Selecting the right type of interior door impacts far more than appearance—it affects sound control, installation time, durability, and overall build quality. For builders and wholesalers managing scale and performance expectations, the choice between solid core and hollow core doors requires careful evaluation.

Which door type offers the best balance of performance, cost-efficiency, and long-term value for your project?

Solid core doors deliver superior acoustic control, durability, and perceived quality—making them ideal for higher-end or high-traffic applications. Hollow core doors are lightweight, faster to install, and cost-effective, well-suited for bulk installations and budget-sensitive projects. Choosing the right door type depends on where performance matters most in your build.

What Is the Difference Between Solid Core and Hollow Core Doors?

When comparing solid core and hollow core doors, it’s not just about the weight or price—it’s about what’s inside, and how that affects long-term performance on-site.

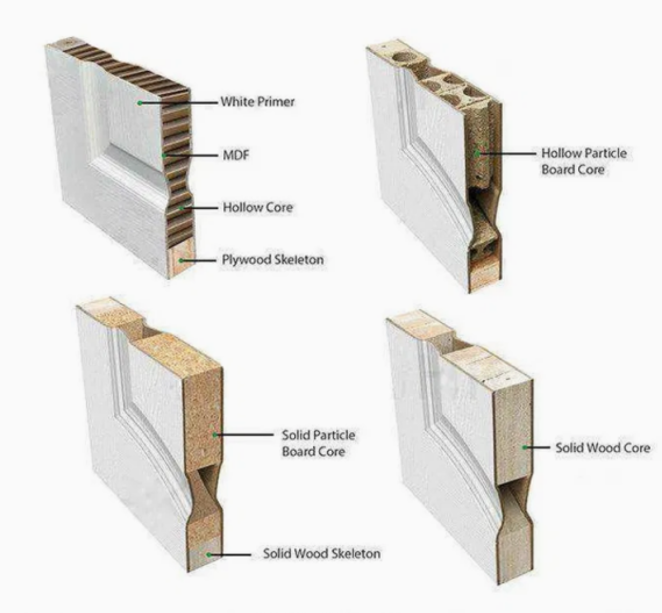

Solid core doors are constructed with a dense interior fill that gives them strength, heft, and acoustic mass. Common fill types include:

- MDF (Medium-Density Fiberboard) – a dense engineered wood offering sound resistance and a smooth finish.

- Particleboard or Tubular particleboard – often used in molded solid doors for residential use.

- Laminated Veneer Lumber (LVL) – layered wood for added structural strength, often in commercial or heavy-use environments.

- Polyurethane foam – occasionally used in lighter solid doors where weight control is important.

Hollow core doors, on the other hand, are built with a wooden frame and a lightweight filler. Typical fillers include:

- Honeycomb cardboard – widely used for economy doors, lightweight but fragile.

- Steel or composite frame with minimal infill – used in some commercial-grade prehung doors, balancing strength and affordability.

While both door types are skinned with similar outer materials like HDF or veneer, the difference in core dramatically affects how the door feels, performs, and ages.

Solid Core vs Hollow Core: Key Performance Differences

Let’s go beyond the specs and look at how each door type performs where it really matters—on the job site and after handover.

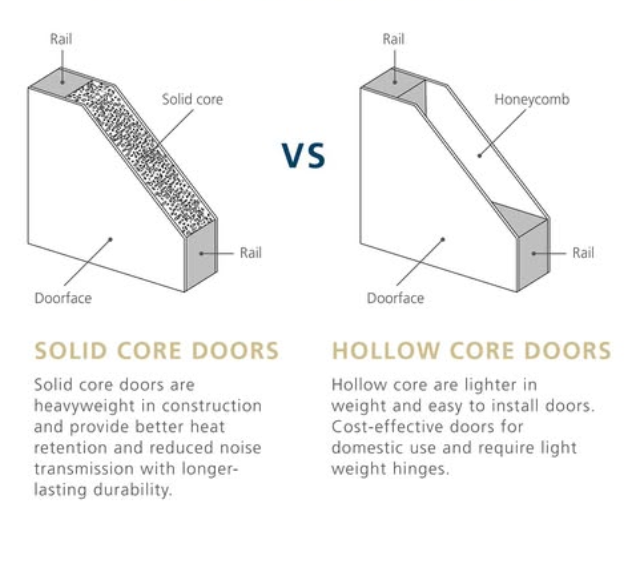

- Durability: Solid core doors resist dents, slams, and wear from high foot traffic. They maintain their appearance and structural integrity longer. Hollow core doors, in contrast, are more vulnerable to everyday knocks or accidental punctures.

