UWG Molded Door

Popular, Versatile, Cost-Effective

Molded doors are one of UWG’s most popular interior door options, combining cost-effectiveness with versatile designs.

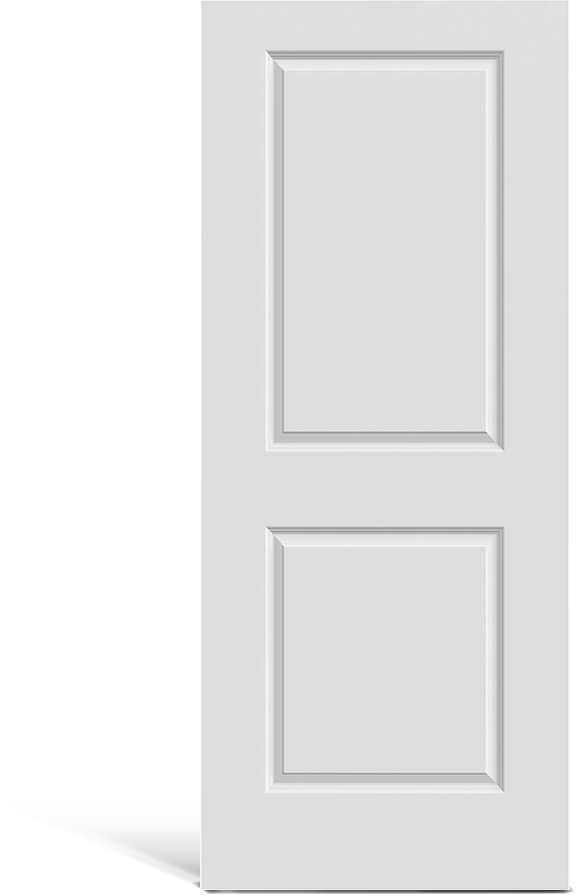

Slab Molded Door

A slab door is just the door panel itself. No frame, no hinges, no hardware.

MOQ: 100 doors

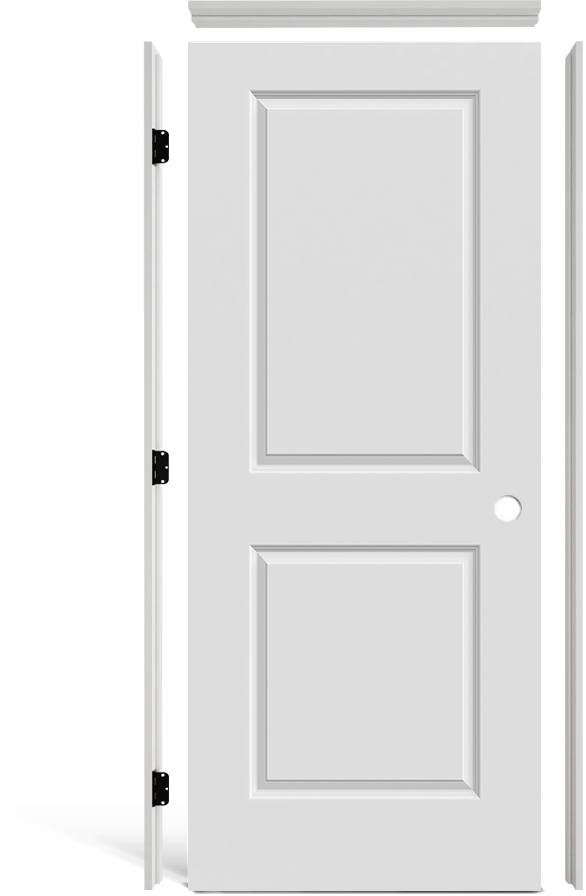

RTA Molded Door

An RTA door comes with all frame parts and is pre-drilled for locks and hinges.

