Manufacturing Network

A resilient manufacturing matrix combining self-owned assets with global strategic synergy to ensure uninterrupted supply and dynamic scalability.

Multi-Regional Architecture · Global Synergy for Supply Stability

UWG has established an interconnected manufacturing network with self-owned bases as the core, supported by deep-linked partner facilities.

This structure ensures multi-site production capabilities for every product category, effectively eliminating "single-point failure" risks and providing an absolute safety net for your supply chain.

Fujian Production Base

Vertical Integration & Raw Material Hub

Key Products: Door Frames, Mouldings, Wall Panels, Molded Doors, and high-spec Fire-rated Doors.

Zhejiang Production Base

Advanced R&D & Precision Manufacturing

Key Products: Shaker, Solid Wood, and Louvered Doors; Professional-grade Custom Cabinetry.

Vietnam Material Production Base

Strategic Resource & Processing Base

Key Products: Lumber Milling, high-strength LVL, Primed Door Frames, and S4S Boards.

Vietnam Production Base

North American Delivery & Export Center

Key Products: American-style Kitchen Cabinets and Standardized Interior Doors.

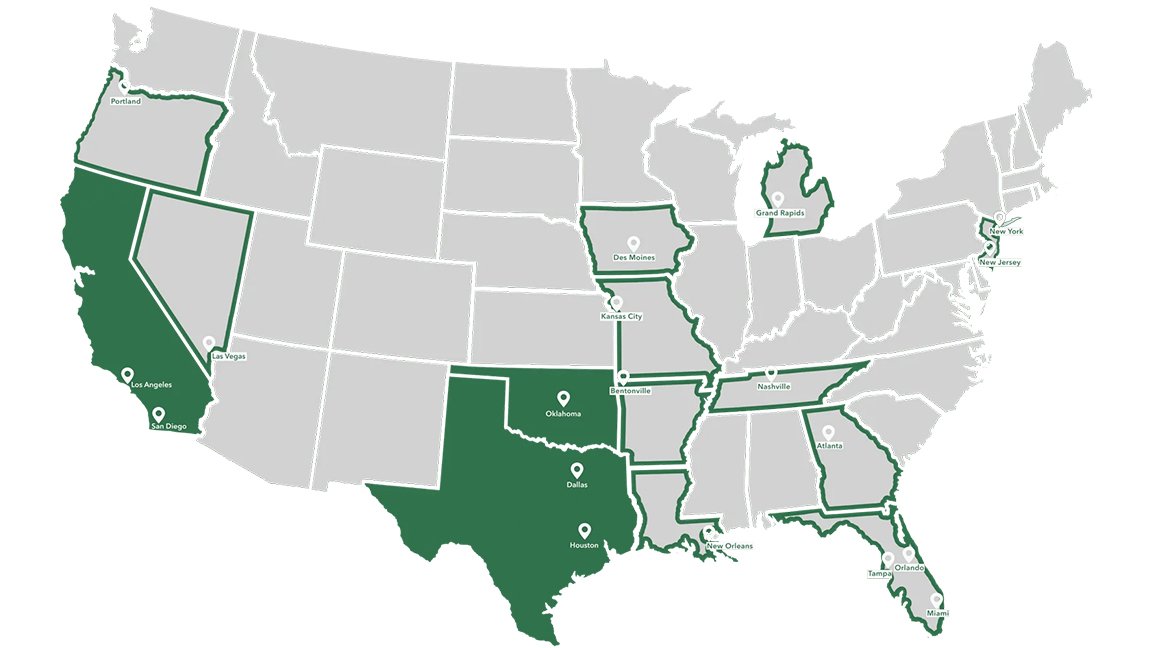

U.S. Local Support

Agility, Inventory & Project Service

The core hub for large-scale delivery and urgent replenishment.

Multi-Point Resilience: Eliminating Single-Point Failure

We recognize the critical importance of continuous supply. Through our cross-regional capacity layout, UWG ensures that your core categories have redundant backups across different production regions

Cross-Regional Redundancy

Our network spans China, Southeast Asia, and the United States. Should one region face trade fluctuations, logistics bottlenecks, or force majeure, other regions can seamlessly take over orders to ensure your projects never stop.

Quality Synchronization

All network members (including deep-linked partners) execute unified UWG quality benchmarks and SOPs, ensuring consistent excellence regardless of the production origin.

Dynamic Scalability: How We Scale Your Success

Supporting your growth through proven operational mechanisms and resource fluidity.

Elastic Production Scheduling

Our network utilizes a unified coordination system. During demand surges, we redistribute idle capacity across factories in real-time, spreading the pressure across the entire network to achieve rapid scaling.

Unified Tooling & Standardization

We pre-sync standardized tooling and process manuals across the manufacturing network. This allows your SKUs to achieve "plug-and-play" production shifts at any node without re-sampling, drastically shortening scaling cycles.

Strategic Raw Material Buffer

Leveraging our material bases in Fujian and Vietnam, we maintain reserves far exceeding the needs of a single factory. These "mobile resources" can be quickly funneled to nodes requiring rapid scaling, ensuring your large-scale needs are met even during global timber shortages.

Explore More

Our Factories

Quality Control

Audits & Certifications

Products

Projects