Ordering custom cabinets may seem straightforward, until small oversights turn into costly delays, budget overruns, or unhappy clients. Because custom cabinetry is built strictly to specification, even minor mistakes can lead to redesigns, reorders, or on-site installation conflicts that disrupt the entire project timeline.

The most common issues builders face when ordering custom cabinets fall into five key areas: incomplete or incorrect measurements, overlooking appliance specifications, choosing style over everyday function, underestimating production and logistics timelines, and failing to clearly define what’s included in the order. Any one of these missteps can result in expensive corrections and unnecessary stress.

In the sections below, we’ll break down each of these mistakes in detail and share practical tips to help you avoid them,saving time, money, and frustration on your next build.

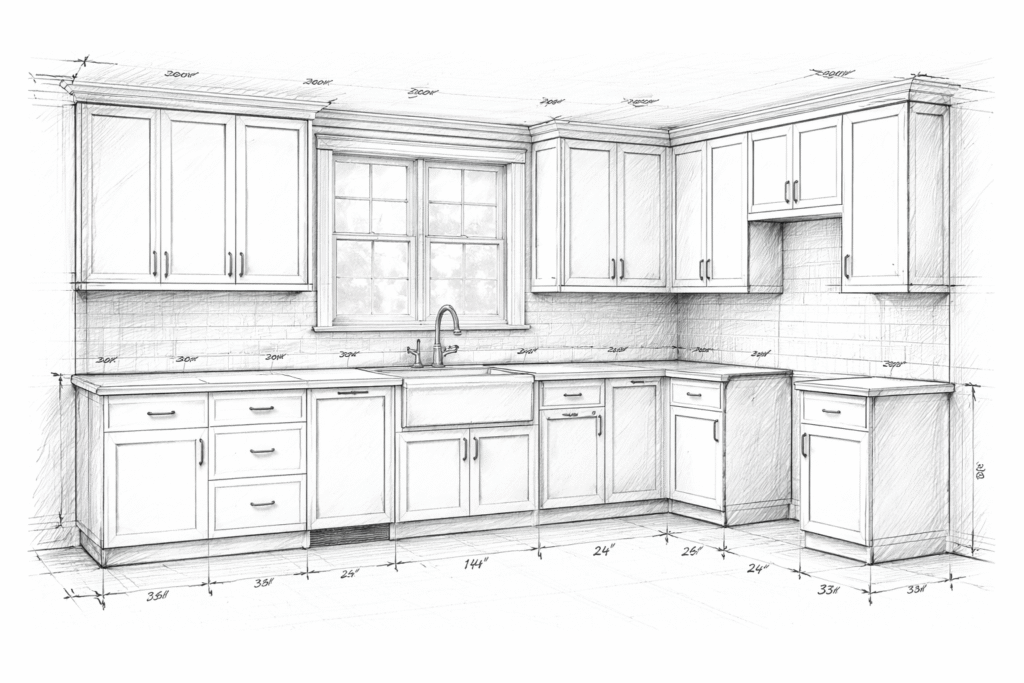

Mistake #1: Incomplete or Incorrect Measurements

This is the most common cabinet ordering mistake and often the hardest to fix once production begins. Even a quarter-inch error can prevent custom cabinets from fitting properly, forcing costly reorders or on-site modifications. Because custom cabinets are built strictly to approved specifications, any measurement issue left uncorrected will carry through to installation.

Builders sometimes rely on rough plans or outdated dimensions without fully verifying final site conditions. Common oversights include failing to account for ceiling height variations, uneven walls or floors, baseboard thickness, and surrounding architectural features such as soffits, window trim, or wall returns. Plumbing and electrical locations are also frequently underestimated, creating conflicts during installation.

To avoid this mistake, always measure after drywall and flooring are complete, and use precise tools such as a laser measure. Double-check all critical dimensions—height, width, depth, and clearances—and review them carefully during the shop drawing approval stage. Slowing down during measurement is one of the simplest ways to prevent major delays and unnecessary costs later in the project.

Mistake #2: Ignoring Appliance Specifications

Another frequent mistake builders make is ordering custom cabinets before finalizing appliance specifications. While appliances may seem standardized, sizes, ventilation requirements, and clearance tolerances can vary significantly between brands and models. Assuming “standard dimensions” often leads to cabinets that don’t align with the actual appliances chosen.

