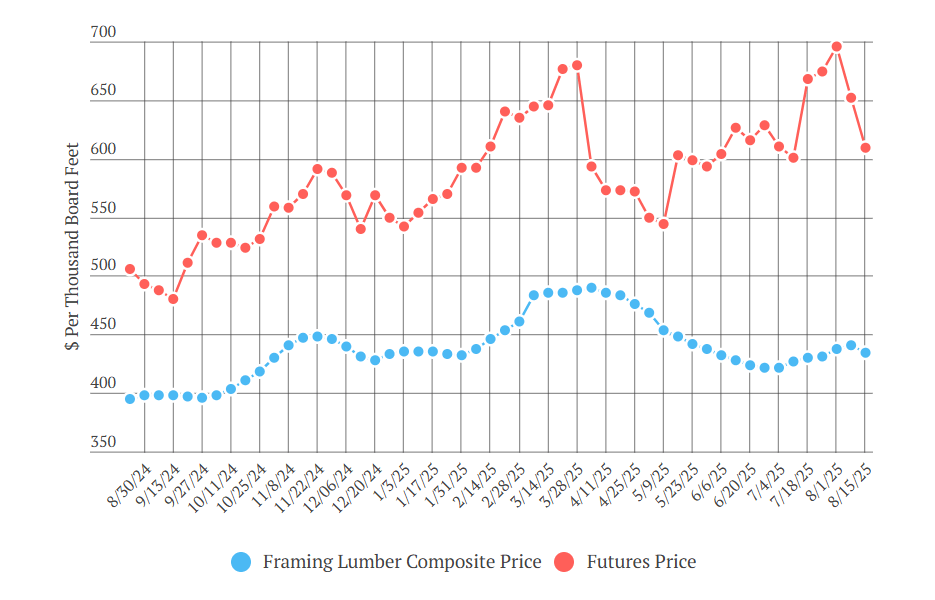

The construction industry is under mounting pressure from rising lumber costs. According to the latest data from the National Association of Home Builders (NAHB), as of August 15, 2025, U.S. framing lumber prices climbed 1.6% month-over-month and 11.6% year-over-year. Softwood lumber followed a similar trend, up 0.9% in the past month and 11.6% higher than a year ago. These increases are driven by a mix of challenges—supply chain disruptions, labor shortages, stronger demand, and policy shifts such as higher import tariffs. For builders and contractors, the question is clear: how can you keep projects on budget without lowering quality standards? In this article, we’ll explore cost-effective wood material solutions that strike the right balance between performance and affordability.

Why Lumber Prices Are Increasing

Lumber prices have fluctuated significantly in recent years. According to NAHB, the main reasons include rising demand, higher tariffs, supply chain bottlenecks, and insufficient domestic production. On August 8, 2025, the U.S. Department of Commerce raised the countervailing duty rate on Canadian softwood lumber imports from 6.74% to 14.63%. Combined with the existing 20.6% anti-dumping duty, the total tariff now stands at 35.2%—far higher than the previous 14.4%. This has substantially increased the cost of importing lumber from Canada.

In addition to this, labor shortages and transportation challenges have exacerbated the situation. The COVID-19 pandemic significantly disrupted lumber mills and global supply chains, making it more difficult for manufacturers to meet growing demand. Environmental regulations have also limited logging activities, further restricting the supply of raw timber.

These factors combined have created an environment of uncertainty, with prices for traditional lumber remaining volatile. As a result, builders and contractors need to find alternative, cost-effective wood material solutions to stay competitive and manage costs effectively.

The Importance of Finding Cost-Effective Wood Material Solutions

For builders and contractors, managing material costs is essential to keeping projects on budget and competitive. If lumber prices continue to rise, exploring alternative materials can help maintain profitability without sacrificing quality. By switching to engineered wood products or other materials, builders can reduce exposure to price fluctuations and ensure more predictable costs.

In addition to saving money, choosing the right materials can also reduce waste, improve efficiency, and contribute to more sustainable building practices—considerations that are increasingly important in modern construction.

Alternative Wood Material Solutions: LVL, MDF

When considering alternatives to traditional lumber, several innovative wood products offer both cost savings and high performance:

- Laminated Veneer Lumber (LVL): LVL is an engineered wood product made by bonding layers of wood veneer with adhesive. It offers superior strength and is commonly used for beams, headers, and studs. LVL is often more cost-effective than dimensional lumber, thanks to its uniformity and manufacturing process. Builders appreciate its consistency, reduced material waste, and high strength-to-weight ratio.

- Medium Density Fiberboard (MDF): MDF is created by breaking down wood fibers into fine particles, which are then pressed into boards. While not suitable for structural applications, MDF is an excellent alternative for non-structural uses like cabinetry, moldings, and interior paneling. It provides a smooth, even surface for painting and finishing, making it an affordable option for aesthetic components in high-volume residential or commercial projects.

Both LVL and MDF present opportunities for cost savings while maintaining performance, making them excellent choices depending on the scope and nature of a project.

How Builders and Contractors Can Save on Wood Materials

To save on wood materials, builders and contractors can take several practical steps:

- Bulk Purchasing: Buying in bulk from wholesalers can significantly reduce the cost per unit, especially for engineered wood products like LVL and MDF, which tend to have more stable pricing compared to traditional lumber.

- Optimizing Material Usage: Careful project planning and material management can minimize waste. By accurately estimating material needs and using digital tools for tracking and ordering, contractors can avoid over-purchasing and reduce excess material costs.

- Exploring Regional Suppliers: Lumber prices vary by region, depending on local availability and transport costs. Sourcing materials from regional suppliers can help reduce overall expenses and mitigate the impact of high import taxes.

- Leveraging Trade Relationships: Building strong relationships with suppliers can result in better pricing, priority access to materials, and the ability to negotiate favorable terms during periods of high demand.

Long-Term Benefits of Switching to Cost-Effective Materials

Switching to cost-effective materials like LVL and MDF offers several long-term advantages for builders and contractors:

- Increased Profit Margins: Reducing material costs improves profit margins, allowing builders to reinvest in the business or absorb unexpected price fluctuations without impacting profitability.

- Sustainability: Many engineered wood products are made from sustainably sourced or recycled materials, which can appeal to clients looking for environmentally responsible construction solutions.

- Adaptability: As lumber prices continue to fluctuate, the ability to adapt and incorporate alternative materials gives builders a competitive edge, ensuring they can weather price volatility without sacrificing project quality.

- Client Satisfaction: Delivering high-quality projects on time and within budget fosters trust with clients, which can lead to repeat business, positive reviews, and referrals.

Summary

While rising lumber prices, including the impact of increased import taxes, pose significant challenges, there are plenty of opportunities to offset these costs. By adopting alternative wood materials like LVL and MDF, optimizing material usage, and leveraging strategic supplier relationships, builders and contractors can maintain quality, stay within budget, and ensure long-term success in an increasingly unpredictable market.