In today’s construction market, timelines are tight, budgets are under pressure, and any misstep in procurement can stall an entire project. While software can improve scheduling, true efficiency begins upstream—at the factory level.

So, what happens when advanced production technology meets lean construction principles—and how can builders turn that into a competitive edge?

Lean production in the building supply chain isn’t just about cutting costs—it’s about eliminating friction. By combining factory-direct access with lean methods like just-in-time delivery, flexible batching, and process standardization, builders gain tighter budget control, faster delivery timelines, and consistent product quality across every phase of construction.

Let’s break down exactly how UWG’s factory model translates lean production into real-world efficiency for builders—no matter the project scale.

UWG’s advanced factories combine lean production with full vertical integration, covering doors, cabinets, flooring, and mouldings. By using just-in-time scheduling, dynamic batching, and real-time factory feedback, UWG reduces waste, ensures consistent quality, and synchronizes deliveries with jobsite progress. This approach streamlines multi-category sourcing, minimizes delays, and helps builders control costs, improve efficiency, and execute projects with greater reliability.

Why Lean Construction Matters in Today’s Building Economy

Lean construction is not simply about minimizing waste—it’s about engineering reliable workflows in an increasingly volatile construction environment. Originating from the Toyota Production System, lean methods are now a proven framework for improving delivery, reducing friction, and stabilizing operations across the supply chain.

For builders, lean implementation translates to:

- Faster cycle times, thanks to synchronized procurement and just-in-time material staging

- Reduced rework, driven by consistent quality and standardized specs

- Seamless trade coordination, with materials arriving when and where they’re needed

- Enhanced project control, through transparent lead times and predictable cost structures

- Scalable sourcing, where repeatable product lines reduce variance and decision fatigue

Traditional construction procurement operates like a fragmented relay race—every vendor handoff adds risk. Lean construction eliminates those handoffs by designing a fully integrated value chain, from factory floor to jobsite install.

At its core, lean isn’t about doing more with less—it’s about doing exactly what’s needed, exactly when it’s needed, with as little deviation as possible.

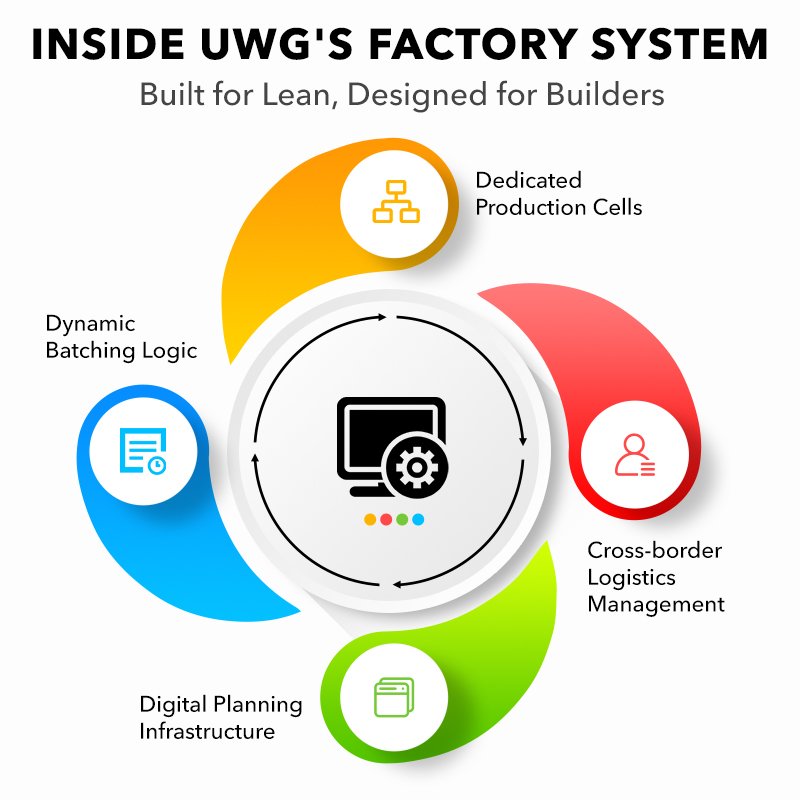

Inside UWG’s Factory System: Built for Lean, Designed for Builders

At UWG, lean thinking isn’t an add-on — it’s embedded in how our entire production ecosystem is built. We don’t just manufacture building products. We orchestrate synchronized, data-driven supply operations that align with the real-world needs of construction professionals.

