Across countless residential and commercial projects in North America, the Shaker door has become one of the most frequently specified options. Builders and wholesalers encounter it everywhere — from large multi-family developments to single-family renovations. But what exactly is a Shaker door, and why does it remain such a popular choice among architects, contractors, and distributors?

What Is the Structural Design Behind a Shaker Door?

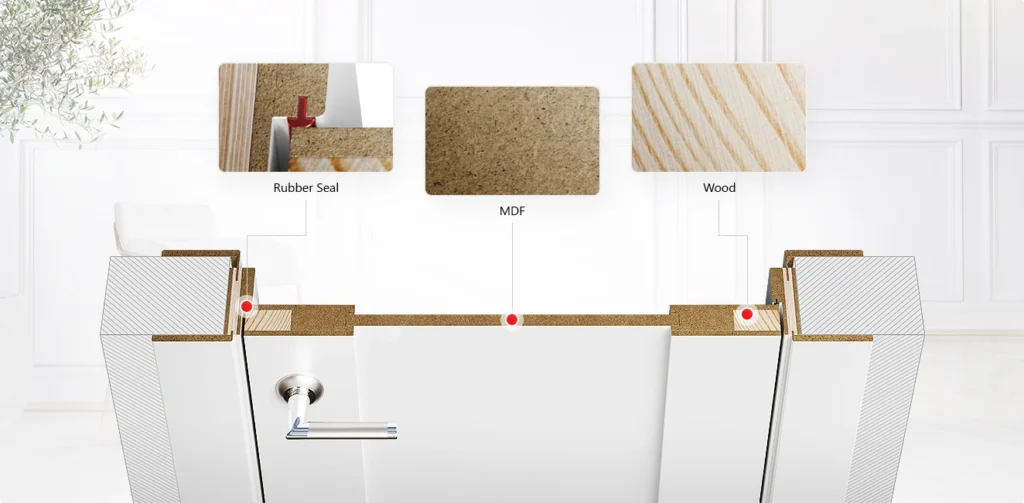

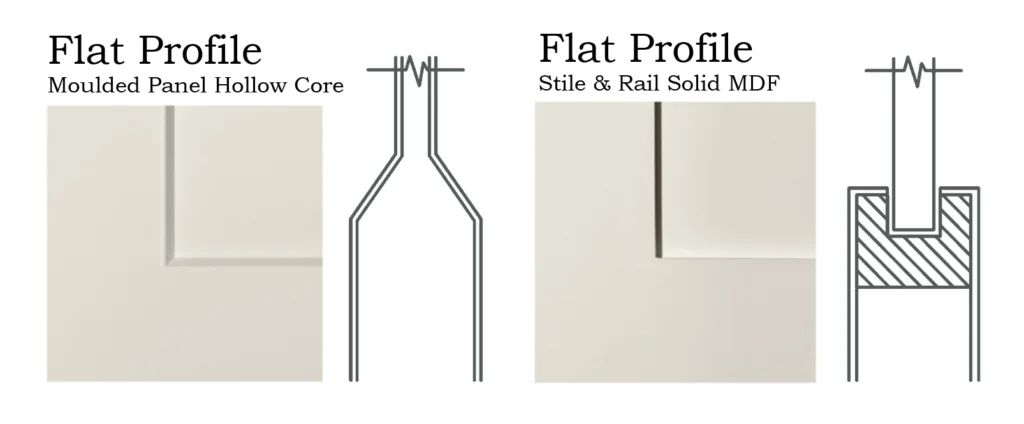

A true Shaker door is made of five key components: two vertical stiles, two horizontal rails, and a recessed center panel. This five-piece frame-and-panel construction gives the door both strength and flexibility. Unlike solid slab doors, the panel inside a Shaker door can expand or contract slightly without affecting the integrity of the outer frame—making it more resistant to warping and cracking over time.

This structural simplicity is one of the biggest reasons why builders and manufacturers favor Shaker doors. The components are easy to machine, easy to assemble, and compatible with a wide range of materials, including MDF, solid wood, and engineered wood cores. For wholesalers, this means consistent quality across batches. For builders, it means fewer installation issues and better long-term performance—especially in climate-variable regions across North America.

Shaker doors also allow for slight customization without altering the basic structure. You can adjust the rail and stile width, use square edges, or apply different finishes—while still retaining the durability and cost-efficiency of the five-piece construction.

In addition, the center panel thickness can also be customized: 8mm or 12mm.

- For an 80-inch door with 45mm thickness, the center panel is 12mm.

- For a 96-inch door, the center panel is always 12mm, regardless of whether the door is 35mm or 45mm thick, unless otherwise specified.

That makes it an ideal solution for both budget-conscious and design-driven projects.

Shaker Door Panels: Style Meets Function

What truly defines the look of a Shaker door is its center panel. Far from being just a filler, the panel controls both the door’s aesthetics and performance. By varying its thickness and layout, builders can adapt one core structure to match different project needs—from budget-friendly apartments to high-end custom homes.

Best-Selling Panel Styles

- 1-Panel Shaker – The timeless minimalist design, widely used in contemporary interiors.

- 2-Panel Shaker – Balanced proportions, making it a top pick for bedrooms and family spaces.

- 3-Panel Shaker – A versatile option that bridges modern and transitional styles.