MOQ: 100 doors

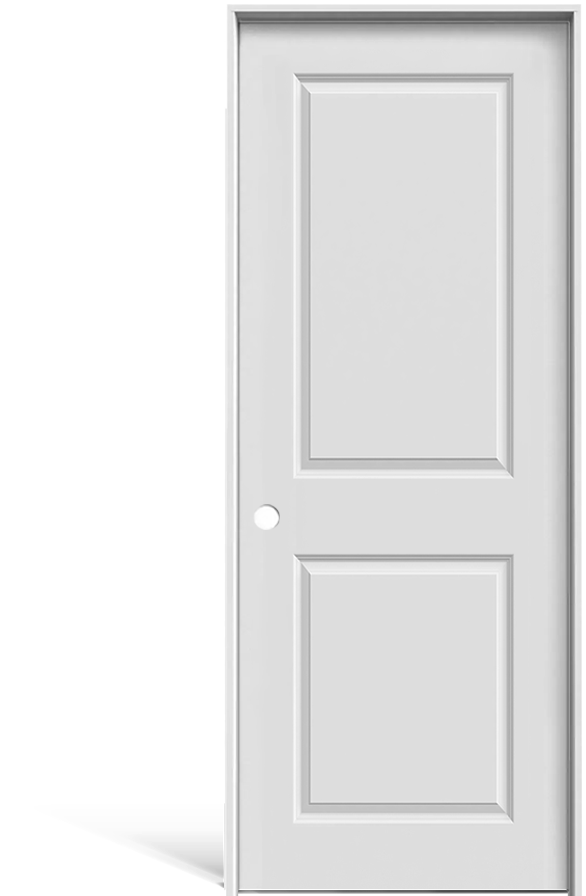

Prehung Molded Door

A prehung door comes fully assembled with the door slab, frame, and attached hinges.

MOQ: 100 doors

Custom Services

Tailor products to your project specifications, even for large-scale orders.

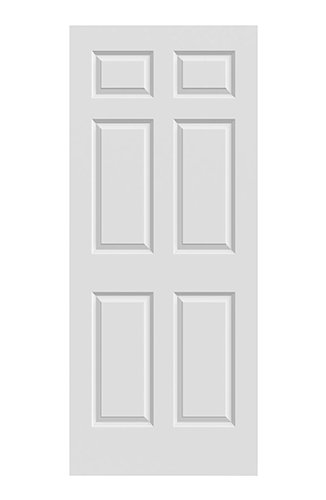

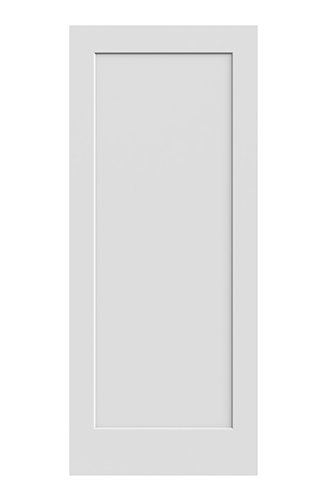

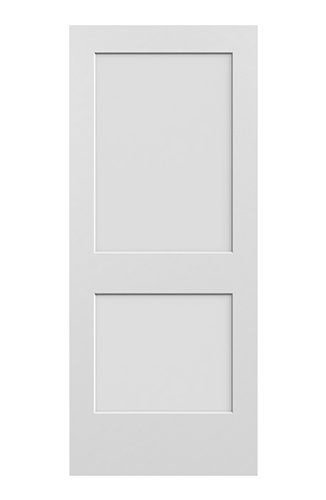

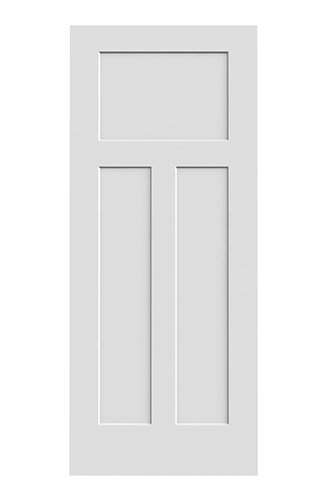

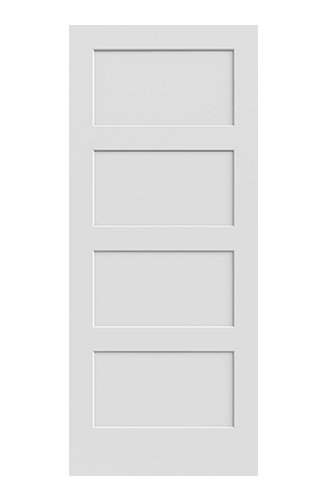

Molded Door Types

UWG offers a variety of molded doors, from classic raised-panel designs to sleek, modern profiles, including Shaker-style replicas — providing builders with versatile and cost-effective interior options.