Our advanced factory platform includes:

- Dedicated production cells for doors, cabinets, flooring, and mouldings — ensuring material consistency and minimizing changeover waste

- Dynamic batching logic, allowing us to pivot production volumes based on customer lead time and site-readiness

- Digital planning infrastructure, including ERP-integrated scheduling tools that track orders from engineering to outbound logistics

- Cross-border logistics management, where packaging, export prep, and customs coordination are handled in tandem — reducing shipping risk

Additionally, our factory-floor feedback loops allow real-time adjustments based on sample approvals, drawing changes, or customer input—giving builders agility without compromise.

🛠️ Key Differentiator: Unlike many suppliers that rely on third-party job shops, UWG owns and controls the full value chain—from raw material intake to container loading. This vertical integration eliminates uncertainty, accelerates execution, and supports lean workflows at scale.

Eliminating the 8 Wastes: How UWG Embeds Lean Thinking Into the Supply Chain

Lean production identifies eight categories of operational waste that reduce efficiency and erode profitability. In construction material supply chains, these forms of waste show up as missed deadlines, inventory bloat, and inconsistent quality—issues builders can’t afford.

Here’s how UWG tackles each of the eight with precision:

| Waste Type | In Construction Sourcing | How UWG Eliminates It |

|---|---|---|

| Overproduction | Excess stock driven by batch minimums | On-demand production calibrated to confirmed orders |

| Waiting | Idle crews waiting on late or partial deliveries | Just-in-time scheduling aligned with jobsite milestones |

| Transport | Multiple shipments across vendors increase freight & risk | Full-container, multi-category consolidation reduces moves |

| Extra Processing | Repalletizing, relabeling, or rechecking products | Pre-sorted, pre-finished packaging ready for install |

| Inventory | Overstocked or redundant site storage | Factory-side staging with synchronized shipping cycles |

| Motion | Jobsite staff re-handling misgrouped deliveries | Logistics-integrated packing plans by installation sequence |

| Defects | Rework from supplier inconsistencies | Tiered inspections including moisture, milling, and finish |

| Underutilized Talent | Builders forced to solve vendor errors | One-stop support reduces friction, frees team capacity |

Instead of solving problems after they appear, UWG’s lean framework is designed to engineer inefficiency out of the system from day one.

🔧 The Result? Less waiting, fewer callbacks, and more time spent building — not firefighting.

Unified Manufacturing: Doors, Cabinets, Flooring, and More — All Under One Roof

For most builders, sourcing across categories means juggling separate vendors for doors, cabinets, flooring, and trims — each with their own schedules, contacts, specs, and headaches.

UWG was purpose-built to solve this.

We manufacture and ship all major architectural categories from one integrated factory network:

- Interior and exterior doors — molded, flush, or shaker styles

- Modular and custom cabinetry — pre-assembled or RTA, in multiple finishes

- Laminate, SPC, and hardwood flooring — commercial- and residential-grade

- Decorative trims, crown mouldings, and stair systems — matched by species and finish

This unified production model delivers unmatched operational advantages:

- ✅ Visual and dimensional consistency across product lines

- ✅ Cross-category packaging, reducing jobsite sorting time

- ✅ Single-bill documentation, easing customs and accounting

- ✅ One point of contact, simplifying coordination

📦 Whether you’re ordering a full container or staging phased deliveries, UWG gives you a high-volume, multi-category pipeline—without the friction of multi-vendor sourcing.

