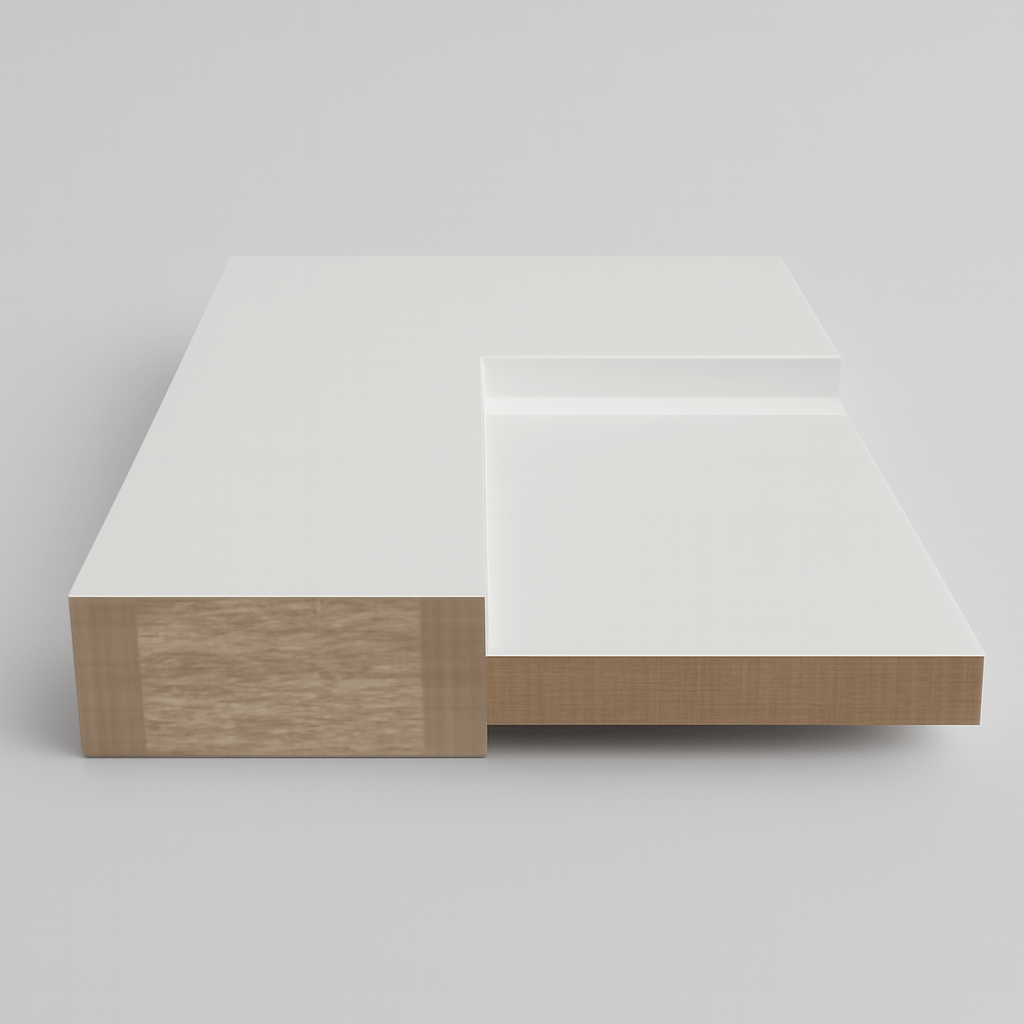

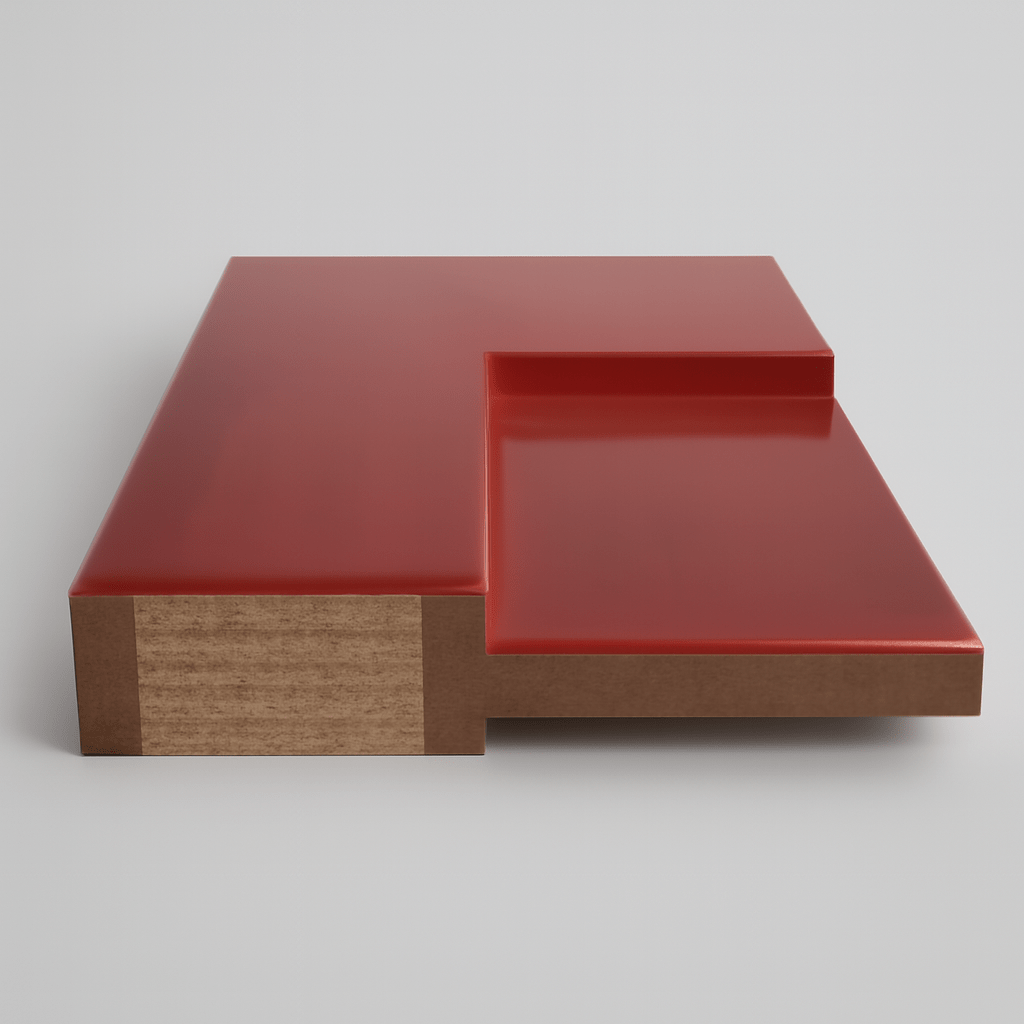

Thickness

The thickness of the door slab also plays a critical role. Residential interior doors in the U.S. are typically 1-3/8 inches thick, but commercial environments often require 1-3/4 inches to support larger hardware and resist abuse. Thicker doors not only feel more substantial but also offer improved sound attenuation and rigidity. A high-quality door, according to WDMA I.S.1A, should not exceed 1/4-inch warp over a 7-foot height. This dimensional stability is achieved by symmetrical construction, balanced veneer application, and proper core selection.

