In construction and interior fit-outs, selecting the right type of board is critical. From door cores to cabinets and office partitions, the materials you choose affect not only installation speed and strength, but also long-term durability and project cost.Many builders are torn between tubular chipboard and solid particle chipboard. At a glance, both are chipboard products, but their internal structure, weight, price, and performance vary greatly. This article explains their differences, ideal applications, and whether they’re worth the investment in 2026.

Tubular chipboard is a lightweight, hollow-core variant of particle board, offering up to 60% weight reduction. It’s engineered for ease of handling and fast installation in non-structural applications like interior doors, partition panels, and decorative panels. While cost-effective, it lacks edge strength and is unsuitable for heavy loads. In contrast, solid particle board is denser, stronger, and ideal for cabinetry, shelving, and countertops—where screw-holding power, dimensional stability, and long-term durability are essential for structural integrity.

Let’s explore their individual properties, differences, and where each board fits into a smart builder’s material plan.

Characteristics of Tubular Chipboard

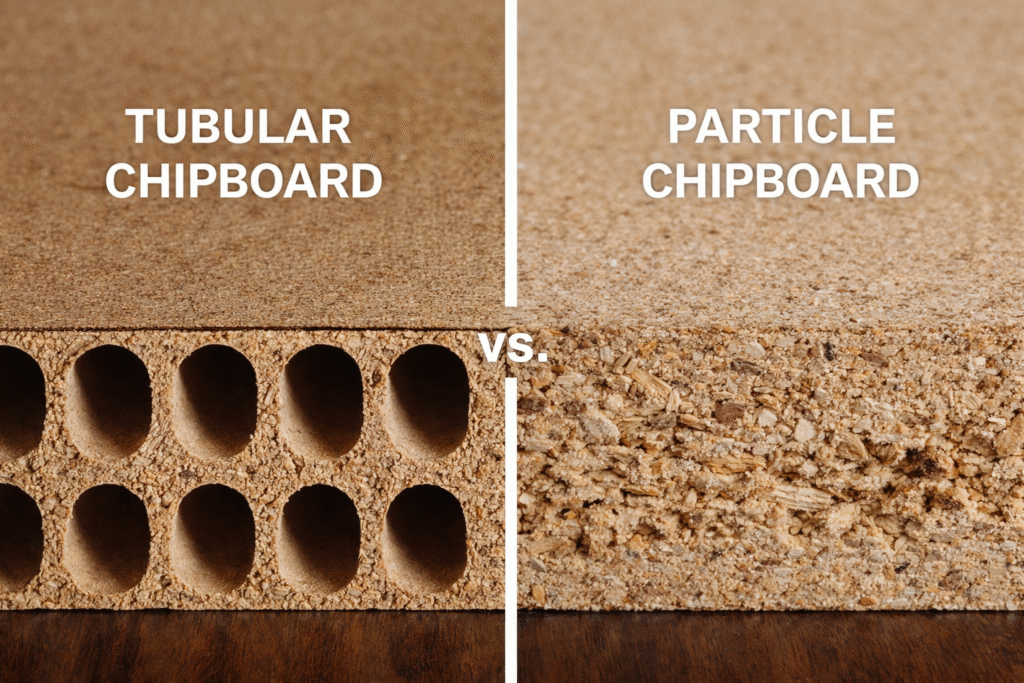

Tubular chipboard — also called hollow-core particleboard — is made by embedding a network of tubular or honeycomb cavities inside standard chipboard. This reduces weight without sacrificing too much on dimensional stability.

Key Characteristics:

- 60% lighter than standard particle board (source: Home Pillars, Madar)

- Maintains reasonable compressive strength

- Good dimensional stability, with low swelling in humid environments

- Moderate sound insulation due to hollow design

- Inexpensive, ideal for volume projects

- Low flexural strength — not suitable for horizontal spans

Common Applications:

- Interior door cores (residential and commercial)

- Partition walls and non-load-bearing room dividers

- Back panels of wardrobes or cabinets

- Office furniture panels where appearance > structure

Advantages for Builders:

- Easy to transport and lift, reducing labor fatigue

- Fast installation speeds up project timelines

- Reduced strain on hinges and fixings in door systems

Caution: Tubular chipboard has low bending strength and poor screw-holding on edges. It should never be used for shelves, countertops, or structural frames.

Characteristics of Particle Chipboard

Standard particle chipboard is a dense, solid panel composed of wood chips and resin compressed into a durable board. It’s widely used in the furniture and interior industries because of its cost-efficiency, smooth surface, and mechanical performance.

