UWG SHAKER Door

Classic • Minimal • Sturdy

At UWG, you can get better-quality Shaker door at more competitive prices — helping you stand out in your local market.

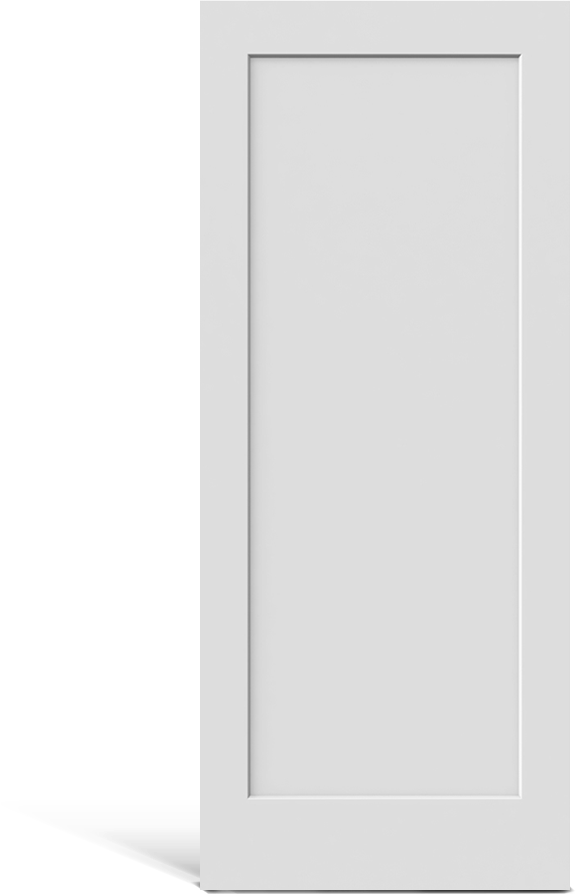

Slab Shaker Door

A slab door is just the door panel itself. No frame, no hinges, no hardware.

MOQ: 100 doors

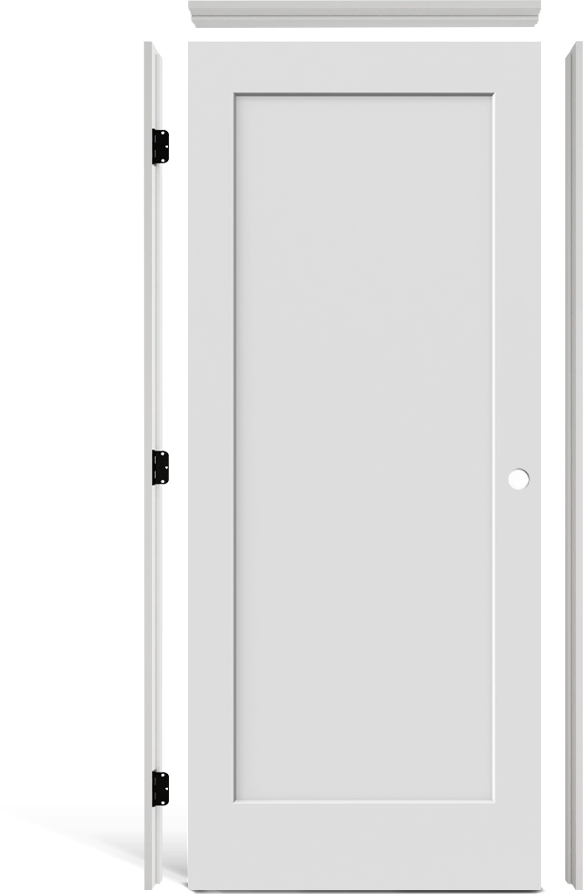

RTA Shaker Door

An RTA door comes with all frame parts and is pre-drilled for locks and hinges.

