Imagine overseeing a commercial project where you need to source interior doors on a tight budget and timeline. The client demands affordability, durability, and soundproofing, but with so many options, which core material will offer the best balance of performance and cost? The answer lies in understanding the core materials of interior doors.

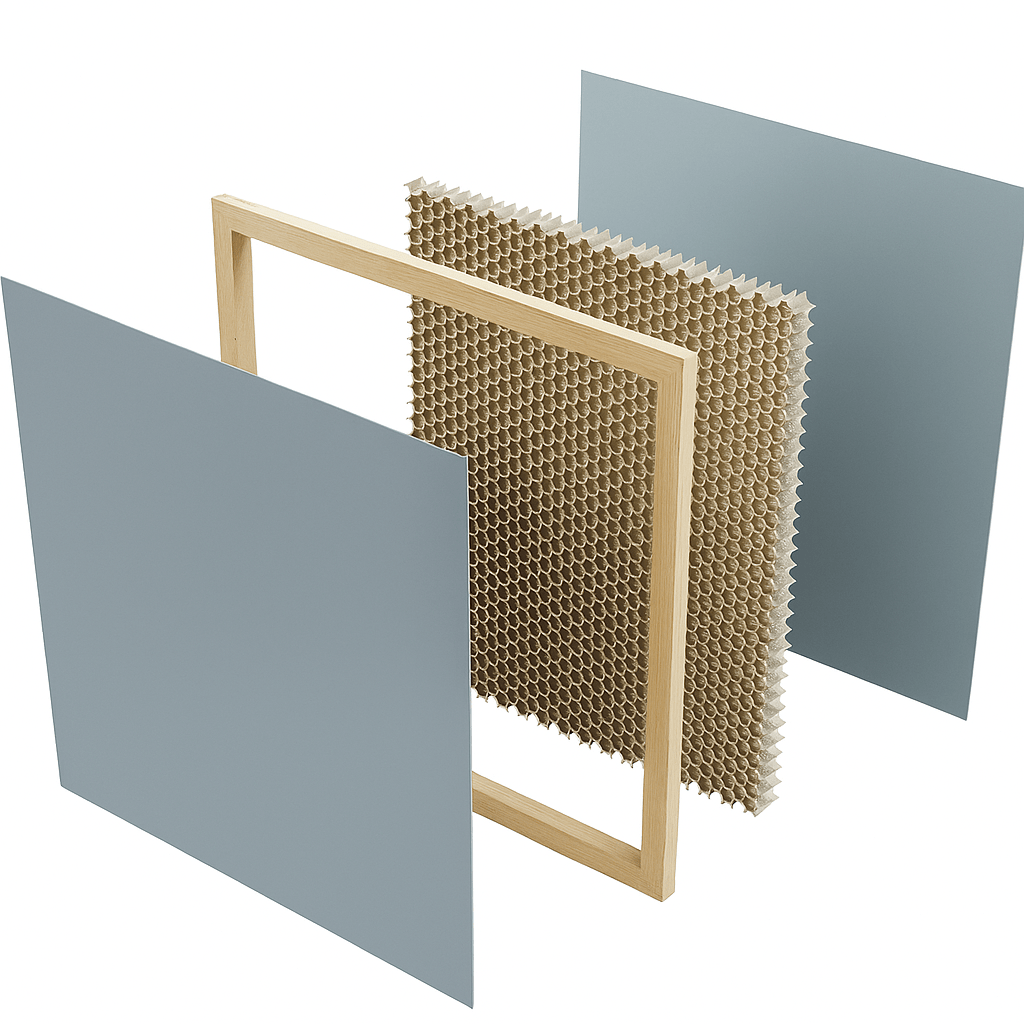

Hollow Core – Honeycomb Paper: Lightweight & Cost-Effective

Honeycomb paper is the most widely used filling in hollow core doors. It’s made by expanding kraft paper into a hexagonal structure, similar to a beehive. This structure creates a series of air pockets that contribute to the material’s lightweight and strong yet flexible properties.

Honeycomb paper core is often used in interior doors due to its high strength-to-weight ratio, making it both durable and easy to handle. The material is also cost-effective, making it an ideal choice for large-scale projects where budget is a major consideration.

Why Choose Honeycomb?

- Cost-effective: Ideal for budget-sensitive projects where performance is still a priority.

- Lightweight: Its air-filled structure makes the door easier to transport and install while maintaining sufficient strength.

- Environmentally friendly: Made from recycled paper, this option is an eco-friendly alternative compared to other materials.

- Strong and resilient: The hexagonal structure of honeycomb core provides resistance to compression, making it more durable than other lightweight materials.

- Good soundproofing: Offers decent sound insulation properties, suitable for areas with moderate noise levels.

Best For:

- Residential housing, multifamily units, office buildings

- Projects requiring affordable solutions at scale without compromising basic durability or soundproofing

Honeycomb core doors are perfect for applications where cost-efficiency is key, but a certain level of strength and insulation is still required. They are commonly found in apartment buildings, hotel rooms, and interior doors where lightweight and ease of installation are important.