- 5-Panel Horizontal Shaker – Clean horizontal lines that add a distinctly modern character.

With these panel variations, Shaker doors deliver the perfect balance of design flexibility, durability, and cost-efficiency, making them the go-to choice for more than 90% of North American projects.

Shaker vs Traditional Door Styles: Which Works Better for Modern Builders?

1. Installation and Labor Efficiency

Shaker doors are easier and faster to install due to their clean, square design and lightweight construction. Traditional raised-panel doors, especially those with intricate molding or contouring, often require more careful alignment and longer finishing time. For builders managing multiple units or tight schedules, the labor savings with Shaker doors can be significant.

2. Material and Manufacturing Costs

Shaker doors typically use less material and require fewer production steps than traditional raised-panel doors. The simple five-piece structure is easy to mass-produce, whether using MDF, hardwood, or composite cores. Traditional doors often involve more carving or milling, increasing both time and cost. From a wholesale perspective, Shaker styles offer better margin control and more competitive pricing in high-volume orders.

3. Design Flexibility and Customer Appeal

While traditional doors appeal to homeowners seeking ornate, classic aesthetics, their style can limit interior design choices. Shaker doors, on the other hand, adapt easily to modern, transitional, and farmhouse styles. Their neutral appearance gives buyers more flexibility in color, hardware, and overall room design. Builders often prefer Shaker doors because they satisfy a broader customer base without requiring constant product variation.

4. Maintenance and Durability

With fewer grooves and edges, Shaker doors are easier to clean and less prone to accumulating dust or moisture-related damage. Traditional doors with deep panels and decorative profiles may require more upkeep, especially in kitchens, bathrooms, or humid environments. Shaker’s simple form also means fewer surface cracks and paint failures over time, which reduces warranty claims and service callbacks.

5. Inventory and Supply Chain Simplicity

For wholesalers, stocking traditional doors in various styles, profiles, and finishes adds complexity. Shaker doors simplify logistics. One base design can serve multiple markets with just a change in finish or dimension. Builders benefit from reduced lead times and easier procurement for repeat projects.

Conclusion

While traditional door styles still have their place in high-end or historically styled homes, Shaker doors are clearly better suited for modern builders focused on scalability, efficiency, and wide customer acceptance. Their structure supports mass production, flexible application, and long-term performance—making them a practical choice across most North American projects.

Shaker vs Traditional Door Styles: Which Works Better for Modern Builders?

1. Installation and Labor Efficiency

Shaker doors are straightforward to install thanks to their simple, square-edge design. With flat panels and minimal detailing, they require less precision during alignment and can be painted or prefinished quickly. In contrast, traditional doors with raised panels, intricate edges, or curved moldings often demand more time, skill, and labor—especially when on-site adjustments or touch-ups are needed. For modern builders working under tight deadlines, faster installation means better efficiency and lower labor costs.

2. Manufacturing and Material Cost

The clean structure of Shaker doors makes them easier and cheaper to produce in volume. They consist of five components that are easy to cut, assemble, and standardize—ideal for mass production using MDF, engineered wood, or even solid wood. Traditional doors, however, often require additional machining and more material for complex profiles and raised panels. This increases the production cost and extends lead times—something builders want to avoid in fast-paced projects.

3. Design Flexibility and Market Appeal

Shaker doors offer unmatched versatility. Their minimalist aesthetic adapts effortlessly to various design styles—modern, transitional, farmhouse, or even coastal. By changing the finish, color, or hardware, the same door design can serve multiple purposes. Traditional doors, while elegant, tend to have a fixed stylistic identity that may not appeal to all buyers. Builders seeking broad market acceptance often prefer Shaker styles because they offer a timeless, neutral canvas that works in nearly any home.

4. Maintenance and Long-Term Performance

Shaker doors are easier to clean and maintain. With flat panels and fewer grooves, they collect less dust and are less likely to experience paint chipping or moisture buildup. Traditional doors with deeper recesses and decorative molding are more vulnerable to cracking, warping, and finish wear—especially in high-humidity environments like bathrooms or kitchens. For builders who want to reduce post-sale callbacks or warranty claims, Shaker doors provide better long-term durability.

5. Inventory Simplicity for Wholesalers and Builders

From a supply chain perspective, Shaker doors are much easier to stock, finish, and distribute. One profile, with slight variations in size and finish, can serve an entire project or multiple developments. Traditional styles often require multiple SKUs to meet different design expectations, complicating purchasing and inventory management. For both builders and wholesalers, less complexity means smoother operations and fewer delays.

Conclusion

While traditional door styles still have value in luxury or historically themed projects, Shaker doors are better suited to the realities of modern construction. Their straightforward design, low maintenance, faster installation, and broad customer appeal make them the practical, scalable solution for today’s builders and wholesalers. In most cases, the simplicity of Shaker doors isn’t a limitation—it’s a strategic advantage.

Summary

The reason Shaker doors work for 90% of North American projects comes down to three things: structure, simplicity, and scalability. Their five-piece design is engineered for durability, easy manufacturing, and faster installation—qualities that directly benefit both builders and wholesalers. Whether the project leans modern, transitional, or traditional, Shaker doors adapt with minimal effort and maximum return. In a market where efficiency, consistency, and versatility are non-negotiable, the Shaker door remains a proven standard—and often, the smartest choice.