When selecting veneer doors for your home or office, understanding the different styles available can help you choose the best option to match your design preferences. Homeowners and designers often ask questions about Can Grooved Style Veneer Doors be customized for different aesthetics?

Yes, grooved style veneer doors can be customized with a variety of groove patterns and finishes to match different aesthetic preferences, from modern and industrial to classic and decorative styles. This versatility makes them a popular choice for diverse design needs.

Veneer doors have become a staple in modern interior design due to their aesthetic appeal, versatility, and cost-effectiveness. Understanding the different types of veneer doors, their cuts, and styles can help homeowners, designers, and builders make informed decisions. This comprehensive guide explores the popular types of veneer doors, focusing on their cutting techniques, common veneers, and various styles.

Cut

The way veneer is cut from the log significantly impacts the appearance and characteristics of the final product. There are several common cutting techniques used to produce veneer, each with a specific purpose and aesthetic result:

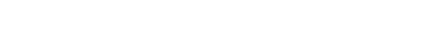

PLAIN SLICED VENEER

Plain sliced veneer, also known as flat-cut veneer, is created by slicing the log parallel to the center. This method reveals a cathedral grain pattern that is both aesthetically pleasing and versatile for various applications.

Maximizing Visual Appeal:

The prominent cathedral or heartwood grain pattern is highly attractive, making plain sliced veneer suitable for visible surfaces like doors and panels.

Cost Efficiency: This method produces a high yield of veneer, making it a cost-effective choice for many projects.

Usage: Commonly used in doors, panels, and furniture for its traditional look.

Versatile Aesthetics: The prominent grain pattern works well in both modern and traditional designs.

Efficient Production: Produces a high amount of usable veneer.

