Introduction – What Exactly Is Shiplap?

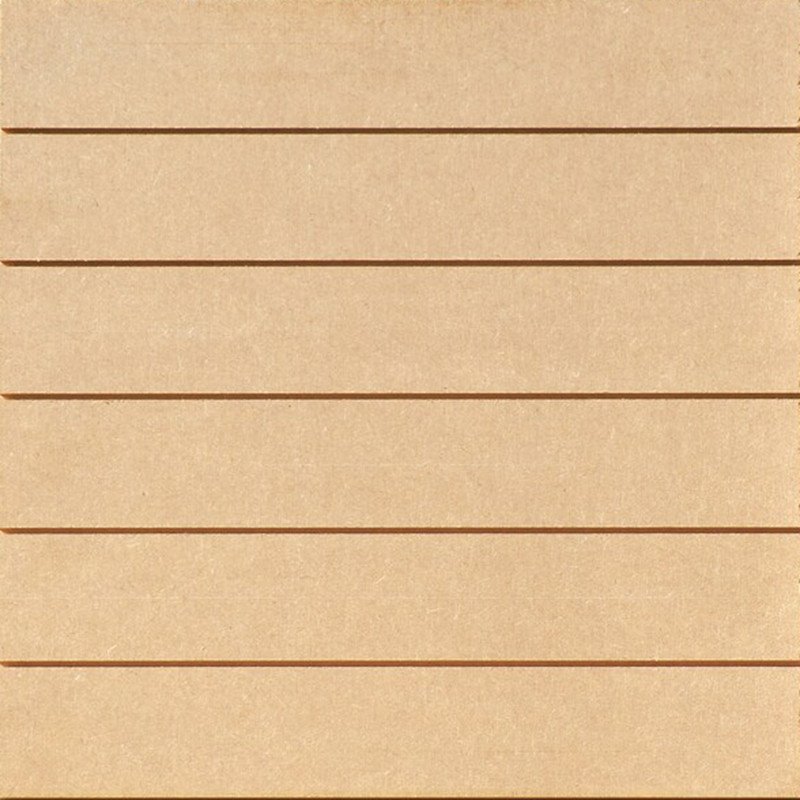

Imagine walking into a newly finished home where the walls feature clean horizontal lines, creating a subtle rhythm and texture that immediately draws your eyes. That elegant, layered look comes from shiplap boards—a design element that has quietly become one of the most recognizable wall finishes in modern construction.

Shiplap refers to a type of wooden board that overlaps through a rabbet joint—a groove cut into the edge of the board—allowing one panel to fit neatly over the next. When installed, this overlapping system produces a tight seal and a distinctive shadow line that gives walls depth and dimension. Originally, shiplap was used on the exterior siding of barns and cottages to create a wind- and water-resistant barrier. Over time, its functional benefits and simple beauty led designers to bring it indoors, where it now appears on interior walls, ceilings, and feature panels.

In both residential and commercial projects, shiplap offers a timeless balance of practicality and visual appeal. Builders appreciate its easy installation and clean alignment, while homeowners love the warmth and texture it adds to any room. But while traditional wood shiplap has been used for decades, newer materials—especially MDF (Medium Density Fiberboard) shiplap boards—are changing the game with better stability, affordability, and finish consistency.

How Traditional Shiplap Boards Work

Traditional shiplap boards are made from solid wood, commonly pine, cedar, or fir. Each board is milled with a rabbet joint—a small L-shaped notch on opposite sides of the board. When installed, the upper edge of one board overlaps the lower edge of the next, forming a snug, layered connection. This overlapping system is the key to shiplap’s name and function: it allows the boards to “ship” or slide into each other, creating a tight seal that helps prevent drafts, moisture, and warping.

Originally, shiplap was used as exterior siding in barns, cottages, and coastal houses. The design protected structures from harsh weather by letting rainwater run off easily while allowing the wood to expand and contract naturally. Builders found that shiplap offered a strong balance between weather resistance and structural simplicity—no complicated joints, just precise cuts and clean alignment.

In modern construction, shiplap has evolved from a purely functional siding to a decorative interior material. Designers and builders use it for accent walls, ceilings, and hallway paneling, especially in farmhouse-style or coastal interiors. Its horizontal lines make spaces appear wider and add a sense of calm order to a room.

However, traditional shiplap does have its drawbacks. Because it’s made from natural wood, it’s sensitive to humidity and temperature changes. Without proper sealing, the boards can warp, crack, or develop gaps over time. In addition, solid wood boards can be costly and often require finishing, sanding, and painting on site, increasing labor and material costs.

These challenges have driven many builders and distributors to explore alternatives that retain the same visual appeal but eliminate maintenance issues—leading to the growing popularity of MDF shiplap boards.

