Choosing the right casing or trim for doors and windows can be challenging—especially when balancing durability, appearance, and cost. Many builders, wholesalers, and homeowners find themselves comparing solid wood, MDF, and finger joint options. So, is finger joint casing a good choice? In most cases, yes—it’s one of the most practical and efficient materials for painted interior trims.

Finger joint casing has gained popularity for its affordability, sustainability, and smooth, consistent finish. Made from smaller wood sections joined with precision finger cuts, it offers the strength and stability of solid wood with less waste and lower cost. Still, like any material, it has both advantages and limitations. Let’s take a closer look at what makes finger joint casing worth considering—and when it might not be the ideal fit for your next project.

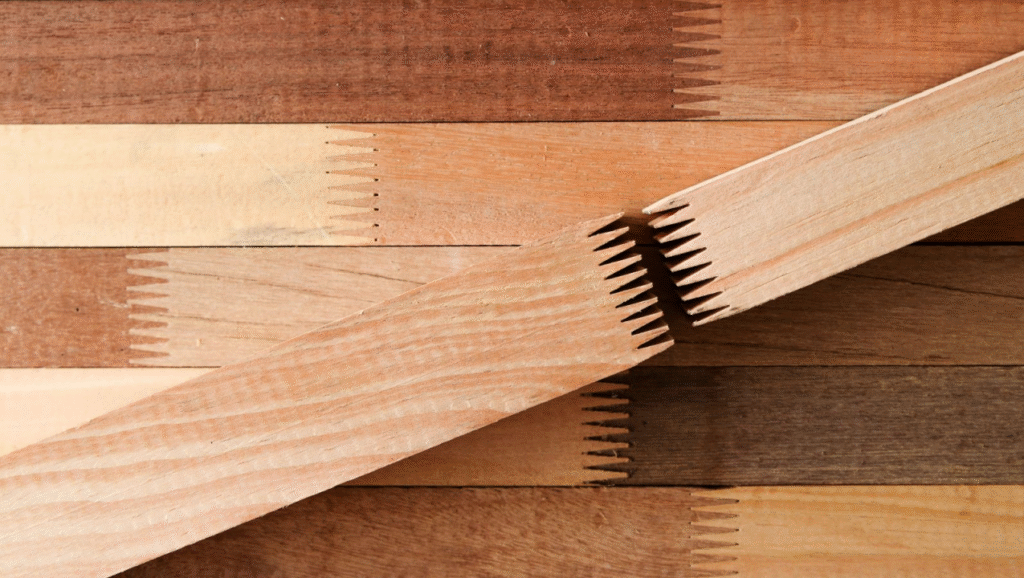

What Is Finger Joint Casing?

Finger joint casing is made by gluing together short pieces of wood that have been precisely cut into interlocking “fingers.” These joints create a strong bond under pressure, forming long, straight, and stable boards ideal for trim applications such as baseboards, window casings, and door frames.

Typically crafted from kiln-dried pine or other softwoods, finger joint mouldings are known for their excellent uniformity and smooth surface. They are most often used for painted finishes rather than natural stains, since the joint lines would otherwise remain visible. Because they utilize smaller wood sections that would otherwise go to waste, finger joint casings offer both cost efficiency and environmental sustainability. Many come pre-primed, ready for quick installation and painting—making them a smart, practical choice for modern interior project.

Advantages of Finger Joint Casing

There are several reasons why finger joint casing has become a preferred choice in modern interior design and construction. Beyond affordability, it offers a balance of strength, sustainability, and aesthetics that make it suitable for a wide range of residential and commercial applications.

Cost-Effective Without Compromising Quality: Finger joint casing delivers the appearance and performance of solid wood at a fraction of the cost. Because it’s made from smaller pieces of wood, production is more resource-efficient, which translates to lower prices for builders and homeowners. This makes it an ideal option for large-scale housing projects, renovations, or anyone seeking high-quality trim work on a budget.

Environmentally Friendly Choice: Sustainability is a major advantage. The finger joint manufacturing process repurposes short wood offcuts that would otherwise be discarded, reducing overall material waste. By maximizing the use of harvested timber, this process supports responsible forestry practices and minimizes the environmental footprint of production.

Superior Dimensional Stability: One of the biggest challenges with solid wood trims is warping or twisting over time—especially with changes in temperature and humidity. Finger joint casing minimizes these issues because the alternating grain directions of each joint balance out internal stresses. The result is a straighter, more stable product that maintains its shape long after installation.

Smooth and Consistent Painted Finish: Unlike solid wood, which can have knots or irregular grain, finger joint casing provides a uniform surface that’s ideal for painting. Most products are pre-primed at the factory, saving time during installation. Once coated with paint, the joints blend seamlessly, giving a clean, professional finish. This consistency makes it a top choice for contemporary and minimalist interior designs where smooth lines and flawless surfaces are key.

Lightweight and Easy to Work With: Finger joint casing is not only durable but also remarkably user-friendly. Its light weight makes it easier to handle and install, even for single-person jobs. It cuts cleanly with standard woodworking tools and holds nails or adhesives securely. For contractors, this means faster installation times and less material waste; for DIY homeowners, it means a straightforward, frustration-free project.

Comparison of Common Casing Materials

When comparing finger jointed pine to other common materials like solid pine, MDF, and poplar, each comes with its own strengths and limitations.

Finger jointed pine is a cost-effective and stable choice. It is excellent for painted applications and resists warping better than solid wood. However, it’s not ideal for staining because the joints may be visible if left unpainted.

Solid pine offers a natural wood look and can be stained, which is great for projects aiming for a rustic or high-end wood appearance. That said, solid pine tends to cost more and is more prone to warping or splitting, especially in areas with high humidity or temperature changes.

MDF (medium-density fiberboard) is an economical alternative that provides a smooth surface, making it easy to paint. It’s widely used in residential and commercial interiors. However, MDF lacks the durability of real wood and can be easily damaged by moisture or impact.

Overall, finger jointed casing finds a comfortable middle ground in terms of price, performance, and versatility—especially when painting is the final finish.

How to Choose the Right Casing

For high-traffic areas, it’s best to choose a strong, stable material like finger jointed pine. If budget is a concern, both MDF and finger joint casing are practical options that still deliver a clean, finished look.

If your project involves painting, finger joint and MDF are ideal. For projects requiring a natural wood finish, solid pine is a better choice.

In humid environments such as kitchens, bathrooms, or coastal areas, finger joint casing made from primed pine performs better than MDF, which tends to swell and deteriorate over time.

For bulk purchases or standardized production needs, finger joint boards are readily available in consistent, long lengths. This makes them easier to stock, transport, and install on a larger scale.

Finger joint casing also provides a neat, modern appearance once painted. However, if the final look demands visible wood grain or rich stains, solid pine would be the better recommendation.

Summary

Finger joint casing delivers an exceptional balance of price, performance, and practicality—making it one of the most popular choices for modern construction and interior trim projects. Its stability, smooth painted finish, and cost efficiency make it ideal for both residential and commercial applications, especially where consistent quality and fast installation matter most.

For painted interiors, finger joint casing offers the refined appearance of solid wood without the high material cost or risk of warping. It’s a smart, sustainable solution for builders, wholesalers, and designers seeking reliable trim products in volume.

As a professional moulding and casing manufacturer, we offer a wide range of finger joint casings in various sizes, profiles, and finishes to meet different project needs. Whether you’re working on large-scale developments or custom interior upgrades, our team can help you select the right specifications and provide tailored production support.

Let’s explore how our quality casing solutions can enhance your next build or renovation.