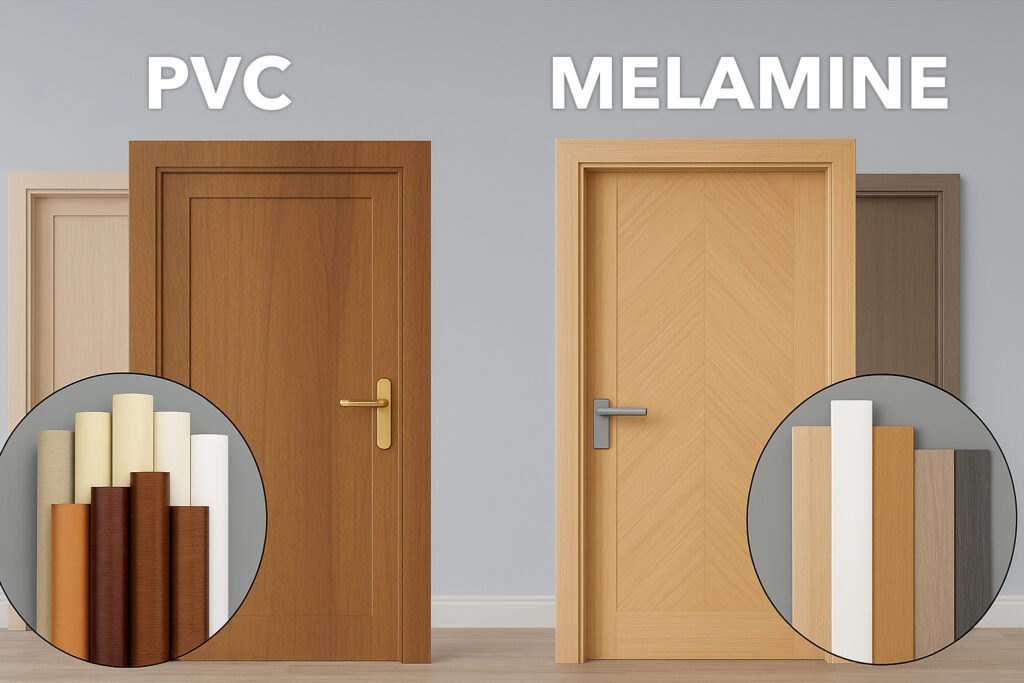

Imagine you’re overseeing a mid-scale residential project in a humid coastal region. You need hundreds of interior doors that are durable, cost-effective, and visually consistent. Your supplier gives you two options: melamine-faced laminate and PVC-wrapped surface coverings. Both look appealing at first glance—but what’s the real difference beneath the surface?

In this article, we’ll explore the technical composition, surface treatment, and performance characteristics of melamine laminates and PVC wraps—helping you make informed, material-based decisions for your next project.

Material Composition and Structure

1. What Is Melamine Laminate Made Of?

Melamine laminates are produced by pressing melamine-impregnated decorative paper onto high-density MDF or HDF substrates under high heat and pressure. The melamine resin, once cured, forms a hard, thermoset surface that is scratch-resistant, color-stable, and highly durable. This manufacturing method creates a precise, flat finish with excellent dimensional stability.

Due to the density and quality of both the substrate and resin, melamine laminates are more expensive than PVC wraps and are typically used in higher-end projects where surface hardness, flatness, and finish quality are critical. However, the rigid nature of melamine laminates means they are only suitable for flat or shallow molded designs, and edges require separate banding.

2. Understanding the Composition of PVC Wraps

PVC wraps are made from flexible thermoplastic films that are printed and embossed, then wrapped or vacuum-formed onto MDF, particleboard, or finger-jointed core substrates. The PVC film adapts well to 3D contours, making it ideal for shaker, profiled, or routed door designs.

PVC wraps are available in a wide range of finishes—from woodgrain to high-gloss or matte—and can wrap around edges, eliminating the need for banding. Because the material and process are relatively low-cost compared to melamine laminates, PVC wraps are more economical, making them suitable for budget-conscious projects or high-volume production.

3. Core Substrate Differences Between Melamine Laminates and PVC Wraps

Melamine laminates require dense, flat-core substrates like HDF or premium MDF to withstand the high-pressure lamination process. These cores ensure surface smoothness and structural integrity but add to the overall cost. Since melamine laminates cannot be wrapped, edge banding is essential.

PVC wraps are more forgiving and compatible with a wider range of core substrates, including standard MDF, laminated finger-jointed boards, and lightweight hollow cores. The film can wrap around edges and contours, providing better edge protection and moisture resistance in certain applications. However, lower-cost cores and weaker adhesives may reduce long-term durability.

