Our Factories

UWG owns and directly operates four production bases across China and Vietnam. Our 100% ownership ensures absolute command over the entire process, from raw material sourcing to final inspection.

This guarantees competitive pricing, controlled lead times, and unshakeable quality for every client.

Owned Assets. Direct Control. Absolute Certainty.

Unmatched Cost Leadership:

Eliminating middleman markups. By controlling the entire process from raw timber to finished product, we lock in long-term price stability for our partners.

Absolute Production Priority :

As the asset owners, we have total authority over scheduling. Your project deadlines are never compromised by third-party subcontracting delays.

Integrated Quality DNA :

Direct oversight means our standards are embedded in every machine and every workstation. We deliver consistent excellence across all regions and batches.

Manufacturing at Scale

Resource backing for total supply chain certainty. Leveraging our extensive self-owned resources, UWG provides efficient, consistent, and reliable delivery assurance for projects of any scale.

32+ Acres Strategic Footprint

Ample self-owned space for integrated production and large-scale logistics.

900+ Professionals Managed Team

Ensuring UWG’s quality standards are executed at every single workstation.

1,000+ Containers Annual Capacity

Proven annual capacity to support national retail and major building projects.

10,000+ m³ Material Security

Massive on-site stock to insulate your projects from market fluctuations.

Our Global Production Matrix

Four Self-Owned Bases: The Perfect Synergy of Resources and Regional Advantages.

Fujian Production Base

Located in Youxi County, Fujian, China.

Vertical Integration Center & Core Raw Material Hub

This facility serves as the “Energy Source” for our entire supply chain. Beyond its diverse production lines, it centralizes raw material processing and vertical integration, ensuring cost stability and material consistency across all sites.

Product Scope:

Millwork & Doors:

Door Frames, Mouldings, Wall Panels, and Molded Doors

Safety Solutions:

High-spec Fire-rated Doors.

Finishing Excellence:

Comprehensive options from Primed to full Standard Paint.

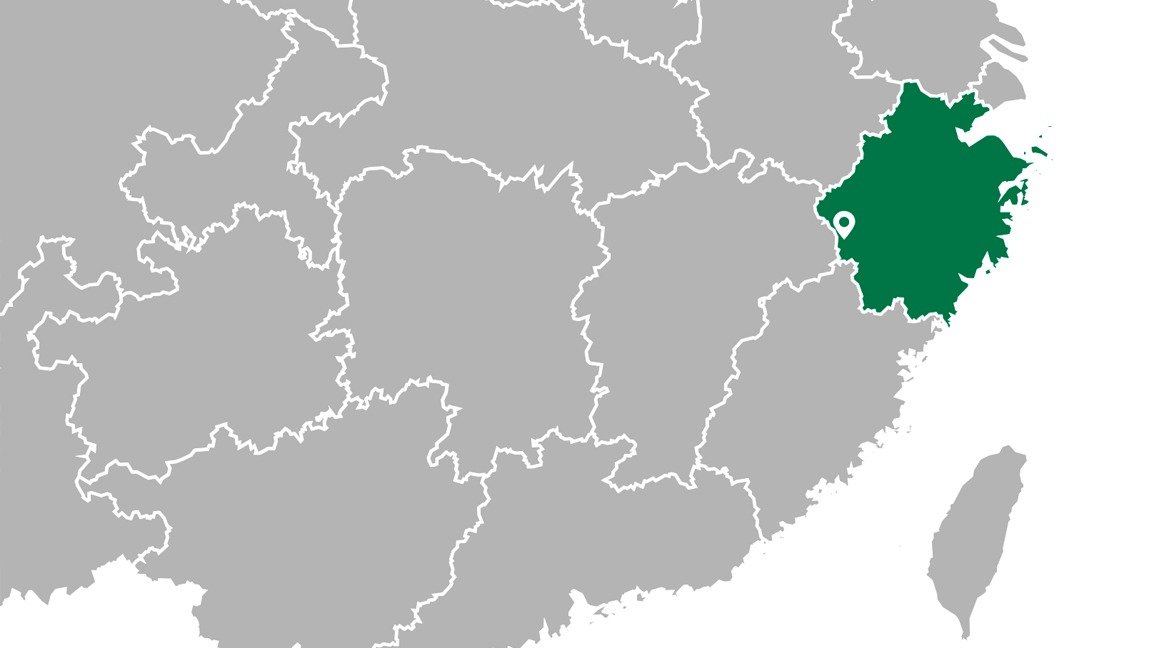

Zhejiang Production Base

Located in Jiangshan City, Zhejiang, China.

Advanced R&D & Precision Manufacturing Center

Dedicated to technical excellence in complex surface treatments and high-end customized products. This base leads the group’s high-precision production and management for cabinetry and premium interior doors.

Product Scope:

Premium Interior Doors:

Shaker, Solid Wood, Folding, French, and Louvered Doors.

Cabinetry Solutions:

Professional-grade Whole-home Custom Cabinetry.

High-End Finishes:

Mastery in High-gloss Enamel and UV-cured Lacquer coatings.

Vietnam Material Production Base

Located in Bắc Kạn, Vietnam.

Southeast Asian Strategic Resource & Primary Processing Base

Leveraging local and imported timber, this site establishes a “Resource Safety Net” for the group in Southeast Asia, providing a large-scale supply of foundational construction materials.

Product Scope:

Structural & Raw Materials:

Lumber Milling and high-strength LVL (Laminated Veneer Lumber) production.

Primed Millwork:

Export-ready Primed Door Frames and S4S Boards.

Architectural Details:

Standardized Decorative Mouldings.

Vietnam Production Base

Located in Phú Thọ, Vietnam.

North American Delivery & Standard Exportation Center

Operated through dispatched management and technical teams from headquarters, this facility ensures “Management Penetration” identical to our China bases, serving as a core hub for mitigating trade risks and ensuring supply resilience.

Product Scope:

US-Standard Cabinetry:

Specialized American-style Kitchen Cabinets.

Interior Door Systems:

Standardized Interior Doors fully aligned with North American builder and retail benchmarks.

Quality Assurance:

Integrated quality control synchronized with global UWG standards.

Explore More

Manufacturing Network

Quality Control

Audits & Certifications

Products

Projects