Key Characteristics:

- High density, providing good load-bearing capability

- Excellent screw-holding in both face and edge

- Even texture, easy to laminate, veneer, or paint

- Economical alternative to plywood or MDF

- Moderate moisture resistance when sealed or coated

Common Applications:

- Cabinetry and kitchen carcasses

- Closet systems and shelving

- Office desks and worktops

- Flush doors (as core or skin material)

- Underlayment panels for flooring or countertops

Advantages for Builders:

- Reliable under load — supports heavy contents and hardware

- Compatible with standard carpentry tools

- Suitable for melamine or HPL coatings

- Long-term performance (15–25 years lifespan)

Note: Particle board can swell or deteriorate in humid or wet environments unless properly sealed. Avoid using it in unprotected bathrooms or near sinks.

Tubular Chipboard vs Particle Chipboard: Side-by-Side Comparison

| Feature | Tubular Chipboard | Solid Particle Chipboard |

|---|---|---|

| Core Structure | Hollow core (tubular grid) | Solid pressed wood particles |

| Weight | Very light (up to 60% lighter) | Heavy |

| Strength (Flexural) | Low | High |

| Compressive Strength | Moderate | High |

| Screw Holding | Poor (especially on edges) | Excellent (edge and face) |

| Sound Insulation | Moderate | Slightly better due to mass |

| Moisture Resistance | Moderate if edges are sealed | Poor if untreated, better if sealed or laminated |

| Surface Finish Options | Limited | Laminate, melamine, paint, or veneer ready |

| Best Use Cases | Doors, partitions, light-duty panels | Cabinets, shelving, furniture carcasses |

| Cost per Sheet | Lower | Higher |

| Typical Lifespan | 10–15 years | 15–25 years |

Pro Tip for Builders:

Use tubular chipboard to cut project costs and reduce labor time on interior non-load applications. Stick with particle board for anything that needs to be screwed, mounted, or carries weight.

When Should Builders Use Tubular Chipboard?

Tubular chipboard offers a distinct set of advantages on certain job sites. Here’s when it’s the right call:

Use Tubular Chipboard for:

- Interior doors: Its low weight reduces stress on hinges and makes installation faster.

- Room dividers: Great for prefab wall panels where no structural load is involved.

- Light-duty furniture panels: Especially when the design emphasizes cost over strength.

- Large-volume projects: Such as hotels, offices, or schools where hundreds of doors or partitions are needed.

Avoid Tubular Chipboard When:

- Screws need to hold heavy hardware or wall anchors

- The panel is spanning horizontally without center support

- The environment involves moisture or fluctuating humidity

Builders should always assess both function and wear conditions before selecting tubular core materials.

Is Tubular or Particle Chipboard Worth the Higher Cost in 2026?

With rising raw material and labor costs in 2026, choosing the right board can greatly impact both short-term budgets and long-term performance.

Cost Comparison:

- Tubular chipboard is cheaper to purchase, transport, and install.

- Particle chipboard is more expensive per sheet but provides better lifetime durability.

ROI by Use Case:

| Use Case | Recommended Board | Why |

|---|---|---|

| Interior doors (residential) | Tubular chipboard | Lightweight, affordable, fast to install |

| Office desks / work surfaces | Particle chipboard | High compressive strength, supports mounted equipment |

| Cabinet carcasses / kitchens | Particle chipboard | Superior screw-holding and long-term support |

| Partition panels (non-struct.) | Tubular chipboard | Low-cost, easy to move, no load-bearing required |

Bottom Line:

Builders should use tubular chipboard strategically, where cost and ease matter more than strength. Invest in solid particle board for structural pieces and any furniture expected to last under pressure.

Professional Advice for Builders

Making the right material choice goes beyond just specs — it impacts everything from labor cost to customer satisfaction. Here’s what to keep in mind:

Understand the Load Requirements

If the component supports weight, fasteners, or heavy fixtures (like cabinets and shelves), always go with particle chipboard. Tubular is for light-duty only.

Balance Material Cost with Installation Cost

Tubular board can reduce overall costs on:

- Labor (lighter weight = faster fitting)

- Transport (more units per truck)

- Reduced fatigue or injury risk for installers

It’s ideal for high-volume, fast-turnaround projects like commercial builds.

Moisture is a Dealbreaker

Both boards dislike water, but tubular is especially vulnerable if moisture enters the hollow core. Use MDF or plywood for wet zones — or seal all edges carefully on chipboard.

Summary

Tubular and particle chipboard both have their place in modern construction. Tubular chipboard saves time, weight, and cost — but is best used where no structural strength is needed. Solid particle chipboard, while heavier and pricier, delivers better long-term value, strength, and versatility. In 2026, builders who understand the strengths and limits of each material will make smarter, more profitable choices — without sacrificing quality. Share this article with your crew or clients — and let us know your go-to material in your recent builds!