Molded 1 Panel

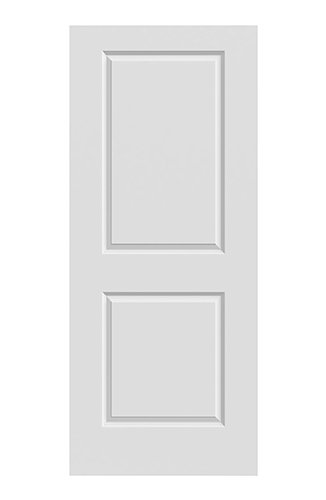

Molded 2 Panel

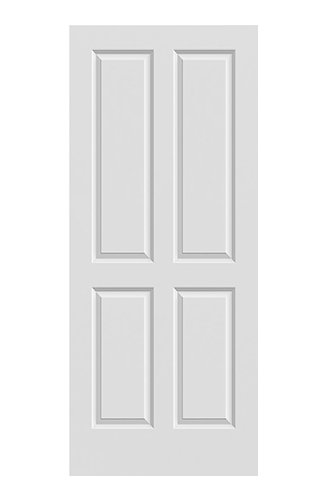

Molded 4 Panel

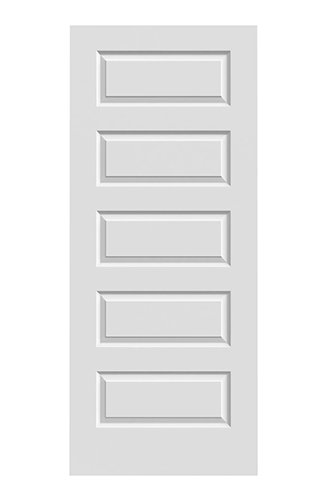

Molded 5 Panel

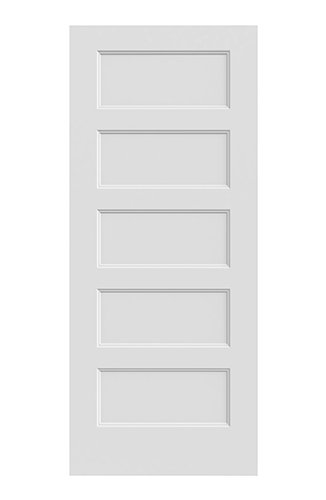

Molded 5 Panel

Molded 6 Panel

Shaker Style 1 Panel

Shaker Style 2 Panel

Shaker Style 3 Panel

Shaker Style 3 Panel

Shaker Style 4 Panel

Shaker Style 5 Panel

Doors size

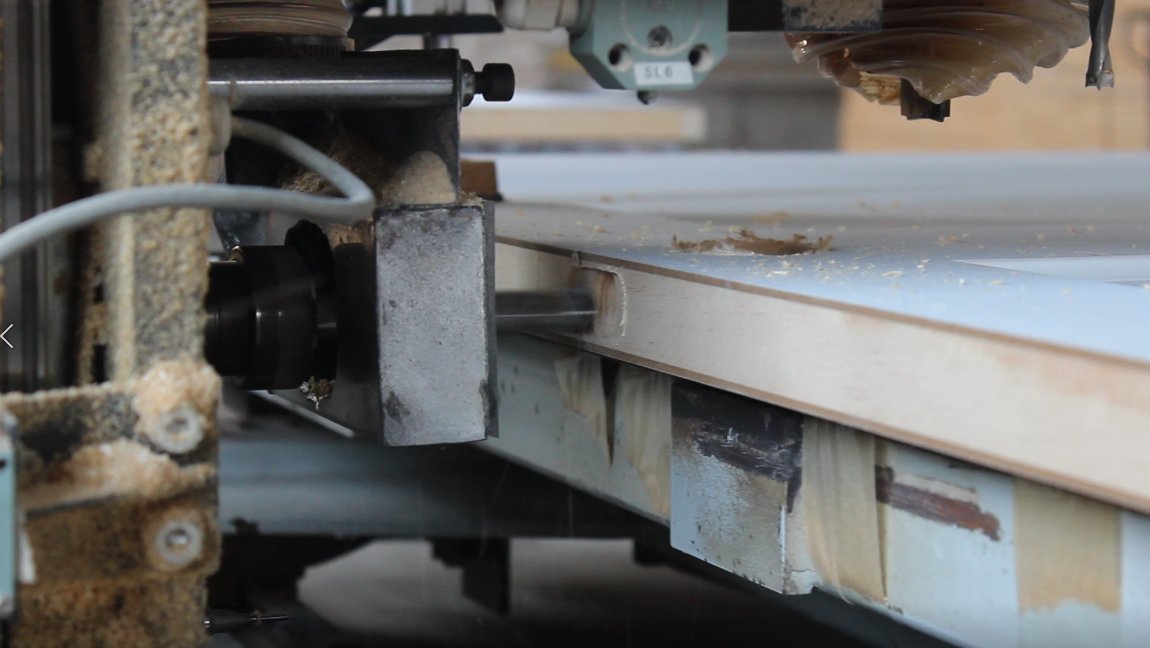

Where Precision Defines Every Fit.

UWG ensures every door is crafted to precise measurements for a perfect fit. From width to height, our factories follow strict standards and advanced production systems to maintain consistency across every size and style.

| 80″ | 84″ | 96″ | |

|---|---|---|---|

| 12″ | |||

| 14″ | |||

| 15″ | |||

| 16″ | |||

| 18″ | |||

| 20″ | |||

| 22″ | |||

| 24″ | |||

| 26″ | |||

| 28″ | |||

| 30″ | |||

| 32″ | |||

| 34″ | |||

| 36″ | |||

| 38″ | |||

| 40″ |

Tell us what you need

We’ll deliver the right molded doors at the right price — right on schedule.

Swing Molded Doors

Classic interior solutions.

Barn Molded Doors

Smooth-sliding style.

Bifold Molded Doors

Classic interior solutions.

Pocket Molded Doors

Hidden & seamless.

Complete Your Interior Door Project

From surface finishes and textures to core materials, every detail can be tailored to meet your specific needs.

Door Core

UWG offers versatile options to meet different project needs, from lightweight hollow cores to sturdy solid cores with customizable material combinations.

Hollow Core – Filled with honeycomb paper or EPS foam, making the door lightweight and cost-effective while maintaining structural stability.

Solid Core – Filled with particleboard, Hollow core board, MDF strips, or plywood, providing a heavier, more durable door with better sound insulation and a premium feel.

Door Finish

