Leading Paragraph

When designing or installing a Shaker door, the panel thickness directly affects strength, stability, and design proportion. Many builders wonder: how thick should a Shaker door be to meet modern standards? Let’s break down the typical thickness, why it matters, and how custom options work for different projects.

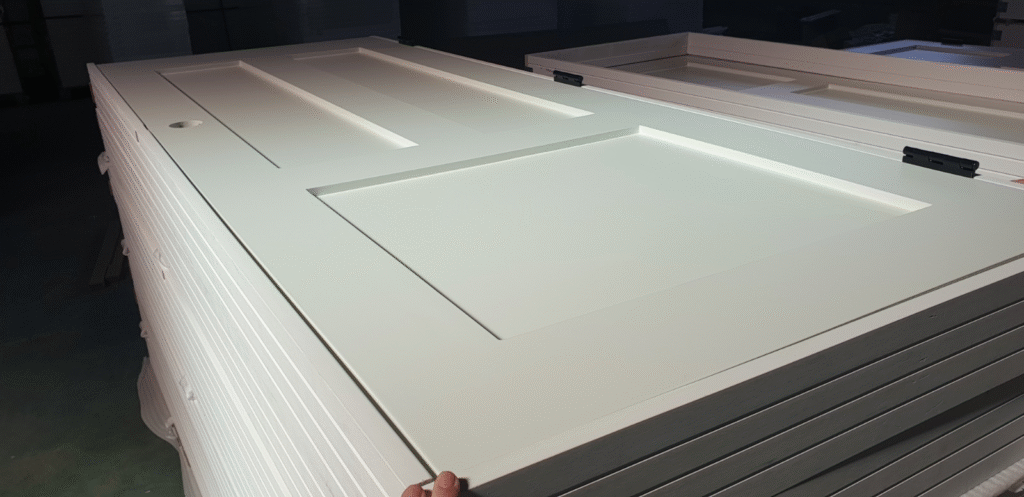

The standard Shaker door is 1 3/8 inches thick, featuring a 1/4-inch recessed center panel with 3 1/4-inch stiles and rails. This traditional construction keeps the door lightweight yet strong, maintaining that signature Shaker simplicity. For taller or wider doors, builders may increase overall thickness to 1 3/4 inches to ensure durability and prevent warping. Custom doors can adjust panel depth and frame width based on architectural style or soundproofing needs.

What Is the Standard Thickness for a Shaker Door?

Most Shaker interior doors follow the 1 3/8-inch (35 mm) industry standard — the same used in most U.S. residential buildings. This thickness strikes a perfect balance: it’s heavy enough to feel solid but light enough for standard hinges and handles.

If you’re building a door for high-traffic areas or commercial use, upgrading to 1 3/4 inches (44 mm) improves acoustic insulation and longevity.

How Thick Should the Center Panel Be?

The center panel gives the Shaker door its iconic recessed look. Traditionally, the center panel measures about 1/4 inch thick, set slightly behind the frame to create the signature square edge. In modern variations, MDF or veneered wood panels may reach 3/8 inch to add weight and stability.

Always allow the panel a small floating gap (around 1/8 inch) inside the frame to handle wood expansion from humidity.#)

What Are the Typical Frame Dimensions?

The Shaker frame, composed of stiles and rails, typically measures:

- Width: 2 1/4 to 3 1/4 inches

- Thickness: Same as the overall door (usually 1 3/8 inches) This proportion gives the door its balanced, minimalistic look. Slim Shaker designs use narrower frames (around 2 inches) for a modern, streamlined appearance.

When Should You Choose Custom Thickness?

Custom thickness options are ideal when:

- Matching historic homes that originally used thicker doors (up to 2 inches).

- Designing soundproof rooms or offices where additional mass improves acoustic control.

- Creating oversized double doors or barn-style Shaker doors where extra rigidity prevents bowing.

Custom shops can tailor thickness from 1 1/4 to 2 inches, depending on the frame profile and hinge strength.

What Materials Affect Thickness Choices?

Material choice impacts both the appearance and weight of a Shaker door:

- Solid wood (oak, maple, pine): Classic look, natural feel, slightly heavier — best at 1 3/8 to 1 3/4 inches.

- MDF: Uniform density, ideal for painted Shaker doors; can be thinner (1 1/4 inch) without compromising strength.

- Veneered composite cores: Used in premium Shaker designs, combining lightweight build with durability.

Selecting the right material helps maintain consistent edge profiles and hinge performance.

How Does Thickness Affect Performance and Style?

Thicker doors offer better sound insulation, rigidity, and high-end feel, but they also require stronger hinges and deeper jambs. Thinner doors are lighter, easier to install, and cost-effective — ideal for internal passageways. For visual harmony, match the door thickness to the room’s architectural scale and trim design.

Custom Shaker Door Options Near Me

For builders or homeowners searching “Shaker door panel thickness standard sizes custom options near me,” local manufacturers often provide made-to-order solutions. They allow customization of:

- Overall door thickness (1 1/4″–2″)

- Panel depth (1/4″–3/8″)

- Frame width and edge profile

When ordering, specify the exact jamb depth and hinge type to ensure smooth installation.

Summary

The standard Shaker door measures 1 3/8 inches thick with a 1/4-inch recessed center panel, delivering timeless simplicity and strength. For heavy-duty, soundproof, or custom applications, increasing thickness to 1 3/4 inches offers superior performance — blending craftsmanship, proportion, and durability in every build.