Why MDF Shiplap Boards Are Becoming Popular

In recent years, MDF shiplap boards have become a preferred choice among builders, wholesalers, and interior contractors who seek both aesthetic consistency and installation efficiency. MDF, short for Medium Density Fiberboard, is made by pressing fine wood fibers with resin under high temperature and pressure. The result is a dense, uniform panel that offers superior smoothness and stability compared to natural wood.

One of the biggest advantages of MDF shiplap is its dimensional stability. Unlike solid wood, MDF does not expand or contract noticeably with humidity or temperature changes. This means the boards maintain a tight, clean joint line year-round, without the risk of warping, cupping, or cracking—an essential factor for builders who want to reduce post-installation callbacks.

Another advantage is surface quality. MDF shiplap boards have an ultra-smooth surface that’s ideal for painting or UV priming. Manufacturers often pre-prime or even pre-finish the boards, allowing installers to save significant on-site labor time. This is especially attractive for commercial or multi-unit residential projects, where speed and consistency are key.

From a cost perspective, MDF is typically more affordable than solid wood, both in raw material and finishing costs. Its uniform density also makes it easier to machine and cut, enabling precise tongue-and-groove or overlapping edges that fit perfectly during installation. Builders appreciate that MDF shiplap can be installed faster, with minimal adjustment or waste.

In terms of application, MDF shiplap is ideal for interior wall paneling, ceilings, and decorative feature walls. It’s widely used in living rooms, offices, hotels, and retail spaces, where designers want a refined, painted look without the rustic irregularities of wood grain. Some manufacturers even offer moisture-resistant MDF suitable for bathroom dry zones or laundry rooms, expanding the range of use.

Environmentally, MDF shiplap also aligns with sustainability goals. It makes use of recycled wood fibers and reduces the demand for solid lumber. For distributors and wholesalers, MDF offers consistent sizing, easy packaging, and reliable supply—all critical for maintaining large-volume inventory and meeting project timelines.

In short, MDF shiplap boards deliver the same aesthetic effect as traditional shiplap while offering better stability, smoother finishes, and lower total project cost. These practical benefits explain why more professionals are switching from solid wood to MDF in modern construction.

MDF Shiplap vs. Wood Shiplap – Key Differences

For builders and wholesalers, choosing between wood and MDF shiplap often comes down to balancing appearance, performance, and budget. Both materials share the same overlapping design concept, but their properties—and their real-world performance—differ significantly. The comparison below highlights the most important distinctions.

| Feature | Wood Shiplap | MDF Shiplap |

|---|---|---|

| Material Composition | Made from solid timber such as pine, cedar, or fir. | Made from compressed wood fibers bonded with resin. |

| Appearance | Natural wood grain with unique texture and knots. Ideal for rustic or farmhouse styles. | Ultra-smooth surface, uniform texture, and perfect for painted or modern interiors. |

| Dimensional Stability | Can expand, shrink, or warp with humidity changes. | Highly stable; maintains shape and tight joints even in varying conditions. |

| Surface Finish | Requires sanding and multiple coats of primer or paint on site. | Often pre-primed or pre-finished for immediate installation. |

| Installation | May require adjustment due to inconsistent thickness or warping. | Consistent sizing ensures quick and precise fitting. |

| Maintenance | Needs periodic sealing or repainting to protect against moisture. | Low maintenance; easy to repaint or touch up when needed. |

| Durability | Strong and natural but can be affected by insects, moisture, or cracking. | Resistant to warping and cracking; moisture-resistant options available for dry-zone interiors. |

| Cost Efficiency | Higher material and labor cost due to preparation and finishing work. | More affordable and faster to install, saving total project costs. |

| Best Applications | Rustic cabins, exterior siding, or farmhouse-style interiors. | Modern interiors, commercial projects, and painted feature walls. |

In practical terms, wood shiplap remains unmatched when a natural, textured, and authentic aesthetic is desired. Its warmth and character suit traditional or rustic architecture perfectly. However, for modern construction, where precision, consistency, and smooth finishes matter, MDF shiplap provides a more versatile and cost-effective solution.

Many professional builders now specify MDF for indoor applications, while reserving natural wood for outdoor or specialty design work. Wholesalers and distributors also favor MDF because it offers consistent dimensions, uniform surface quality, and simplified logistics—reducing returns and installation issues.

Conclusion

In today’s construction market, MDF shiplap boards offer builders and distributors a smarter, more practical alternative to traditional wood. They deliver the same classic shiplap look with greater stability, smoother finishes, and lower costs. Easy to paint, install, and maintain, MDF shiplap combines timeless design with modern efficiency—making it the ideal solution for interior projects that demand both quality and value.