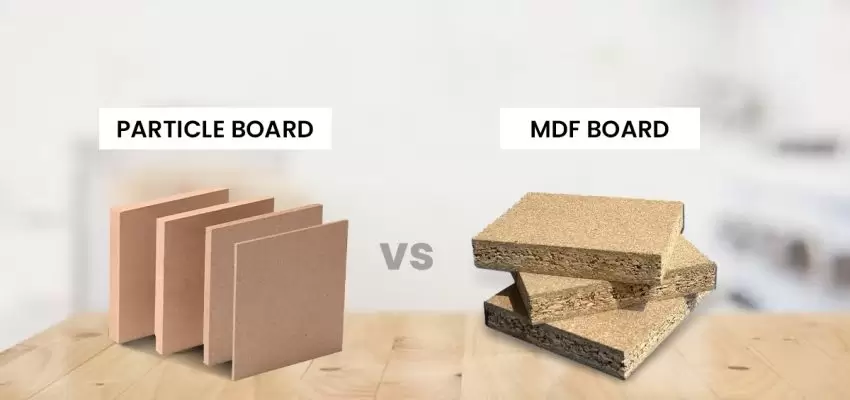

When selecting materials for construction, furniture, or cabinetry, the choice of engineered wood plays a crucial role in determining both the quality and cost-effectiveness of a project. Among the most commonly used options are MDF (Medium Density Fiberboard) and Particle Board, two materials that are often confused due to their similar appearance but are quite different in terms of composition, performance, and application.

Understanding the Construction and Material Composition of MDF and Particle Board

To make an informed decision between MDF and Particle Board, it is important to first understand how each material is constructed and what makes them unique in terms of composition and manufacturing process.

MDF (Medium Density Fiberboard)

MDF is made from fine wood fibers that are broken down, mixed with resin, and then compressed at high pressure to form a dense and smooth board. The fibers are typically derived from softwoods, which contribute to its high density and uniform texture. One of the key advantages of MDF is its smooth surface, which allows for easy finishing, making it ideal for painting. The dense nature of MDF also means it has better stability compared to other engineered wood products, with less tendency to warp or crack over time. However, MDF is generally more susceptible to moisture damage compared to higher-quality solid wood.

Particle Board

Particle board, on the other hand, is made from wood chips, sawdust, and other wood byproducts that are bonded together with resin and compressed to form panels. The composition of Particle Board makes it less dense and smoother than MDF, but it lacks the same strength and durability. While Particle Board can still perform well in low-stress applications, it is more prone to chipping, cracking, and moisture damage. It is also less stable and may experience more expansion and contraction when exposed to environmental changes. However, Particle Board’s cost-effectiveness makes it an attractive option for projects on a tighter budget.

Key Differences in Construction

The primary difference in construction between MDF and Particle Board lies in the materials used and the manufacturing process. MDF is made from finer, more uniform fibers, resulting in a stronger, denser product with a smooth, stable surface. Particle Board, however, is made from larger wood particles, resulting in a lighter, less durable board. This structural difference affects their performance in various applications.

- MDF is ideal for projects requiring a smooth, finished surface, and it offers better strength and durability.

- Particle Board is often used for more budget-friendly applications but lacks the durability and smooth finish that MDF provides.

Understanding these differences will help you choose the right material for your specific application, whether it’s for high-end cabinetry, furniture, or more cost-effective solutions.

Durability and Strength: Which Material Lasts Longer?

When it comes to durability and strength, both MDF and Particle Board have their advantages and limitations. The longevity of these materials largely depends on their construction, density, and the specific conditions in which they are used.

Durability of MDF

MDF is known for its strength and resistance to warping. Its smooth, dense surface allows it to withstand wear and tear better than many other engineered wood products. Because MDF is made from fine wood fibers that are tightly compressed, it offers superior stability and can handle heavier loads without significant degradation over time.