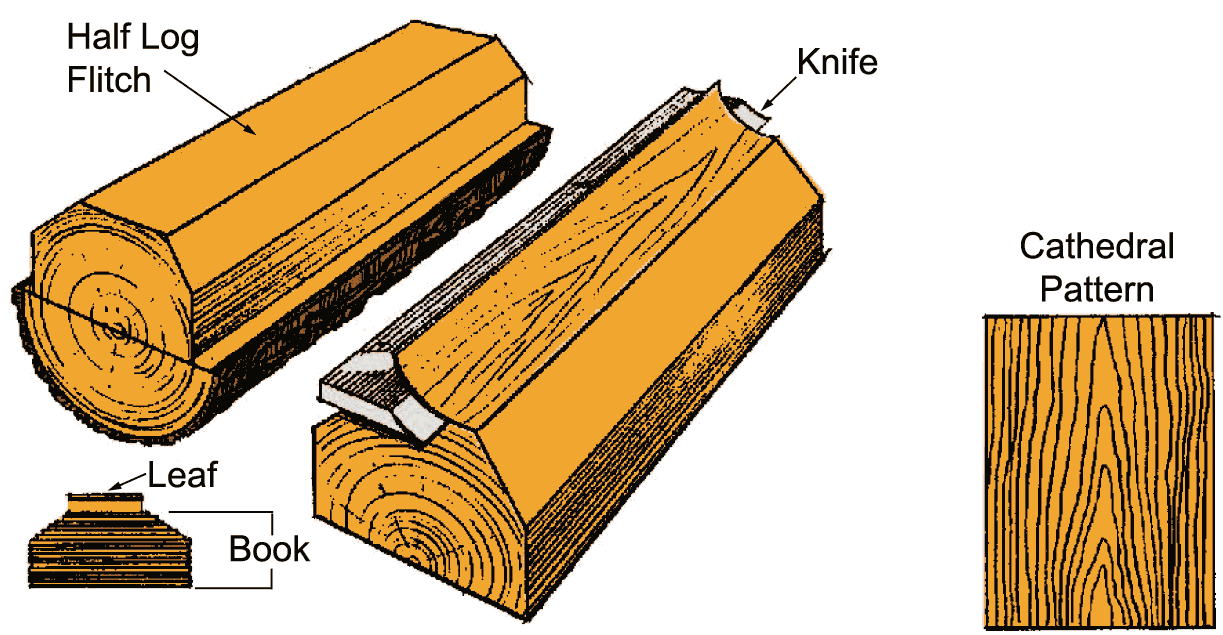

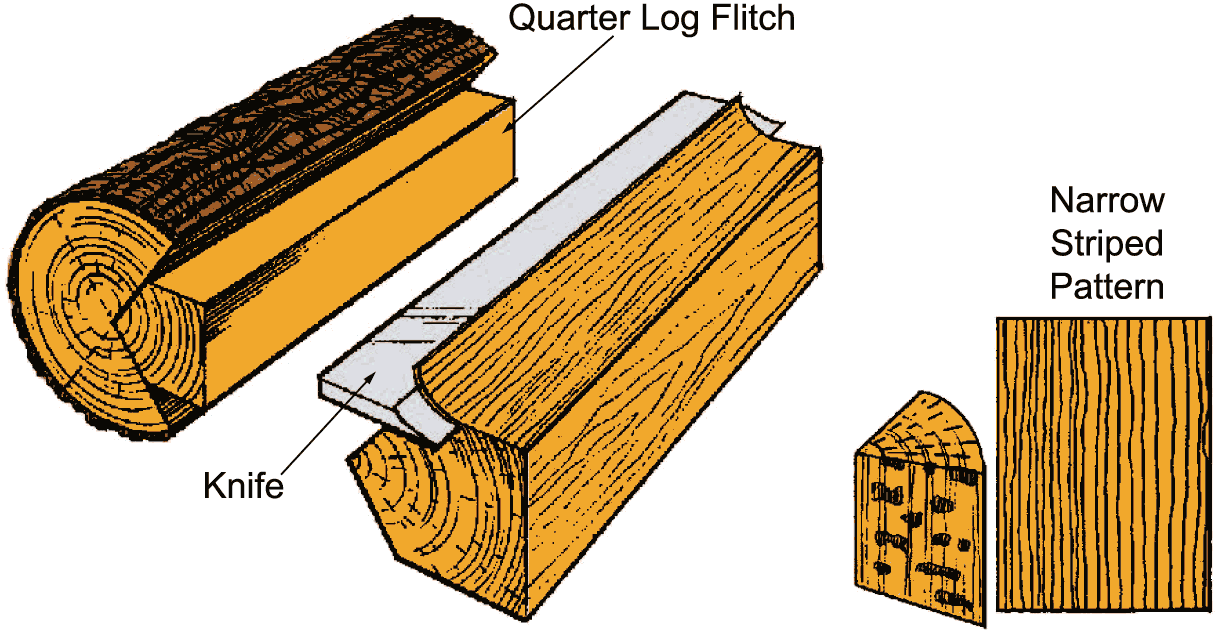

QUARTER SLICED VENEER

Quarter sliced veneer is produced by cutting the log at a right angle to the growth rings. This method results in a straight grain pattern with a more uniform appearance than plain sliced veneer.

Enhancing Stability: Quarter slicing produces a more stable veneer with reduced chances of warping and splitting.

Uniform Grain: Provides a consistent and elegant appearance, suitable for high-end applications.

Appearance: Straight, uniform grain pattern.

Usage: Ideal for applications requiring a refined and consistent look, such as high-end furniture and cabinetry.

Sophisticated Look: The consistent grain pattern offers a sophisticated and elegant appearance.

Durability: More stable and less prone to warping.

RIFT CUT VENEER

Rift cut veneer is produced by slicing the log at a slight angle to the radial line. This technique is often used for species with coarse grains, such as oak, to minimize the appearance of flake.

Achieving Clean Lines: The rift cut method produces a very straight grain, perfect for sleek and contemporary designs.

Reducing Flake: Minimizes the appearance of flake, especially in species like oak.

Appearance: Straight grain with a uniform texture, often free of flake.

Usage: Commonly used in modern and minimalist designs, where a clean and uniform look is desired.

Modern Aesthetics: The straight grain is ideal for modern and minimalist designs.

Less Waste: Produces less waste compared to other slicing techniques.

