In residential construction, waste in trim and moulding procurement often remains invisible—until it erodes margins, delays schedules, or disrupts project flow. Small inefficiencies like overordering, mismeasurement, or mishandling rarely trigger alarms on their own, but collectively they represent a significant drain on operational performance. Efficient procurement isn’t just about trimming costs—it’s about ensuring that the right materials, in the right quantities, arrive at the right time and are used with precision. So where does waste originate, and what can residential builders do to address it proactively?

Reducing waste in moulding and trim procurement requires precision, standardization, and coordination. Builders should start with accurate, project-specific takeoffs to avoid overordering and use standardized profiles across units to simplify purchasing and reuse. Coordinating deliveries with installation schedules prevents damage and reduces storage waste. Onsite, teams can minimize offcuts through training, cut plans, and reuse programs. By connecting design, procurement, and field feedback, builders cut costs, improve sustainability, and boost operational efficiency across projects.

How Much Waste Comes from Moulding and Trim in Home Building?

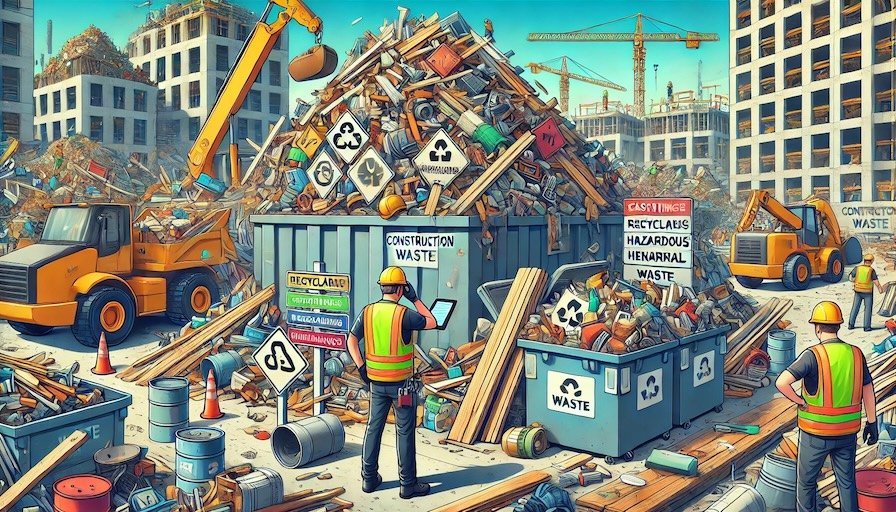

The construction and demolition (C&D) industry generates over 600 million tons of waste annually—nearly double that of municipal solid waste. While moulding and trim represent only a small percentage of total building materials by volume, they are frequently overrepresented in site waste streams.

Why? These materials are often overordered, damaged during storage or transit, or rendered unusable due to design changes or poor coordination. Additionally, trim components—because of their custom sizing, finishes, and installation requirements—are more sensitive to deviations in planning and field execution than bulk materials like framing lumber or drywall.

Field studies and audits from residential developments show that 10–15% of moulding and trim materials are discarded unused, either as cutoffs, surplus, or mishandled pieces. This waste doesn’t just increase disposal costs—it also ties up storage space, inflates procurement budgets, and reflects inefficiencies in estimation, coordination, and execution.What Causes Waste in Moulding and Trim Procurement?

Several common issues are responsible for procurement waste:

- Overordering: Builders often add a buffer to avoid shortages, but without precise controls, this leads to excessive leftovers.

- Measurement Errors: Manual takeoffs can produce inaccurate quantities, especially in complex interiors or when architectural drawings lack clarity.

- Design Changes: Last-minute plan adjustments can make already-ordered materials obsolete or incompatible.

- Transportation Damage: Improperly packaged trim is easily dented, chipped, or warped during long-distance delivery.

- Lack of Standardization: Custom or irregular trim profiles limit interchangeability between housing units and make leftovers unusable on future jobs.

These inefficiencies are usually not the result of one mistake, but the accumulation of small breakdowns in the supply chain, communication, and field practices.

How to Reduce Waste in the Construction Industry?

Waste reduction in trim procurement starts with planning and accountability:

- Project-Specific Estimation: Every home design is different. Builders must calculate moulding quantities based on actual layouts and not reuse old estimates.

- Standardized Profiles: Using consistent trim designs across multiple units makes procurement easier, reduces variety, and allows for reuse.

- Jobsite Storage and Protection: Moisture, dirt, and stacking pressure can damage mouldings if not stored correctly.

- Supplier Communication: Clarify product dimensions, finishes, and delivery timelines to avoid misorders or delays.

- Onsite Waste Reviews: Auditing trim waste regularly can help identify patterns of overuse, mishandling, or design inefficiency.

Planning trim procurement should be treated with the same level of rigor as framing or mechanical components—because the waste cost is just as real.

What Causes Waste in Moulding and Trim Procurement?

Procurement waste in moulding and trim is typically the result of a disjointed workflow between design, estimation, procurement, and field installation. Unlike standard framing components, trim is highly variable in style, dimensions, and finish, which introduces multiple opportunities for error.