MOQ: 100 doors

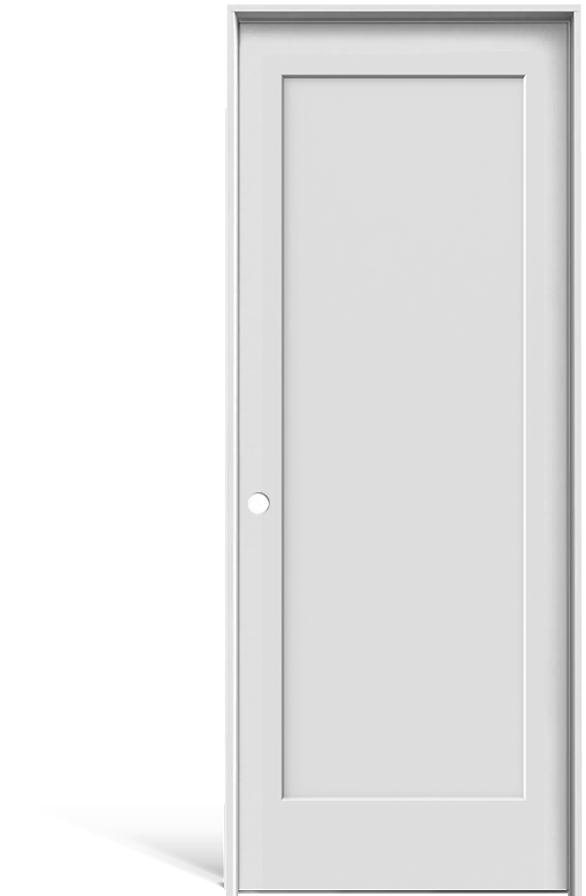

Prehung Shaker Door

A prehung door comes fully assembled with the door slab, frame, and attached hinges.

MOQ: 100 doors

Custom Services

Tailor products to your project specifications, even for large-scale orders.

Shaker Door Panel Types

Shaker doors are distinguished not only by their clean lines but also by the number and arrangement of panels they feature.

