You’re preparing a multi-unit housing development, and you need interior mouldings that are not only cost-effective, but also durable, smooth to paint, and consistent in quality. Your supplier offers several options—MDF, HDF, and solid wood. But which one is the most suitable for your application?

The answer depends on your priorities. If you’re looking for affordability and smooth finishing, MDF is often the top choice. For higher density, better moisture resistance, and improved durability in high-traffic areas, HDF performs better. And if your project demands premium aesthetics, natural grain, or custom staining, solid wood remains unmatched. In the sections below, we’ll break down the characteristics, advantages, and ideal use cases for each material—so you can make the right decision for your next project.

Comparing Core Materials: MDF, HDF, and Solid Wood

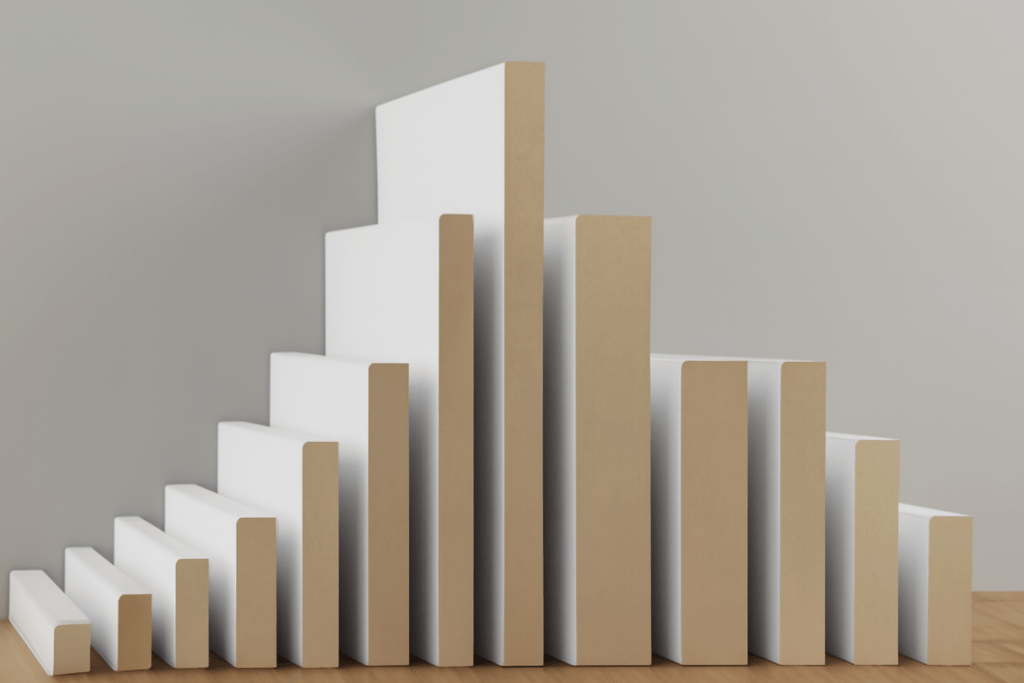

Choosing the right core material for mouldings depends on a mix of performance needs, aesthetic expectations, cost control, and site conditions. Below is a detailed breakdown of how MDF, HDF, and solid wood perform when used for interior trim and decorative moulding applications.

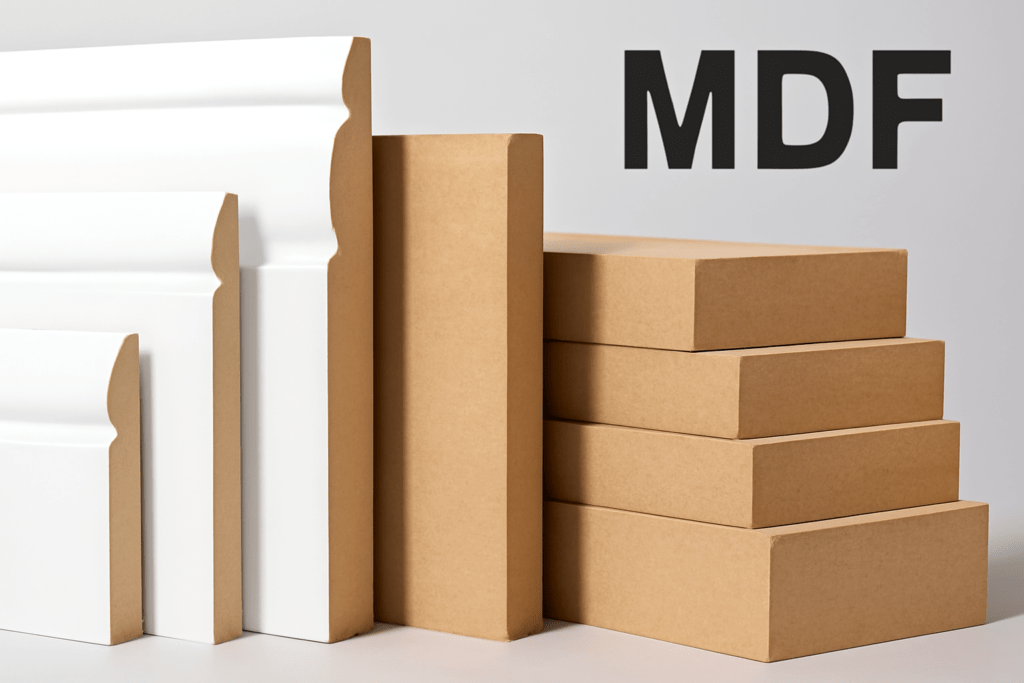

MDF (Medium-Density Fiberboard)

MDF is engineered from fine wood fibers and synthetic resins, pressed under heat to form dense, smooth panels. It is one of the most widely used materials for paint-grade mouldings in the North American market.