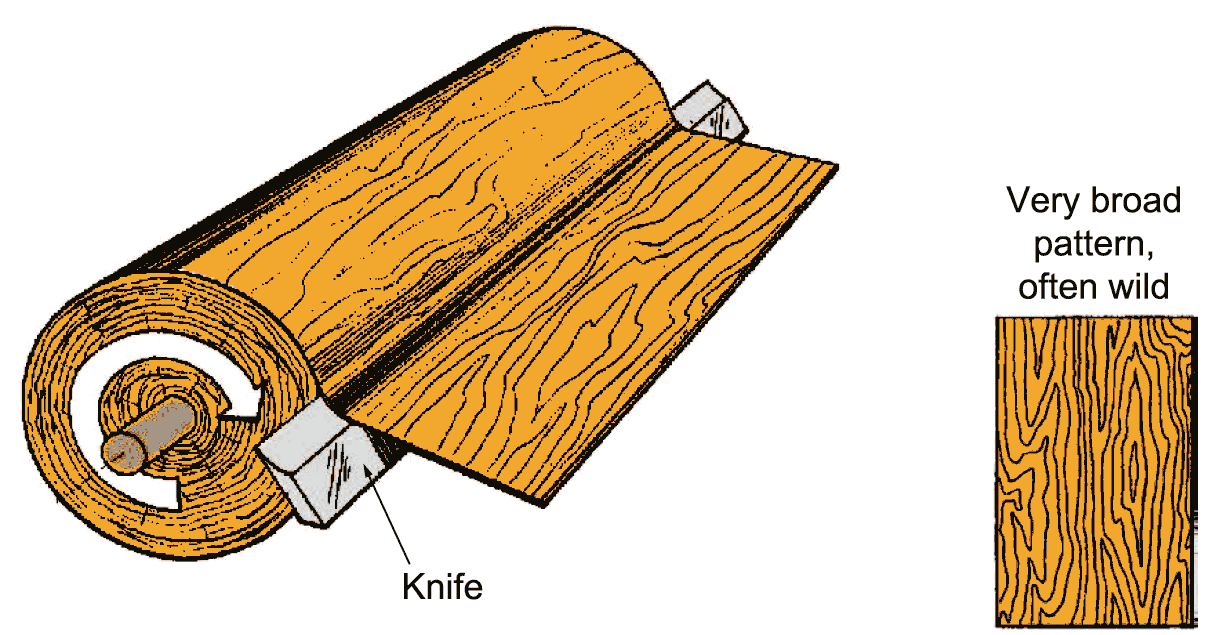

ROTARY CUT VENEER

Rotary cut veneer is created by rotating the log against a stationary blade, peeling off a continuous sheet of veneer. This method maximizes the yield from the log and is the most efficient way to produce veneer.

Maximizing Yield: Rotary cutting produces the maximum amount of veneer from a log, making it highly economical.

Unique Patterns: The method creates bold, variegated grain patterns that add character to various designs.

Appearance: Bold, variegated grain pattern that can appear somewhat wild and inconsistent.

Usage: Often used in applications where cost is a significant factor, such as plywood and commercial-grade furniture.

Common Door Veneers

Veneer doors can be made from a variety of wood species, each offering unique characteristics and aesthetics. While maple, oak, and walnut are popular choices, melamine, PVC, and reconstituted/artificial veneers are also widely used.

Maple

Appearance: Light-colored wood with a subtle grain pattern.

Usage: Popular for its clean, smooth finish, often used in modern and contemporary designs.

Advantages: Durable and easy to finish, providing a sleek and polished look.

Oak

Appearance: Strong, prominent grain pattern with variations in color.

Usage: Commonly used in traditional and rustic designs, valued for its strength and character.

Advantages: Highly durable and resistant to wear, making it ideal for high-traffic areas.