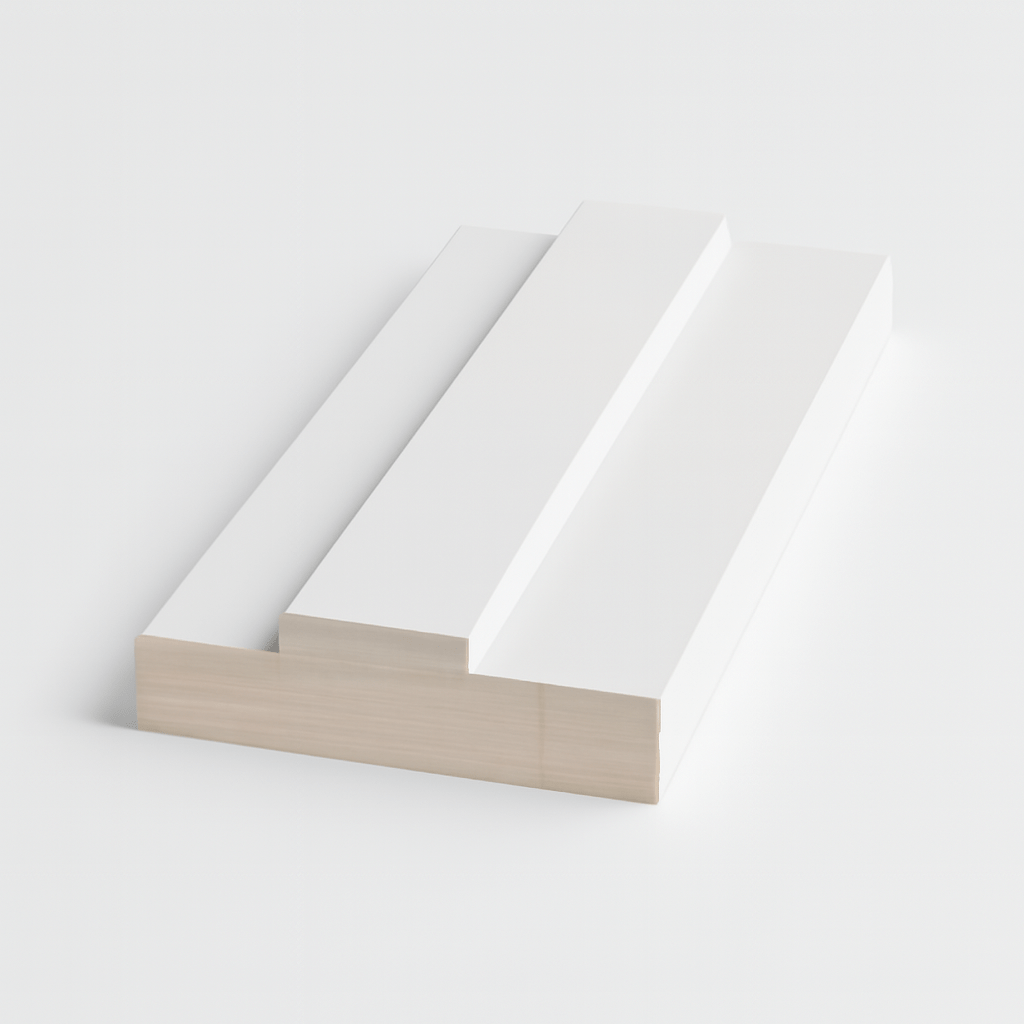

Frame&edge

Framing and edge construction should also be evaluated. High-traffic doors may include internal steel reinforcements at hinge and lock areas to prevent the core from compressing or splitting. Edge banding should be seamless and machine-applied with a consistent finish. Open-jointed edges, inconsistent gluing, or splintering at the corners are all red flags for poor manufacturing.

Also, check for compliance with the ANSI A208.1 standard if particleboard is used, ensuring it meets density and dimensional tolerance specifications. Doors made with substandard core material may pass initial visual inspection but will deteriorate rapidly under operational stress.

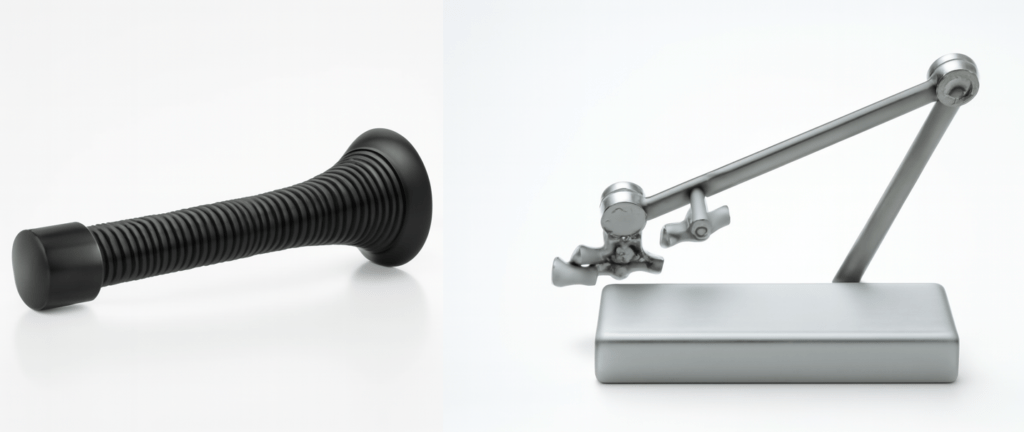

Hardware: The Components That Keep It Functional

After structure, hardware is the next most critical component. Even the best-built door will fail if its hinges, locks, or latches are weak, poorly aligned, or incompatible. ANSI/BHMA (Builders Hardware Manufacturers Association) provides a grading system for commercial and residential hardware: Grade 1 is the highest, recommended for heavy-use environments like schools and hospitals; Grade 2 is appropriate for light commercial or multi-family buildings; Grade 3 is limited to low-traffic residential interiors.

Start with the hinges. On a heavy, solid-core door, lightweight steel or zinc-plated hinges will wear out quickly or squeak under load. A quality hinge should be made of stainless steel or brass, machined with tight tolerances, and include ball bearings if used on heavier doors. Verify that the door slab has clean, factory-routed mortises for hinges to ensure proper alignment during installation. Sloppy, hand-chiseled hinge pockets on prehung units often cause operational issues down the line.