Common issues include insufficient clearance for built-in refrigerators, dishwashers that don’t sit flush, or range hoods that conflict with upper cabinets. Even small differences in appliance depth or hinge swing can affect cabinet layout and door operation. Once cabinets are in production, correcting these issues usually means redesigning panels, cutting cabinets on site, or delaying installation while replacements are ordered.

To avoid this mistake, all appliance models should be selected and confirmed before shop drawings are finalized. Always provide appliance specification sheets to your cabinet supplier and verify required clearances during the drawing review process. Coordinating cabinetry and appliances upfront ensures a cleaner installation, better functionality, and fewer last-minute surprises on site.

Mistake #3: Choosing Style Over Function

Focusing too heavily on appearance while overlooking everyday functionality is another common mistake when ordering custom cabinets. While door styles, finishes, and hardware play a major role in visual appeal, cabinets must ultimately support how the space will be used. A design that looks great on paper can quickly become frustrating in daily use if functionality isn’t properly considered.

Builders often encounter issues such as drawers that are too shallow for storage needs, corner cabinets that are difficult to access, or door styles and hardware that interfere with appliance clearance and workflow. In some cases, high-end aesthetic choices may not align with the project’s purpose, especially in rental properties or resale-focused builds where durability and ease of use matter more than custom detailing.

To avoid this mistake, cabinet layouts should be designed around the end user, not just the look. Consider storage needs, traffic flow, and frequency of use when selecting cabinet configurations and accessories. Balancing style with function leads to kitchens that not only photograph well, but also perform efficiently and satisfy clients long after installation.

Mistake #4: Underestimating Lead Time & Logistics

Many builders underestimate how long custom cabinets actually take from approval to installation. Unlike stock cabinetry, custom cabinets require time for final drawings, production, finishing, quality checks, and transportation. Failing to factor in these steps can throw off the entire project schedule.

Common issues include assuming factory lead times are fixed year-round, overlooking peak seasons, holidays, or material shortages, and not accounting for shipping, customs clearance, and local delivery time. As a result, cabinets may arrive weeks later than expected, delaying countertop installation, appliance fitting, and final inspections.

To avoid this mistake, cabinet specifications should be finalized as early as possible, and realistic lead times should be confirmed with the supplier before construction schedules are locked in. Building buffer time into the project plan and maintaining clear communication with your cabinet partner can help prevent costly delays and keep the job moving forward.

Mistake #5: Not Clarifying What’s Included

One of the most avoidable mistakes builders make is assuming certain items are included in a custom cabinet order without confirming them in writing. What seems “standard” to one party may not be included at all by another, leading to unexpected costs or last-minute changes.

Common points of confusion include whether cabinet hardware, side panels, fillers, crown molding, toe kicks, or soft-close mechanisms are included in the quote. In some cases, even drawer boxes, shelving, or interior accessories may be priced separately. These assumptions often aren’t discovered until installation when it’s too late to adjust without delaying the project.

To avoid this mistake, always review an itemized quotation and confirm inclusions during the shop drawing and contract approval stage. Every component, no matter how small, should be clearly listed. Eliminating assumptions upfront helps prevent budget overruns, installation delays, and uncomfortable conversations with clients later on.

How to Avoid These Mistakes

Avoiding costly cabinet ordering mistakes comes down to preparation, communication, and process. Builders who treat custom cabinetry as a coordinated system, rather than a standalone item—are far more likely to stay on schedule and within budget.

Start by finalizing site measurements and appliance selections before approving shop drawings. Review layouts with both functionality and end-user needs in mind, not just visual appeal. Allow realistic lead times for production and logistics, and build buffer time into your construction schedule. Most importantly, never assume what’s included—request detailed, itemized quotes and confirm every component in writing.

Working with an experienced cabinet supplier who understands builder workflows can also make a significant difference. Clear documentation, early coordination, and thorough review upfront will save far more time and cost than trying to fix problems after cabinets are already in production.

Summary

Ordering custom cabinets doesn’t have to be complicated, but it does require attention to detail. The most common mistakes builders make stem from incomplete planning, unclear communication, and unrealistic timelines. From measurements and appliance coordination to functionality, lead times, and scope clarity, each step plays a critical role in a successful cabinet installation.

By slowing down early, confirming specifications, and working closely with a knowledgeable cabinet partner, builders can avoid costly reorders, project delays, and client frustration. A well-planned cabinet order not only protects your schedule and budget, it also delivers a better finished product and a smoother experience for everyone involved.