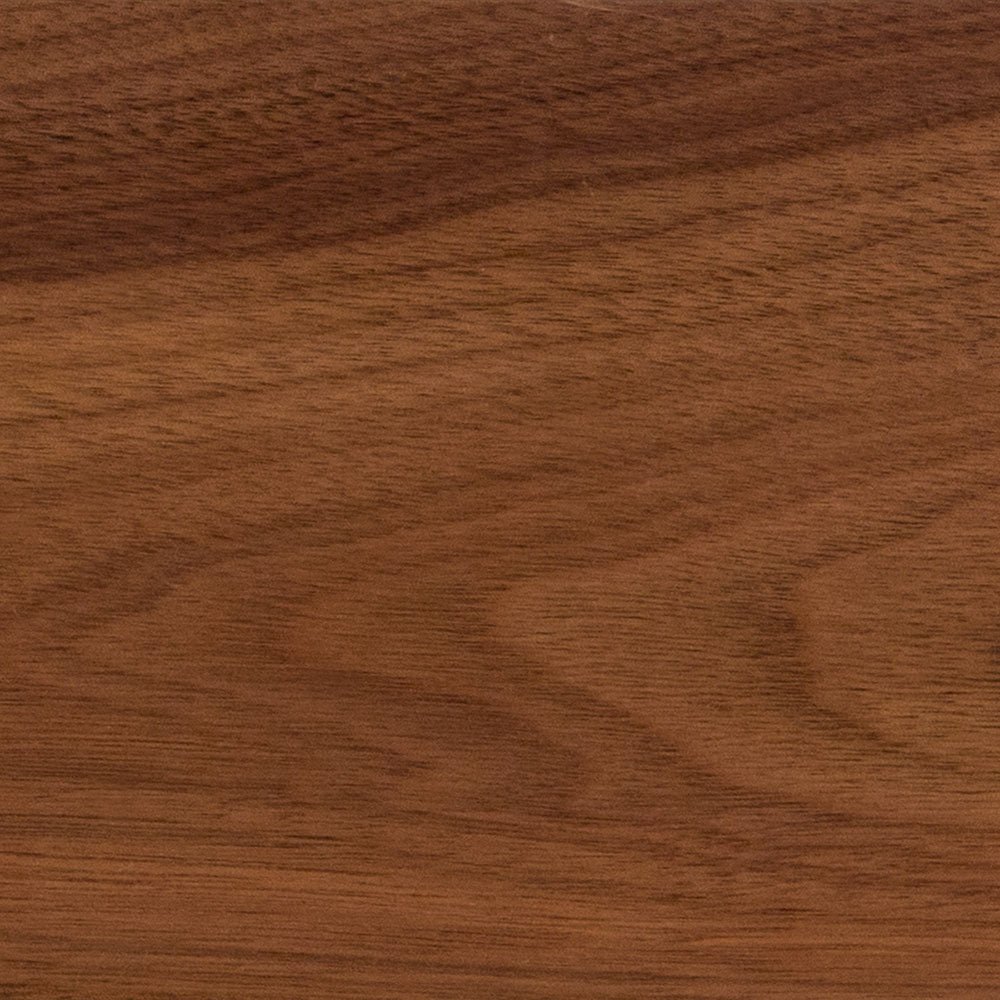

Walnut

Appearance: Rich, dark wood with a distinctive, elegant grain pattern.

Usage: Often used in high-end furniture and cabinetry, prized for its luxurious appearance.

Advantages: Offers a deep, warm color that enhances any interior space.

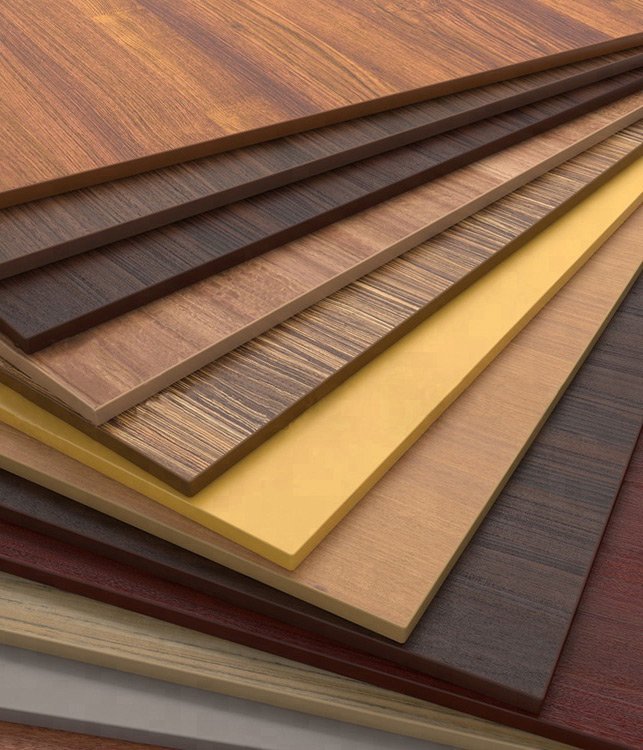

Melamine Veneer

Melamine veneer consists of a decorative paper layer impregnated with melamine resin, bonded to a substrate such as MDF or particleboard. The melamine surface provides a durable and aesthetically versatile finish.

Durability: Resistant to scratches, moisture, and heat, making it ideal for high-traffic areas and commercial applications.

Variety: Available in a wide range of colors, patterns, and textures, including realistic wood grains and solid colors.

Maintenance: Easy to clean and maintain, requiring only a simple wipe-down with a damp cloth.

PVC Veneer

PVC (Polyvinyl Chloride) veneer is made from a type of plastic that offers high durability and resistance to environmental factors. The PVC layer is applied to a core material, often MDF or particleboard.

Moisture Resistance: Highly resistant to moisture, making it suitable for use in humid environments like bathrooms and kitchens.

Low Maintenance: Requires minimal upkeep and can be easily cleaned with a damp cloth.

Cost-Effective: Generally more affordable than other veneer types, offering a budget-friendly option.

Reconstituted/Artificial Veneer

Reconstituted veneer, also known as engineered or artificial veneer, is made from fast-growing plantation timber. The wood is processed to remove imperfections, dyed, and reassembled to mimic the appearance of more expensive and exotic wood species.

Eco-Friendly: Uses sustainable timber and reduces reliance on natural forests.

Consistency: Offers a uniform grain and color, ideal for large-scale projects requiring consistency.

Stability: Less prone to warping and cracking compared to natural wood veneer.