Next, examine the lockset. This includes the latch, strike, and handle or lever. Grade 1 locksets from brands like Schlage or Dormakaba are engineered to withstand over one million cycles of use. The latch bolt should be solid brass or steel, and deadbolts should include anti-saw pins. Be wary of plastic latch housings or unbranded hardware, which may feel functional but degrade quickly under load.

Door closers and stops are another often-overlooked category. ANSI/BHMA A156.4 specifies performance requirements for door closers, including opening force, backcheck strength, and adjustment features. Closers should be selected based on door weight and traffic volume. On solid-core doors, surface-mounted or concealed closers must be mounted into blocking or reinforced areas to prevent pullout over time.

Be sure to confirm that the hardware prep matches your selected components. Many commercial doors are factory-prepped for specific hardware series, including bore sizes, backset depth, and strike plate dimensions. Mismatched prep will result in improper fitting, rattling latches, or exposed voids.

A consistent finish across all hardware is also a sign of quality sourcing. For premium installations, coordinating finishes such as satin nickel, matte black, or polished chrome should match across hinges, levers, closers, and stops.

Finish: Where Durability Meets Aesthetics

Lastly, surface finish plays a significant role in both aesthetics and durability. A beautiful finish enhances perceived quality, while poor finishing accelerates degradation and leads to customer dissatisfaction. Finishes should be evaluated on several criteria: smoothness, adhesion, wear resistance, stain resistance, and UV stability.

Smoothness begins with substrate preparation. MDF is the preferred material for painted surfaces due to its flatness and lack of grain. On veneered doors, the veneer should be book-matched or slip-matched with minimal seams and consistent grain direction. Any inconsistencies in sanding, sealing, or priming will show up in the topcoat as orange peel, bubbling, or streaks.

Industrial coatings such as polyurethane, polyester, or UV-cured finishes offer the best performance in commercial environments. These coatings are typically applied in controlled environments using multi-stage processes that include sanding sealers, topcoats, and UV baking. ASTM D4060 is the standard test for abrasion resistance, commonly used with the Taber abrasion tester. A quality finish should withstand thousands of abrasion cycles without exposing substrate or changing gloss level.

Chemical and stain resistance is also important, particularly in healthcare, education, and hospitality settings. ASTM D6578 evaluates resistance to a range of substances, including permanent marker, wine, and household cleaners. In high-risk environments like children’s rooms or commercial restrooms, failure to resist staining can ruin aesthetics and lead to frequent replacement.

Gloss level is more than just a stylistic choice. Low-gloss or matte finishes hide fingerprints and dust better than high-gloss finishes. However, higher gloss may be specified in luxury settings for its reflective quality. Regardless of gloss, the surface should be even, without patchy reflections or inconsistent texture.

Doors exposed to natural light should also include UV inhibitors in the topcoat. Without them, surfaces may yellow, crack, or fade over time. Accelerated UV exposure tests—such as those described in WDMA TR-8—simulate years of sunlight in a matter of weeks. Premium products often specify a color ΔE shift of less than 3.5 after 1000 hours of UV exposure.

Moisture resistance is another factor. Even interior doors may face humidity in kitchens, bathrooms, or laundry rooms. Doors with sealed edges, water-resistant coatings, and laminated skins will resist swelling, peeling, and delamination. Inspect bottom rails carefully; unsealed or exposed MDF will absorb moisture from mopping or spills, leading to expansion and decay.

In addition, good finishes are consistent around the entire slab. Many low-cost products only finish the visible face, leaving top or bottom edges raw or lightly sealed. High-end manufacturers finish all six sides to reduce moisture migration and thermal imbalance, which can cause bowing or cupping.

To evaluate finish quality in practice, inspect a door under raking light and look for surface flaws. Run your hand gently across the surface—your fingers will feel imperfections that your eyes might miss. Doors with flawless finishes and durable topcoats not only look better but last significantly longer in the field.

Note: The standards mentioned above (ANSI/BHMA, ASTM, WDMA) are provided for reference only. They represent commonly accepted performance benchmarks within the building materials industry and are not mandatory certifications. Our products are designed and manufactured to align with these standards based on internal quality controls and industry best practices.

Conclusion

The quality of an interior door is determined by its structure, hardware, and finish—each playing a vital role in performance and longevity. A compromised element in any of these areas can significantly shorten the door’s lifespan and reliability. For construction professionals and procurement teams, it’s essential to evaluate doors not just by appearance or price but through a comprehensive assessment of materials, engineering, and quality standards. Choosing the right door at the outset is crucial to ensure durability, performance, and long-term value.