In summary, melamine laminates are a higher-cost option with superior surface performance and dimensional stability, while PVC wraps offer flexibility and affordability, better suited for designs requiring edge wrapping or decorative texture.

Surface Appearance and Texture

1. Surface Texture and Finish: Matte, Glossy, or Woodgrain?

Melamine laminates offer clean, flat finishes with printed decor paper fused under high pressure. The surface comes in matte, satin, or semi-gloss, but texture options are limited. Though some higher-end melamine laminates incorporate embossed-in-register (EIR) for visual depth, this increases cost. Overall, melamine laminates excel in sleek, modern finishes but lack true 3D texture.

PVC wraps provide a wider variety of textures and finishes, from woodgrain embossing to high-gloss or soft-touch matte. The thermoplastic film can wrap around profiles and grooves, making it ideal for detailed or contoured designs. Its cost-effectiveness and aesthetic range make it attractive for projects requiring visual richness on a tighter budget.

2. How Do Melamine Laminates and PVC Wraps Look and Feel?

Melamine laminates have a hard, smooth feel with a rigid surface. They’re visually uniform and durable, but generally lack tactile realism. They’re ideal for high-end minimalistic interiors or commercial spaces where surface consistency and scratch resistance matter.

PVC wraps feel softer and warmer, with embossed grains that add texture and depth. They look and feel closer to natural wood, especially in shaker or rustic styles. Though less rigid, PVC’s versatility in design makes it a popular option for mid-range or decorative applications.

3. Appearance Matters: Comparing Aesthetic Qualities

Melamine laminates are best for premium flat panel doors that prioritize visual clarity, sharp edges, and durable finishes. They suit commercial or upscale residential interiors.

PVC wraps, with their broader design flexibility and affordability, are ideal for profiled doors, decor-driven projects, or cost-sensitive residential developments. While melamine laminates deliver surface purity and hardness, PVC wraps offer warmth, realism, and edge-to-edge consistency.

Performance Comparison

1. Workability: Cutting, Edging, and Application

Melamine laminates are pressed flat and require precise cutting and edge banding. They work best on stable, flat substrates like HDF or premium MDF. Processing involves more rigid equipment and is less tolerant of error, which increases handling cost. They’re not suitable for wrapping or profiled surfaces.

PVC wraps are easier to process. The flexible film can be vacuum-formed or wrapped, covering both face and edges without separate banding. It allows for faster assembly in mass production and adapts well to grooves or panel details. This reduces labor time and makes PVC more efficient for certain design types.

2. Ideal Applications for Each Type of Surface Finish

Melamine is ideal for:

- High-end residential or commercial interiors

- Flat panel or molded doors requiring excellent surface hardness

- Areas needing good scratch and chemical resistance

- Projects where cost is secondary to appearance and stability

PVC is ideal for:

- Budget-friendly residential or multi-family housing

- Doors with shaker or raised panel designs

- Moisture-prone spaces like bathrooms or kitchens

- Fast-turnover projects needing efficient processing

Melamine vs. PVC: Which One Fits Your Project Better?

The choice between melamine laminates and PVC wraps depends on your project’s budget, design complexity, and environmental requirements.

If your project demands higher surface quality, excellent scratch resistance, and a clean, modern aesthetic, melamine is the better option—especially for commercial spaces, premium residential interiors, or projects where long-term appearance stability is key. Its higher material and processing cost is justified in environments where performance and precision matter more than price.

On the other hand, if you’re managing a cost-sensitive development, working with profiled or shaker-style doors, or installing in humid or high-turnover spaces, PVC offers a highly practical solution. Its design flexibility, moisture resistance, and lower processing cost make it ideal for multi-family housing, kitchens, bathrooms, or large-volume housing projects.

Ultimately, both materials have distinct strengths. Selecting the right one means balancing performance expectations, design goals, and cost realities to meet your project’s specific needs.

Conclusion: Making the Right Choice Based on Material Differences

When selecting between melamine laminates and PVC wraps , understanding the core differences in material composition, surface finish, performance, and application is essential. Melamine offers a cost-effective, durable surface for flat designs in stable environments, while PVC provides flexibility, richer texture options, and better moisture resistance—especially for contoured doors or high-humidity settings.

For builders and wholesalers, the decision isn’t about which material is universally better, but which one better fits the needs of your project. By evaluating design complexity, environmental exposure, budget constraints, and aesthetic goals, you can choose the surface finish solution that delivers both visual appeal and long-term performance.