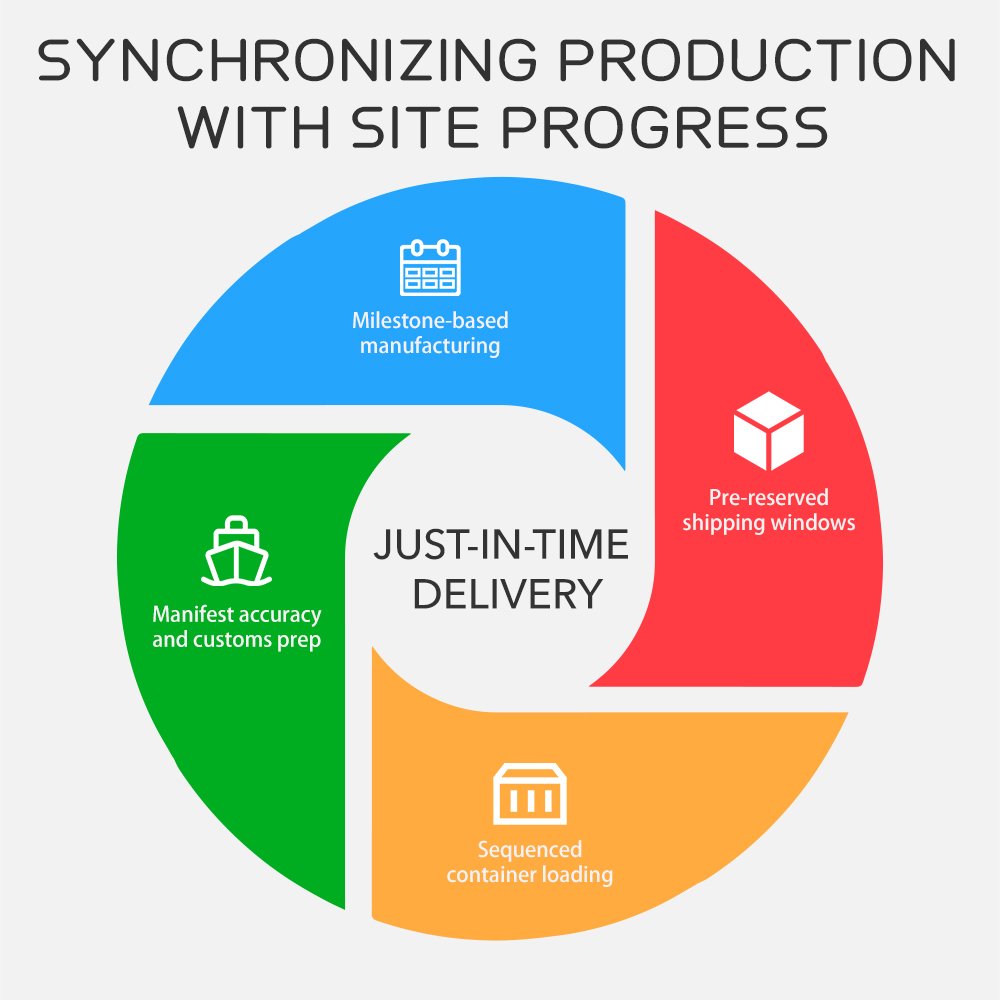

Just-in-Time Delivery: Synchronizing Production with Site Progress

For builders, timing isn’t a nice-to-have — it’s a necessity. Materials arriving too early create storage chaos and damage risk. Arriving too late? You miss critical install windows and delay the entire build.

That’s why UWG’s delivery model is engineered around project synchronization, not product dispatch.

Here’s how we align production with your jobsite schedule:

- 🗓️ Milestone-based manufacturing: Production kicks off based on your confirmed site timeline, not factory convenience.

- 📦 Pre-reserved shipping windows: We coordinate vessel booking and inland delivery before production finishes.

- 📑 Sequenced container loading: Goods are packed in reverse installation order — doors, cabinets, flooring — so the first item you need is the first out of the container.

- 🔄 Manifest accuracy and customs prep: Every shipment includes consolidated documentation, harmonized codes, and project-specific part labeling.

📍The result: fewer delays, cleaner sites, and maximum labor efficiency. Your crews build, not wait.

From Blueprint to Jobsite: A Seamless, End-to-End Execution Model

UWG doesn’t just make products. We engineer project execution from the moment your drawings hit our inbox.