Why it works well for mouldings:

- Provides a smooth, uniform surface ideal for painting, lacquering, or foil wrapping.

- Excellent workability—easy to cut, mill, and profile with consistent results.

- Free from natural wood defects like knots, grain, or pitch pockets.

- High dimensional stability under dry, indoor conditions.

Limitations:

- Absorbs moisture easily if not properly sealed, leading to swelling or edge damage.

- Lower density than HDF makes it more vulnerable to dents and chipping.

- Not suitable for stain-grade or natural wood grain applications.

Recommendation:

Use MDF for large-scale interior trim projects where painted finishes, cost efficiency, and consistent detailing are the main priorities. It’s especially suitable for residential baseboards, crown mouldings, door casings, and window trim in dry environments.

HDF (High-Density Fiberboard)

HDF is manufactured similarly to MDF but with much finer fibers and higher compression. This results in a board that is denser, stronger, and more resistant to wear.

Why it works well for mouldings:

- Higher density improves resistance to surface damage—great for high-traffic spaces.

- Allows sharper, cleaner profiles for detailed or decorative moulding designs.

- Superior surface quality—ideal for premium paint finishes and wrapped mouldings.

- More dimensionally stable than MDF in variable humidity environments.

Limitations:

- Heavier than MDF, which can increase handling and installation effort.

- More expensive, both in raw material and tooling wear.

- Not designed for stain or clear-coat applications due to lack of wood grain.

Recommendation:

Choose HDF for mouldings used in commercial spaces, rental properties, or moisture-prone zones like entryways, basements, or utility rooms. It’s ideal for projects that demand impact resistance, longevity, and premium finishes.

Solid Wood

Solid wood mouldings are cut directly from natural timber such as pine, poplar, or oak. They are valued for their organic grain and ability to accept a wide range of finishes.

Why it works well for mouldings:

- Offers authentic wood grain, perfect for stain-grade or clear-coated trim.

- Easy to repair, refinish, and modify post-installation.

- High structural strength with a premium visual appeal.

- Perceived as a high-end option in both residential and commercial projects.

Limitations:

- Naturally reactive to changes in humidity—can shrink, swell, or warp over time.

- Material inconsistencies (color variation, knots, etc.) require careful selection.

- Highest cost per linear foot, with more waste due to grading requirements.

Recommendation:

Solid wood is the best choice for high-end homes, restoration projects, or custom millwork, especially where natural finishes are part of the design intent. However, it’s less suited for tight-budget, large-scale production unless specific performance or visual features are required.

Summary Table

| Material | Best For | Avoid In |

|---|---|---|

| MDF | Painted mouldings in dry, controlled interiors | Bathrooms, basements, or high-impact areas |

| HDF | High-traffic zones, premium painted profiles | Projects with strict weight/cost limits |

| Solid Wood | Custom or stain-grade trim with natural look | Budget builds or humid environments |

How Does Material Choice Impact Installation Time and Labor Cost?

In large-scale building projects, labor cost and installation efficiency can be just as important as material price. When selecting moulding materials, it’s essential to consider not only the cost per linear foot, but also how easily the material can be handled, cut, nailed, and finished on-site.

MDF is widely regarded as the most installer-friendly material. Its moderate weight makes it easy to carry and position, especially when working with long baseboards or crown mouldings. The consistent density and smooth surface allow for clean cuts with minimal splintering, and fastening with brad nails or finish nails is quick and secure. Most MDF profiles come primed and ready to paint, reducing finishing time. For residential developments or high-volume trim installations, MDF helps crews maintain a steady pace and minimize errors.

HDF, while denser and heavier than MDF, still offers predictable machining behavior. It is preferred in commercial jobs where a harder surface is needed, but installers should be aware that the increased density may cause faster wear on blades and tools, and the material requires slightly more effort during cutting and fastening. However, it holds profiles well and produces crisp edges, which means less sanding and cleanup during finishing.

Solid wood, on the other hand, demands more skill and care during installation. Natural wood can vary in straightness, grain direction, and hardness. Installers may need to sort and trim pieces manually, pre-drill holes to avoid splitting, and spend more time matching grain or color if pieces will be stained. Warping and cupping—especially in wider profiles—can also slow down progress. For this reason, labor costs for solid wood installations tend to be 15–25% higher on average compared to engineered alternatives.

In summary:

- Choose MDF when speed, ease of handling, and consistency matter most—ideal for painted interior trim in residential builds.

- Use HDF when you need durability without sacrificing too much on efficiency—great for commercial interiors.

- Reserve solid wood for detailed, custom, or high-end jobs where skilled labor is already planned for and justified.

Conclusion: Making the Right Choice for Your Project

Choosing the best material for mouldings ultimately depends on your project’s priorities—whether it’s cost, durability, finish quality, or aesthetics. MDF is often the preferred option for large-scale painted trim due to its affordability and ease of use. HDF offers a more robust alternative for high-traffic or moisture-sensitive environments where added strength matters. Solid wood remains the material of choice for custom, high-end spaces that demand a natural look and stain-grade finishes. By understanding how each material performs in real-world applications, you can make informed decisions that balance performance with budget—ensuring long-term value for your clients and smoother project execution for your team.