Lumber shortages and inconsistent structural integrity frustrate builders daily. Traditional timber warps, cracks, and varies in quality. Fortunately, there’s a smarter solution. Laminated Veneer Lumber (LVL) offers high strength, consistency, and reliability—making it a favorite in modern construction.

Laminated Veneer Lumber (LVL) is an engineered wood product crafted by bonding thin wood veneers in parallel grain alignment using durable adhesives. This design concentrates strength along the grain, yielding exceptional tensile/compressive strength, stability, and uniformity—unlike natural lumber, which may have defects. Widely used in construction for beams, headers, and rim boards, LVL supports heavy loads over long spans with minimal warping, enabling open floor plans and robust structural connections. Its engineered consistency enhances reliability, while efficient wood use and resistance to decay promote sustainability, making it a cost-effective, eco-friendly alternative to traditional timber.

Let’s explore LVL in depth—from what it is and how it’s made to how it performs on-site and why it’s becoming a go-to choice in both commercial and residential builds.

What is an LVL?

Laminated Veneer Lumber (LVL) is a type of engineered wood product designed for structural applications. Unlike solid sawn timber, LVL is made from thin wood veneers—typically of softwood—glued together under heat and pressure. All the grain runs in the same direction, resulting in a strong, stable product that resists warping, shrinking, and splitting. It’s widely used in residential and commercial construction where strength and uniformity are critical.

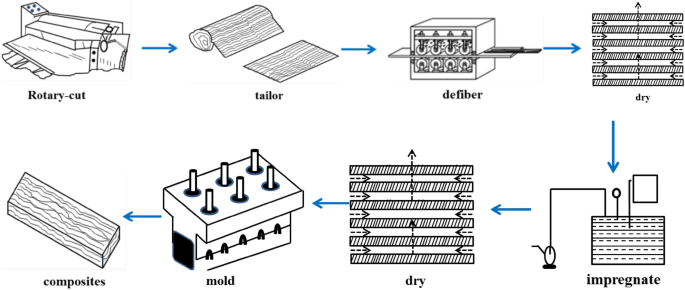

How is LVL Made?

The manufacturing process of LVL starts with peeled veneers—thin sheets sliced from logs using a rotary lathe. These veneers are dried, coated with waterproof adhesives, and stacked in layers with the grain running parallel. They are then hot-pressed under intense heat and pressure to bond the layers together into a solid billet. Once cured, the billets are cut to standard sizes and sealed. This process ensures minimal material waste and consistent structural performance.

What are the Advantages and Disadvantages of Laminated Veneer Lumber?

Advantages:

- High strength-to-weight ratio for heavy-duty load applications

- Longer lengths available (often up to 60 feet)

- More uniform and predictable than sawn lumber

- Resistant to twisting, bowing, and shrinking

Disadvantages:

- Vulnerable to moisture if unsealed, leading to swelling or delamination

- More expensive than standard lumber

- Edge sealing required in exposed environments

- Can’t be notched or cut without engineering approval

Is LVL Stronger Than Wood?

Yes, LVL is typically stronger and stiffer than traditional lumber of the same dimensions. Because it is engineered, it eliminates natural inconsistencies like knots or grain deviation found in sawn timber. LVL can carry greater loads over longer spans without sagging, making it ideal for headers, beams, and floor systems. For structural work, especially where precision matters, LVL often outperforms standard timber.

How Strong is Laminated Veneer Lumber?

The strength of LVL can vary depending on the manufacturer and intended use, but it typically boasts:

- Bending strength (Fb): ~2,800 to 3,000 psi

- Modulus of Elasticity (E): ~1.9 to 2.0 million psi

- Shear strength: higher than that of dimensional lumber This strength allows LVL to support longer spans in floors, roofs, and multi-story walls without intermediate supports.

What is LVL Wood Used For?

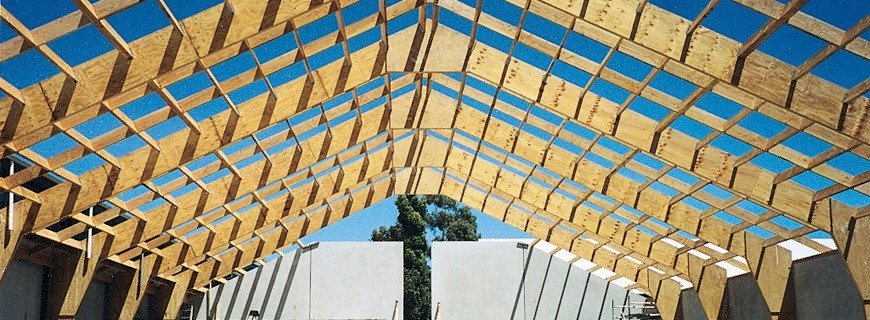

LVL can be used anywhere dimensional lumber is used—especially where strength is critical. Common applications include:

- Beams and headers over doors and windows

- Floor joists and rim boards

- Tall wall studs in high-load areas

- Roof beams in long-span applications

- Cantilevered decks and mezzanines Because of its performance, LVL is also ideal for retrofitting and structural upgrades.

Why is LVL Used in Construction?

LVL is prized in construction for its:

- High load-bearing capacity

- Dimensional stability (resists warping and shrinking)

- Availability in long lengths, reducing joints and weak points

- Predictable engineering properties, simplifying structural calculations Builders often use LVL for load-bearing beams, tall walls, and floor headers, especially in environments where code compliance and performance matter.

How to Use LVL in Home Renovation?

In renovation projects, LVL shines when you need to remove a load-bearing wall, create an open-concept layout, or reinforce old framing. Here’s how to use it effectively:

- Replace undersized beams with LVL to carry added loads.

- Use LVL for headers over widened doorways and windows.

- LVL is perfect for spanning large kitchen or living areas without columns. Just make sure to check spans with an engineer and install with the right hangers and supports.

Professional Advice: Builder Best Practices for Using LVL

Installation Tips

- Store LVL flat and off the ground, in a covered, dry area to prevent moisture absorption.

- Seal all cut ends and exposed surfaces with a waterproof edge sealer to prevent swelling and delamination.

- Use corrosion-resistant fasteners and always pre-drill when necessary—LVL’s density can damage tools or split unsealed edges.

- Avoid notching, drilling, or modifying LVL without structural approval—doing so can compromise integrity.

- For exterior or damp conditions, request pressure-treated LVL and seal thoroughly.

Structural & Compliance Advice

- Always check your local building code for LVL requirements (spans, bearing length, fire ratings).

- Use metal hangers and brackets designed for engineered wood—not standard lumber hardware.

- Ensure the grain direction is correct during installation—LVL is directional and performs best along the grain.

- When spanning long distances or replacing load-bearing walls, always consult a structural engineer for sizing and support design.

Field Wisdom from Builders

- Wet LVL is not a deal-breaker—but allow it to fully dry before installation and re-seal if needed.

- Blades and fasteners dull faster—plan for tool wear if cutting multiple LVL pieces onsite.

- When unsure, overbuild and reinforce—LVL’s load rating is high, but poor fastening ruins performance.

Summary

Laminated Veneer Lumber offers strength, predictability, and flexibility in construction and renovation. Whether you’re framing a new structure or reinforcing an old one, LVL is a smart, engineered solution. Have you worked with LVL? Drop your insights or questions below—we’re all building better together.