Shaker 1 Panel

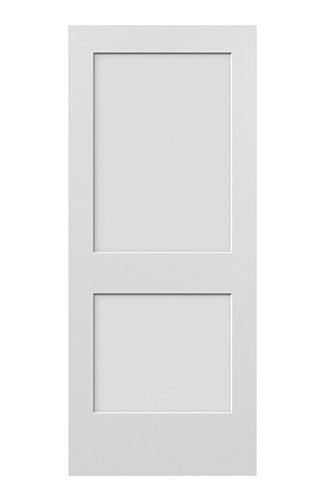

Shaker 2 Panel

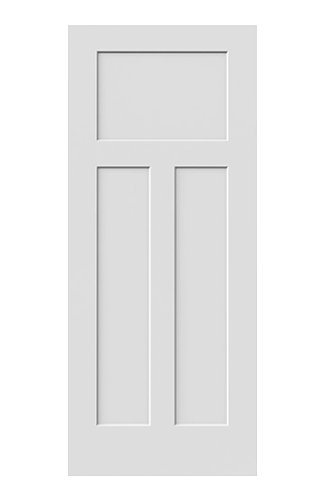

Shaker 3 Panel

Shaker 3 Panel

Shaker 4 Panel

Shaker 5 Panel

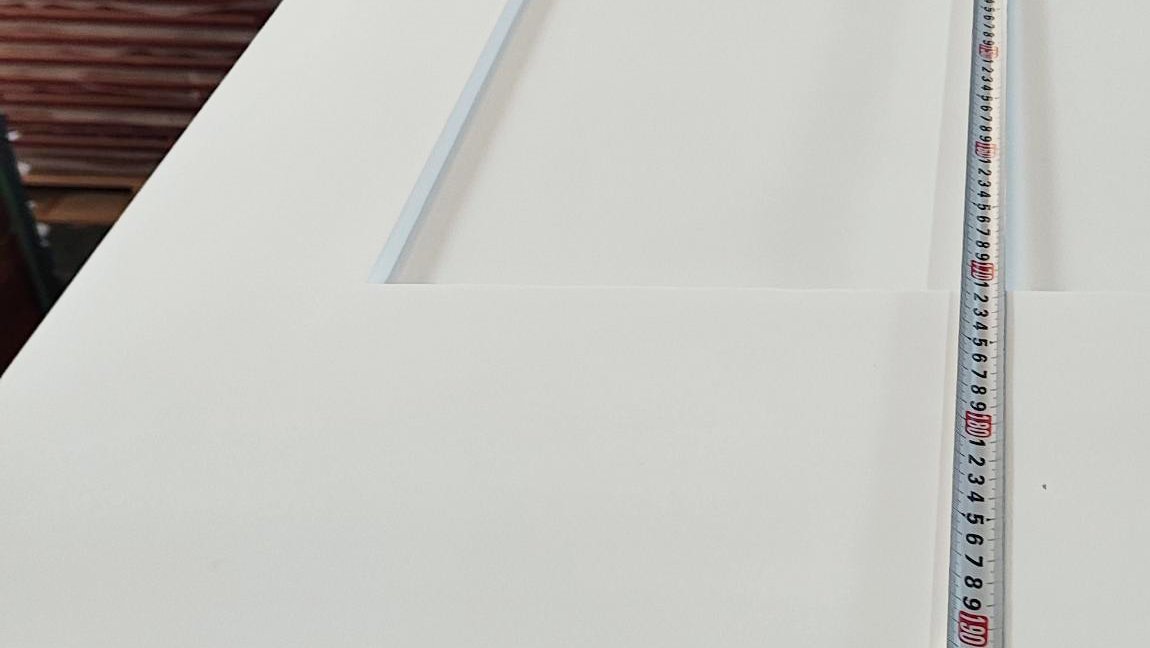

Doors size

Where Precision Defines Every Fit.

UWG ensures every door is crafted to precise measurements for a perfect fit. From width to height, our factories follow strict standards and advanced production systems to maintain consistency across every size and style.

