Quality Control

Quality by System, Not by Chance

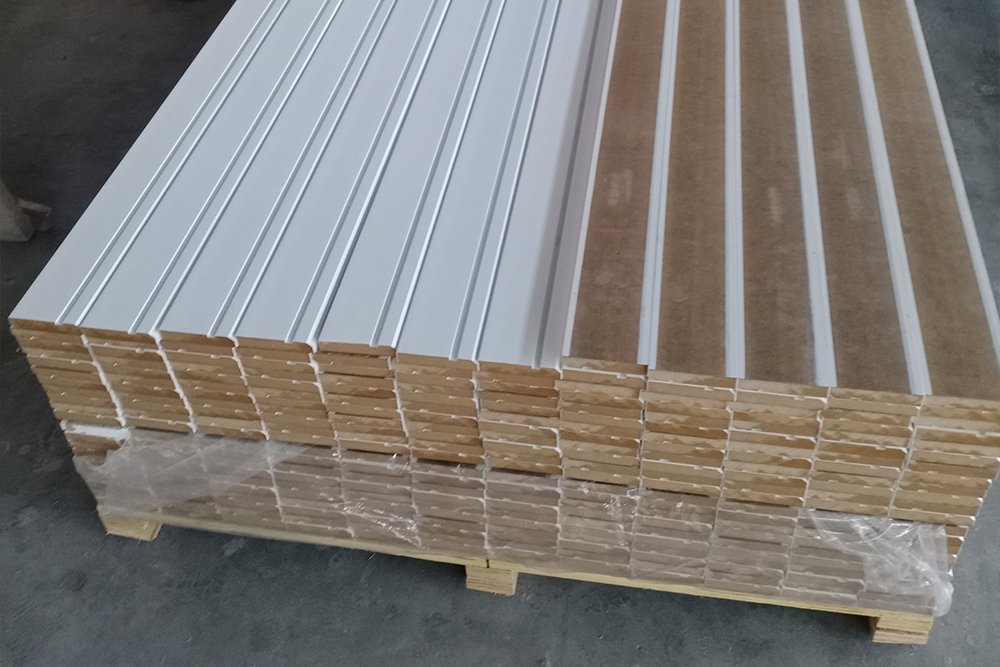

At UWG, quality management is a comprehensive engineering system involving every team member and every process. Through our highly standardized framework, we ensure that every product maintains exceptional consistency across different bases and production batches.

Integrated Quality Systems: Standards into Habits

Standardized SOPs:

We deconstruct complex manufacturing into quantified operational nodes. Every worker must pass station-specific evaluations, ensuring precision remains consistent regardless of personnel changes.

Embedded KCPs (Key Control Points):

Strategic control points are integrated into every stage of the production line. By adopting a "front-loaded" control strategy, we ensure defects are intercepted the moment they occur rather than moving downstream.

Three-Tier Inspection Matrix

Defining Accountability, Building a Cross-Defense Network

Tier 1: Workstation Self-Check

Core Principle: Empowering workers with the "Right to Stop." Every station is equipped with custom gauges. Workers are responsible for inspecting upstream input and ensuring downstream output. Our fundamental rule: "Do not accept, do not manufacture, and do not circulate defects."

Tier 2: IPQC Process Audit

Core Principle: Real-time dynamic monitoring. Our dedicated patrol team performs random sampling every 2 hours, monitoring equipment parameters (e.g., heat-press temperature, lacquer viscosity) and core dimensions. Utilizing Statistical Process Control (SPC), we preemptively intervene if trends deviate.

Tier 3: Final Quality Control

Core Principle: Thinking like the customer. Executed by an independent QA team, this stage strictly enforces acceptance standards covering aesthetic flaws, structural stability, hardware fluidity, and packaging durability, ensuring only premium products leave the facility.

The UWG Quality Journey: Step-by-Step

Step 1: IQC (Incoming Quality Control)

Rigorous sourcing and testing to ensure 100% material compliance.

Step 2: First-Piece Inspection

Establishing the benchmark to eliminate risks before mass production.

Step 3: IPQC (In-Process Quality Control)

Dynamic monitoring to ensure manufacturing precision and stability.

Step 4: Laboratory Performance Testing

Physical testing to simulate extreme real-world environments.

Step 5: FQC & OQC (Final & Outgoing Check)

Final acceptance, guarding the last gate of quality.

Accountability & Traceability

Transparent Quality, Traceable Responsibility

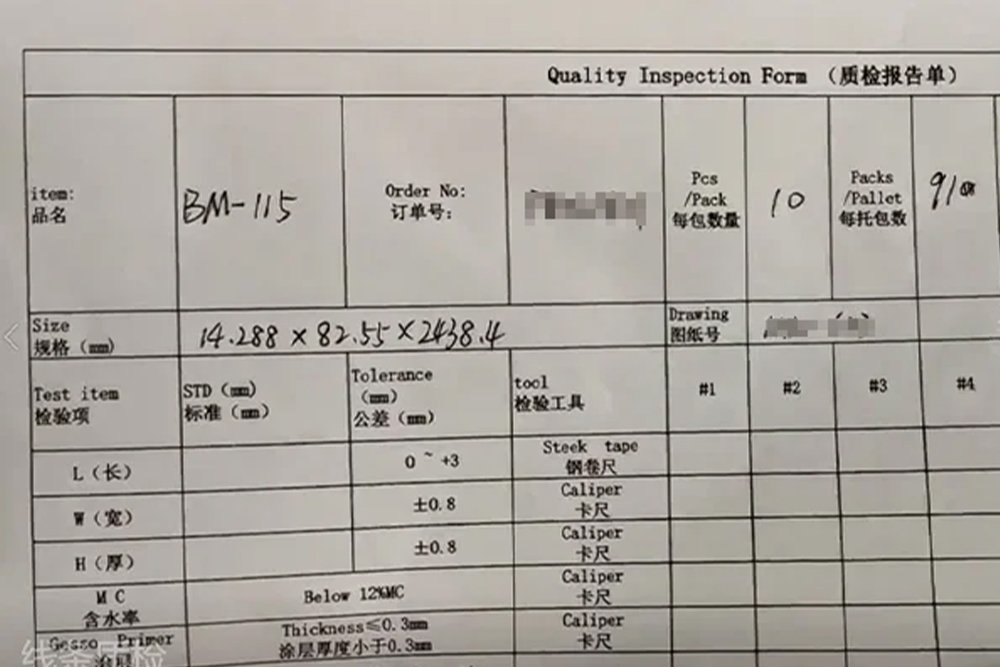

Real-time Documentation

Every order is backed by a dedicated digital quality file, documenting every detail of the fulfillment process.

Full Traceability

Utilizing unique batch codes, we enable bi-directional tracking—from raw material origins to specific machinery—creating a fully closed-loop system.

Standard of Accountability

Quality records are a vehicle for responsibility. We ensure every participant is accountable for the final result, driving continuous process optimization.

Explore More

Our Factories

Manufacturing Network

Audits & Certifications

Products

Projects