UWG molded doors are available in different finishes to suit your project needs, offering flexibility and convenience for builders.

Primed – Smooth white base coat, ready for painting. Saves prep time and ensures a clean, professional finish.

Painted – Fully finished and ready to install, available in classic or custom colors. Resists chips and scratches.

Door Texture

UWG molded doors are available in two surface textures, giving you the right look and feel for any project.

Smooth – Flat, even surface for a clean, modern look or for custom painting.

Textured – Wood-grain effect adds depth and a natural appearance, giving the feel of real wood.

DOOR Hardware

Our door hardware is designed for durability, style, and seamless operation, offering a variety of options to suit any interior or specialty door application.

Locks – Provide security and privacy with options like keyed entry, privacy, and passage locks.

Hinges – Ensure smooth and reliable door movement, available in standard, ball-bearing, and hidden designs.

Specialty Door Hardware – Includes hardware systems for barn doors, pocket doors, folding doors, and other specialized door types.

UWG Molded Doors won’t let you down

Better Quality

Consistent & Durable.

Premium molded skins, stable cores, and strict QC deliver doors that are uniform in appearance and performance.

Lower Price

Factory-Direct Advantage.

Mass production capability and direct supply chain management allow competitive pricing ideal for large projects.

Faster Service

Quick Turnaround.

Efficient production lines and flexible shipping options ensure your orders arrive on time, every time.

Need more help?

Have questions or need more product information?

Our team is ready to offer customized solutions and expert support.

Explore More

Interior Doors

Cabinets & Countertops

Moulding & Millwork

Exterior Doors

Manufactured Components

Lumber

Plywood & Sheathings

Packages

Windows

Flooring

Stairs & Stair Parts

Decking