| 80″ | 84″ | 96″ | |

|---|---|---|---|

| 12″ | |||

| 14″ | |||

| 15″ | |||

| 16″ | |||

| 18″ | |||

| 20″ | |||

| 22″ | |||

| 24″ | |||

| 26″ | |||

| 28″ | |||

| 30″ | |||

| 32″ | |||

| 34″ | |||

| 36″ | |||

| 38″ | |||

| 40″ |

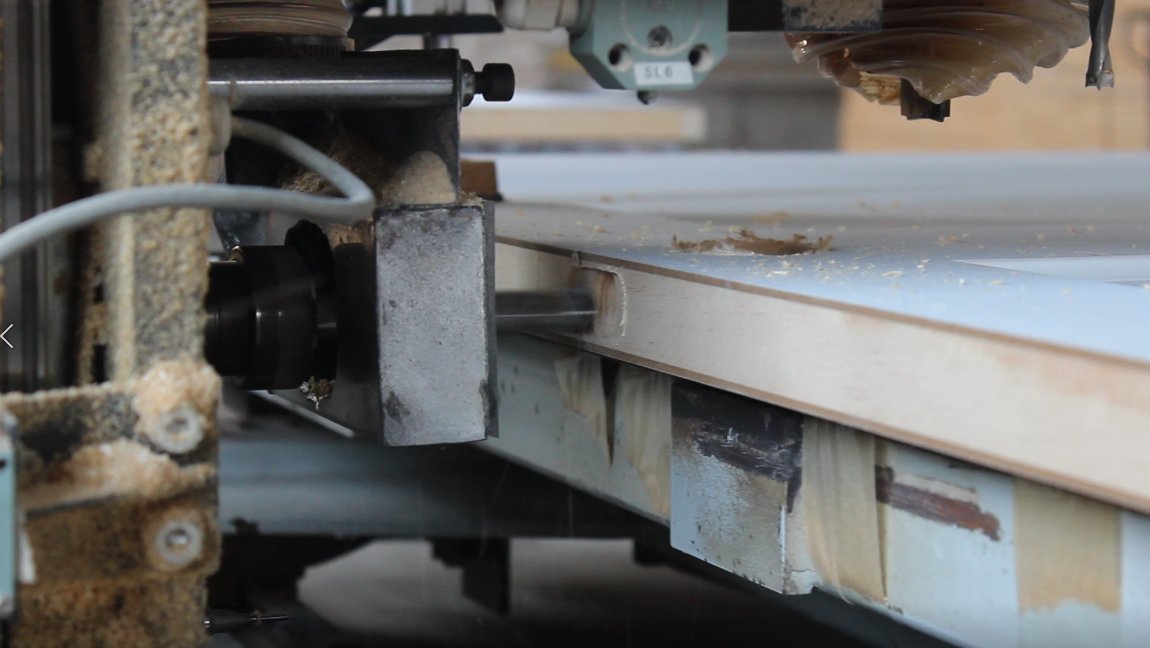

See How Our Shaker Doors Are Made

Take a closer look at our factory and see how we craft every Shaker door with precision and care. From high-quality materials to skilled craftsmanship, experience the process that makes our doors both durable and timeless.

Swing Shaker Doors

Classic interior solutions.

Barn Shaker Doors

Rustic style.

Bifold Shaker Doors

Space-saving.

Pocket Shaker Doors

Hidden design.

Complete Your Interior Door Project

From surface finishes and textures to core materials, every detail can be tailored to meet your specific needs.

Door Skeleton

The door skeleton defines the internal structure of Shaker doors. Different core constructions provide varying strength, stability, and weight options to suit different door applications.

Solid Wood – Provides maximum strength and stability; suitable for premium doors requiring durability.

Solid Wood with Tubular Chipboard – Combines solid wood frame with tubular chipboard; cost-effective while maintaining structural integrity.

Solid Wood with Particle Chipboard – Combines solid wood frame with particle chipboard; stable and durable.

DOOR Panel Thickness

The center panel thickness of Shaker doors can be adjusted and customized, typically available in 8mm or 12mm to suit different door heights and overall door thickness.

8mm – For doors up to 80" high with 35mm thickness.

12mm – For doors 80" high with 45mm thickness or any doors 96" high.

Door Finish

Shaker doors are available in painted, primed, and more finishes, allowing customization to match any interior style and design preference.

Primed – Smooth white base coat, ready for painting. Saves prep time and ensures a clean, professional finish.

Painted – Fully finished and ready to install, available in classic or custom colors. Resists chips and scratches.

DOOR Hardware

Our door hardware is designed for durability, style, and seamless operation, offering a variety of options to suit any interior or specialty door application.

Locks – Provide security and privacy with options like keyed entry, privacy, and passage locks.

Hinges – Ensure smooth and reliable door movement, available in standard, ball-bearing, and hidden designs.

Specialty Door Hardware – Includes hardware systems for barn doors, pocket doors, folding doors, and other specialized door types.

UWG Shaker Doors won’t let you down

Better Quality

Built to Last.

We use premium materials and strict QC standards to ensure consistent quality in every product — from construction to finish.

Lower Price

Factory-Direct Advantage.

Work directly with the manufacturer to eliminate unnecessary markups. Get competitive pricing without compromising on quality.

Faster Service

Responsive & On Time.

From fast quoting to on-schedule delivery, we understand how important timing is to your projects. Our team is quick, clear, and committed.

Need more help?

Have questions or need more product information?

Our team is ready to offer customized solutions and expert support.

Explore More

Interior Doors

Cabinets & Countertops

Moulding & Millwork

Exterior Doors

Manufactured Components

Lumber

Plywood & Sheathings

Packages

Windows

Flooring

Stairs & Stair Parts

Decking