However, while MDF performs well in most indoor environments, it is susceptible to moisture damage. When exposed to water or high humidity for extended periods, MDF can swell and lose its integrity. This is why MDF is generally used in environments where it won’t come into direct contact with moisture—such as in furniture, cabinetry, and wall panels in dry areas.

Durability of Particle Board

Particle board, on the other hand, is generally less durable than MDF. While it can hold up well in light-duty applications, it is more prone to damage from impacts and moisture exposure. Particle board tends to be weaker and less stable compared to MDF, especially when subjected to heavy weight or extreme conditions.

The main benefit of Particle Board lies in its cost-effectiveness. However, this comes at the cost of durability. In environments where durability and longevity are essential, such as in kitchen cabinets or office furniture, Particle Board may not be the best choice unless it is laminated or veneered for added strength.

Which Material Lasts Longer?

- MDF is the better option for projects where durability and strength are key factors. Its dense and stable nature allows it to hold up longer under normal conditions, particularly when not exposed to moisture.

- Particle Board is more suited to budget-conscious projects where the material will not face significant stress or environmental challenges. However, its lower durability means it may need replacement sooner than MDF, especially in high-traffic or high-moisture areas.

Overall, if longevity is a key concern for your project, MDF is the better option. It offers higher durability, especially when used in dry, stable environments. Particle Board may be more affordable, but it has its limits in terms of performance and lifespan.

How to Select the Best Option for Your Budget and Application

When choosing between MDF and Particle Board, it’s essential to consider both your budget and the specific application for the material. Both materials have their place in construction and furniture manufacturing, but understanding the best scenario for each can help you make a more informed decision that balances cost and performance.

Budget Considerations

- MDF is more expensive than Particle Board, but its superior strength, smoothness, and durability may justify the extra cost, particularly in high-end projects where the quality of the finish is crucial. For furniture, cabinetry, and other interior applications that require a premium look, MDF offers better long-term value. If your budget allows for a slightly higher upfront cost, MDF provides a durable, reliable option that can be painted or veneered for a polished finish.

- Particle Board, on the other hand, is a more budget-friendly option and is ideal for projects that don’t require the durability or fine finish of MDF. It is commonly used in mass-produced furniture, affordable cabinetry, and applications where the appearance and longevity are secondary to the cost. For clients with strict budget constraints, Particle Board is a viable alternative, especially when aesthetics are not the top priority.

Application Considerations

- MDF is best used in applications where a smooth, consistent surface is necessary. It excels in areas where the material will be painted or finished, such as in furniture, cabinet doors, and wall panels. The ability of MDF to hold intricate details, such as carvings and design features, makes it the preferred choice for custom cabinetry and high-end furniture projects. Additionally, MDF is often the material of choice for acoustic panels and other specialized applications where its properties are beneficial.

- Particle Board is ideal for non-structural applications or for projects where the material will be covered with a veneer or laminate. It is commonly used in flat-pack furniture, affordable office furniture, and interior partitions that don’t require high strength or moisture resistance. It also works well in temporary installations or when cost is the most critical factor.

Long-Term Use vs. Short-Term Needs

When selecting a material, it’s important to think about whether your project requires long-term durability or if it’s more focused on short-term use. MDF is the better choice for long-term investments in high-traffic or heavily used areas, where performance and durability are key. For short-term or cost-sensitive projects, Particle Board can still offer sufficient performance without significantly increasing the cost.

In summary, selecting between MDF and Particle Board comes down to a balance of budget and application requirements. MDF is the superior material when long-term durability, smoothness, and strength are important, while Particle Board is perfect for budget-conscious projects that don’t require premium features.

Conclusion

In conclusion, both MDF and Particle Board have their unique advantages depending on the project requirements. MDF offers superior strength and a smooth surface, making it ideal for high-end applications, while Particle Board is a cost-effective solution for budget-conscious projects. By understanding the differences between these materials, builders and wholesalers can make the best choice for their specific needs, balancing both quality and cost.