- Sound Control: If privacy is a concern—like in bedrooms, offices, or multi-family units—solid core is the clear winner. Its dense core blocks more sound and creates a higher-end feel. Hollow doors let sound pass easily, often compromising acoustic performance.

- Moisture and Climate Resistance: Solid core doors handle climate variations better when sealed properly. Hollow core doors are more prone to swelling, warping, or delamination, especially in humid environments.

- Installation & Handling: Hollow core doors are lighter and faster to install, ideal for fast-track builds or single-person handling. Solid core doors may require extra labor and stronger hardware due to their weight—but that comes with added performance.

- Repairability: A solid core door can be patched, veneered, or sanded and refinished. If a hollow door is punctured, it often needs full replacement because there’s no core material to support a repair.

- Cost vs. Value: While hollow core saves money upfront, solid core often pays off over time—fewer replacements, better end-user satisfaction, and stronger perceived quality in the building.

Choose solid core when you need performance. Choose hollow core when you need volume and speed.

For wholesalers supplying diverse projects, keeping both types in your catalog ensures you can meet both budget-driven and quality-driven demand.

Cost and Supply Chain Considerations

The price gap between solid and hollow core doors is more than just a matter of material cost—it affects everything from installation time to storage logistics and long-term value.

- Hollow core doors typically cost $30–80 per unit, making them suitable for large-scale projects where speed and unit cost are priorities—such as budget apartments or temporary commercial builds.

- Solid core doors range from $120–300 per unit, depending on finish and specifications. While they have a higher upfront price, their performance and longevity often result in a lower total cost of ownership over time.

Beyond material cost, wholesalers and project managers should factor in:

- Labor: Hollow core doors are easier to handle and install. Solid doors may require reinforced frames and more installation time, especially in multi-story buildings.

- Hardware: Solid core installations typically need heavier-duty hinges and closers, slightly increasing hardware budgets.

- Service life: Solid doors hold up better to traffic, impact, and finish wear—resulting in fewer replacements over a building’s lifecycle.

Packaging, Transport & Site Delivery: What Wholesalers Must Plan For

Shipping and storage are important for large-scale door procurement:

- Solid core doors are heavier and may require two-person lifting or equipment assistance during delivery, especially for retrofit or high-rise projects.

- Hollow core doors are lighter and easier to handle, offering smoother logistics and faster on-site placement.

From a wholesaler’s perspective, hollow core doors maximize handling efficiency, while solid core doors justify extra effort with superior user experience and longer service life.

Maintenance and Lifecycle Performance

For builders and facility owners alike, long-term maintenance plays a key role in selecting door types:

- Hollow core doors are difficult to repair once damaged. Dents or punctures often mean full replacement, especially when the thin surface or honeycomb core is compromised.

- Solid core doors, in contrast, can be refinished, patched, or resurfaced to extend their usability. Veneer touch-ups, edge repairs, and repainting are all viable—especially valuable in commercial or high-traffic areas.

This makes solid core a smarter choice in environments with higher wear-and-tear expectations, and where maintenance budgets are a factor.

Which Door Works Best for Which Project?

Matching the right door type to the right project is essential for balancing cost, function, and aesthetics. Below is a simplified guide for decision-making:

| Project Type | Recommended Door Type | Reason |

|---|---|---|

| Budget Apartments | Hollow Core | Cost-effective, fast to install, meets basic standards |

| Mid- to High-End Homes | Solid Core | Soundproofing, premium feel, better resale value |

| Hotels & Hospitality | Solid Core | Privacy, impact resistance, long-term performance |

| Schools / Institutions | Solid Core | More durable in heavy-use settings |

| Commercial Offices | Mixed (by room function) | Solid for key areas; hollow for storage and utility |

| Rental Renovations | Hollow Core | Lower upfront cost for quick turnover |

Tip: Use solid core doors wherever end-user experience, longevity, and acoustic privacy are priorities. Use hollow core where speed and unit cost matter most.

Conlusion

Solid core and hollow core doors serve distinct roles across different project types. Neither is inherently better—the key is aligning performance with purpose.

For residential upgrades, large-scale housing, or tenant turnovers, hollow core offers speed and affordability. For offices, hotels, institutional projects, and premium builds, solid core provides better acoustics, longevity, and end-user experience.

For construction professionals and wholesale buyers, understanding this tradeoff supports better material planning, smoother installations, and fewer post-handover issues.