Our integrated production model handles the complete lifecycle:

- Technical Blueprint Analysis – In-house engineers verify all details against U.S. framing and hardware specs

- Material Takeoff & Quoting – Clear, itemized pricing tied directly to site plans

- Sample Approval Cycle – Corner cuts, finish samples, product mockups – all delivered pre-order

- Batched Production – By category and install priority, ensuring minimal idle time onsite

- Global Freight + Local Handoff – Coordinated from our docks to yours, with customs-ready paperwork

- Installation Support (Optional) – If needed, we provide vetted U.S. teams trained on our product systems

🛠️ What does this mean for you? Total project visibility, reduced scope gaps, and fewer late-stage surprises. Builders stay focused on construction, not chasing down suppliers.

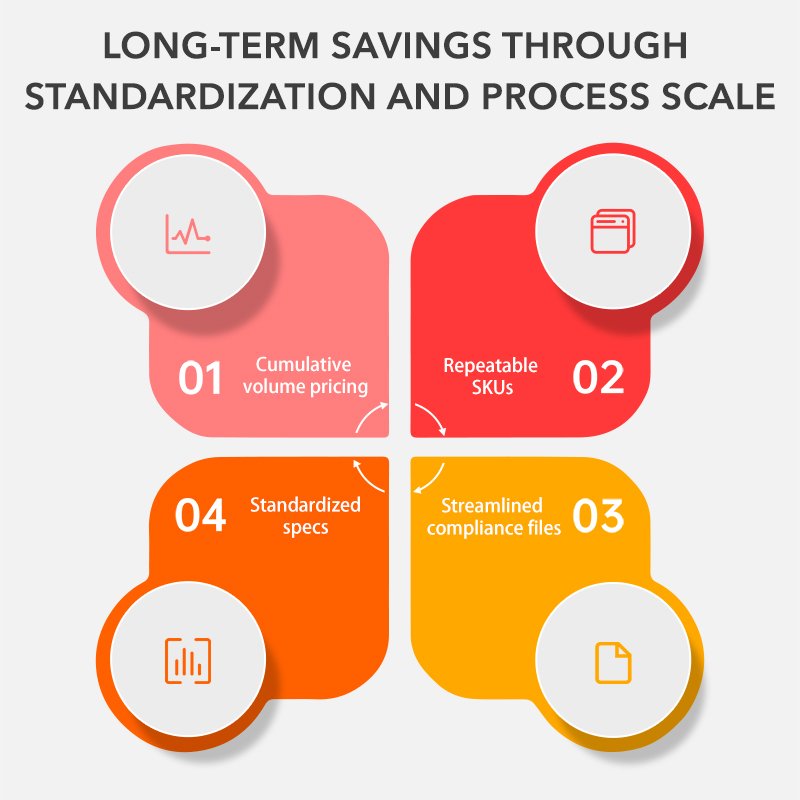

Long-Term Savings Through Standardization and Process Scale

Fast one-off purchases might patch a short-term gap — but they rarely build a profitable pipeline.

UWG supports builders in moving from transactional sourcing to a scalable procurement ecosystem:

- 📦 Cumulative volume pricing – Discounts applied across rolling orders, not just one shipment

- 📋 Repeatable SKUs – Simplify spec sheets, reduce on-site cutting, and speed up installs

- 📐 Standardized specs – Ensure approval consistency across projects and teams

- ✅ Streamlined compliance files – Easier handoffs to code inspectors and project managers

The more we work together, the less friction exists between you and your materials — and the more time your team spends building instead of troubleshooting procurement.

Summary: Lean Manufacturing Is Not a Trend — It’s a Competitive Edge

In a construction market where timing, cost control, and delivery reliability are make-or-break, UWG’s lean-driven model offers more than just lower prices.

We provide:

- 🔄 Fully synchronized production across multiple material categories

- 📦 Container-level optimization tailored to your installation sequence

- ✅ Quality consistency trusted by global brands and contractors alike

- 📈 Long-term scalability through process standardization and digital logistics

So the real question isn’t “does lean work?” It’s this: Are you ready to build smarter, faster, and more profitably — with UWG?