Here are the most common and systemic causes:

- Overordering Without Historical Data: Many builders apply arbitrary waste factors—10%, 15%, or more—without analyzing actual usage data from previous projects.

- Inaccurate Takeoffs and Scope Creep: Incomplete architectural drawings or scope changes during construction lead to mismatched quantities and unused profiles.

- Design Fragmentation: When multiple trim styles are specified across rooms or units, procurement becomes fragmented, and surplus increases.

- Jobsite Handling Errors: Trim is often stored on uneven surfaces or exposed to weather, leading to warping, chipping, or staining before installation.

- Supply Chain Gaps: Delays or substitutions from suppliers can lead to rush ordering, duplication, or incompatibility with other components.

Most of this waste is preventable with a closed-loop procurement process—one that connects digital estimation, centralized ordering, real-time inventory tracking, and field feedback. Unfortunately, many residential projects still rely on siloed communication, which allows small errors to scale into significant material loss.

Which Technique Is Most Effective for Reducing On-Site Waste?

The most effective technique for reducing trim and moulding waste on-site is standardization, paired with schedule-aligned delivery and controlled installation workflows. When builders use consistent trim profiles across house models, procurement becomes more streamlined, and material forecasting is far more accurate. Coordinating deliveries with actual installation phases also prevents premature site exposure that leads to physical damage.

Here are additional techniques with proven results:

- Pre-assemble Trim Kits: Package mouldings per unit or model to reduce on-site sorting and missing components.

- Limit Trim Variants: Standardize profiles and dimensions across the project to simplify both procurement and installation.

- Provide Cut Plans: Give installers visual guides and cut optimization charts to reduce offcuts.

- Use Offcut Bins Strategically: Collect usable offcuts and sort by type for reuse in closets, utility rooms, or other units.

Waste reduction isn’t a one-time fix. It’s a repeatable process—anchored by consistent design, coordinated field execution, and responsive feedback loops.

How Can Builders Optimize Trim and Moulding Orders Without Overbuying?

Overordering remains one of the most persistent sources of waste in trim procurement. To avoid it, builders must shift toward a data-driven procurement process supported by continuous feedback and order reconciliation. Here’s what works:

- Use Actual Build Data: Monitor trim usage across past projects to develop model-specific quantity benchmarks.

- Plan for Minimal Overage: Limit overage to 3–5%, based on real field loss rates. A small supplemental order is cheaper than hundreds of feet of surplus.

- Audit and Adjust: Compare estimated vs. installed quantities post-project, and adjust procurement algorithms accordingly.

- Coordinate with Installers: Gather field feedback on poor fit, frequent recuts, and profile inconsistencies that lead to waste.

When builders treat procurement as a predictive process—rather than guesswork—waste drops, and project profitability improves.

How Can Field Teams Reduce Procurement-Related Waste?

No procurement strategy succeeds without strong field execution. Even well-ordered materials can become waste due to improper handling, poor communication, or sequencing errors. Here’s how site teams can significantly reduce trim-related waste:

- Protect Materials Onsite: Store mouldings elevated off the ground, away from high-traffic zones, and shielded from moisture or UV exposure.

- Train for Smart Cutting: Provide training in measurement accuracy and optimized cut patterns to minimize offcuts.

- Designate a Trim Lead: Assign a team member to manage trim inventory, track offcuts, and flag issues early.

- Improve Trade Communication: Ensure foremen, carpenters, and procurement teams are aligned on trim profiles, quantities, and usage plans.

By treating finish materials with the same discipline as structural components, site crews become integral partners in eliminating avoidable waste.

Where Do Construction Waste Materials Go After Disposal?

When not properly reused, repurposed, or recycled, excess trim and moulding materials are typically sent to construction and demolition (C&D) landfills. These facilities accept a wide range of waste—from wood offcuts and packaging to fully unused materials discarded due to overordering or design changes.

The issue isn’t just landfill space—it’s environmental impact. Treated or painted mouldings can contain adhesives, resins, or VOCs that persist in soil and groundwater. In many jurisdictions, C&D waste is subject to regulatory oversight due to its potential to harm ecosystems if unmanaged.

Fortunately, several practical alternatives exist:

- Donation Programs: Nonprofits and reuse centers often accept surplus moulding in good condition for redistribution in affordable housing projects.

- Material Exchange Networks: Builders can use local platforms or online directories to trade or sell unused stock to nearby contractors.

- Onsite Waste Segregation: On larger builds, contractors may deploy waste sorting bins or partner with services to divert wood waste from landfill to recycling.

Disposal should be treated as the final option—not the default. With better planning and coordination, a large portion of trim waste can be diverted from landfills and put to beneficial use.

Conclusion

Reducing waste in moulding and trim procurement isn’t just a cost-saving measure—it’s a mark of operational excellence. By implementing accurate estimating, standardizing product use, improving site practices, and prioritizing collaboration between design, procurement, and field teams, home builders can significantly cut waste without sacrificing quality or schedule.

This isn’t about adopting complex new technologies. It’s about tightening the process, empowering teams, and closing the loop between material planning and material use.

Builders who take ownership of this challenge not only improve profitability—they lead the industry toward more sustainable and efficient construction practices.