Different Styles

Veneer doors come in a variety of styles, each offering unique design possibilities. Here are some popular styles:

Grooved Style

Description: Grooved style veneer doors feature decorative grooves or lines carved into the surface of the veneer. These grooves can create a range of patterns, from simple linear designs to intricate geometric shapes.

Advantages

- Aesthetic Appeal: Adds texture and visual interest to the door, enhancing the overall design of the space.

- Customization: The grooves can be customized to match specific design themes and preferences.

Applications

- Modern Interiors: Ideal for contemporary and minimalist designs, providing a sleek and stylish look.

- Accent Doors: Perfect for use as accent doors in living rooms, bedrooms, and offices.

Lightly Carved Style

Description: Lightly carved style veneer doors feature shallow carvings that create subtle patterns and designs on the door surface. These carvings can range from simple motifs to more elaborate decorative elements.

Advantages

- Elegance: The light carvings add a touch of elegance and sophistication to the door.

- Versatility: Suitable for a wide range of design styles, from traditional to modern.

Applications

- Residential Use: Ideal for living rooms, dining rooms, and bedrooms, adding a decorative element to the space.

- Commercial Spaces: Provides a refined and elegant appearance for office and hotel interiors.

Flush Style

Description: Flush style veneer doors have a smooth, flat surface with no visible joints or patterns. This style offers a clean and minimalist look, making it a popular choice for modern interiors.

Advantages

- Simplicity: The simple and clean design complements contemporary and minimalist interiors.

- Easy Maintenance: The flat surface is easy to clean and maintain.

Applications

- Modern Homes: Ideal for modern and minimalist designs, providing a sleek and unobtrusive look.

- Commercial Spaces: Perfect for offices and commercial buildings, offering a professional and clean appearance.

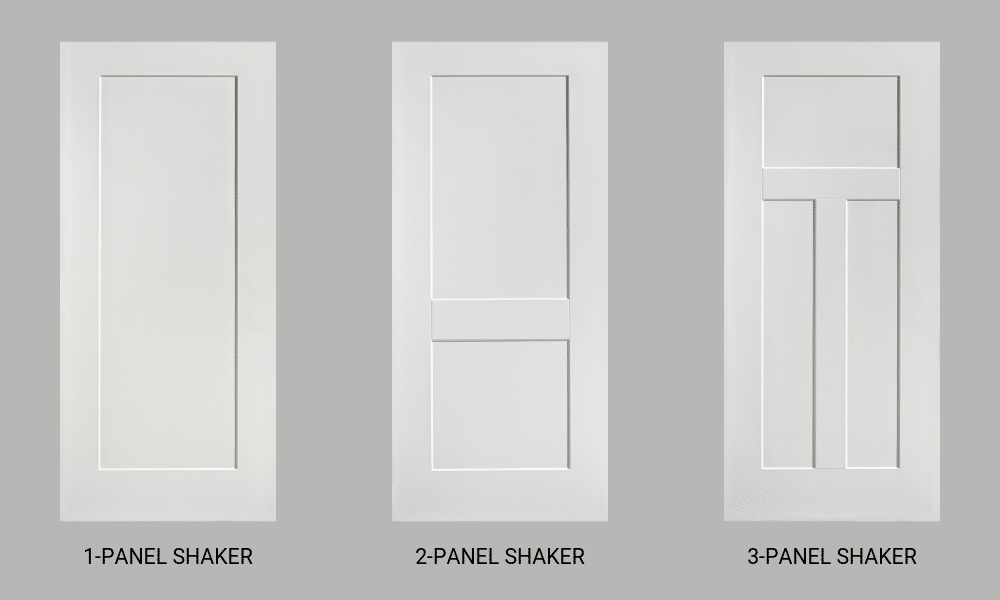

Panel Style

Panel StylePanel style veneer doors feature raised or recessed panels that add depth and dimension to the door. These panels can be arranged in various configurations, creating a classic and timeless look.

Advantages

- Aesthetic Versatility: The panel design can be tailored to suit both traditional and contemporary settings.

- Visual Interest: Adds depth and character to the door, enhancing the overall design.

Applications

- Classic Homes: Ideal for traditional and classic interiors, providing a timeless and elegant appearance.

- High-End Residences: Suitable for luxury homes, offering a sophisticated and detailed look.

Conclusion

Veneer doors, with their combination of beauty, durability, and cost-effectiveness, offer an excellent solution for both residential and commercial applications. Understanding the different types of veneer cuts, common veneer materials, and various door styles can help you select the perfect veneer door to match your aesthetic and functional needs. Whether you prefer the uniform grain of quarter sliced veneer, the durability of melamine veneer, or the elegance of lightly carved styles, there is a veneer door option to suit every design preference and budget.