Note: While honeycomb is economical, it’s not ideal for high-traffic or moisture-prone environments.!

Solid Core – Solid Wood: Natural Strength and Elegance

Solid wood core doors are constructed using solid wood panels as the core material, providing natural beauty, strength, and premium quality. These doors offer a classic, high-end aesthetic and are commonly used in both luxury homes and high-end commercial applications. The solid wood core is designed to be structurally strong, providing excellent durability and soundproofing properties.

Solid wood doors can also be more impact-resistant than other core options, making them ideal for areas where strength is a priority. The doors can be finished with a variety of stains, paints, or veneers to match different architectural styles.

Why Choose Solid Wood?

- Natural strength: Solid wood provides superior durability and can withstand heavy usage while maintaining its integrity.

- Premium feel: The natural appearance and texture of solid wood doors add a high-end look to any interior.

- Better soundproofing: Solid wood provides excellent sound insulation, making it ideal for rooms where noise reduction is important.

- Long-lasting: Solid wood doors are known for their longevity, often lasting for decades if properly maintained.

Best For:

- Luxury homes, high-end commercial spaces

- Offices, conference rooms, or high-traffic areas where strength and aesthetic appeal are important

- Private homes and residential spaces where premium finishes and natural materials are preferred

Solid wood core doors are perfect for high-end residential projects and premium commercial spaces, offering both natural beauty and robust performance. If you’re looking for elegance and long-term value, solid wood core doors are a top choice.

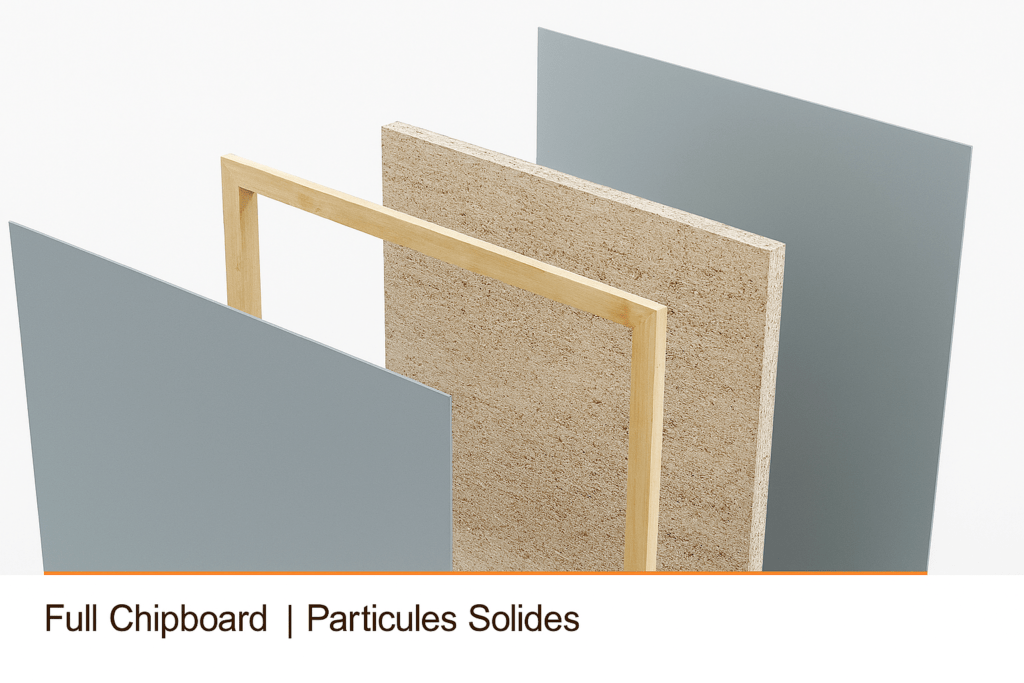

Solid Core – Full Chipboard: Stable and Strong

Full chipboard (also known as solid particle board) is a compressed wood fiber board used as a core material for higher-end interior doors. The core is made by pressing wood fibers and resin together under heat and pressure to create a dense, solid material. It provides excellent durability, sound insulation, and stability. Full chipboard is known for its reliable structural performance and is commonly used in doors that need to withstand frequent use while maintaining a high-quality finish.

Full chipboard is a popular choice for mid-to-high-range commercial projects and residential spaces where durability and aesthetics are equally important. The material offers a smooth surface that can be easily painted or veneered, making it a versatile option for achieving a premium look.

Why Choose Full Chipboard?

- Great sound insulation: The dense structure helps reduce noise transmission, making it an ideal choice for office buildings, conference rooms, or bedrooms.

- Smooth surface: The uniform, smooth finish is perfect for painting or applying veneers to match interior design schemes.

- Heavier feel: Full chipboard doors are solid and substantial, giving a premium feel and better performance in high-traffic areas.

- Durable and stable: Full chipboard doors are resistant to warping, making them suitable for environments with humidity variations or high-use areas.

- Good value for quality: Provides the strength of a solid core door at a more affordable price compared to other solid core materials like MDF or wood.

Best For:

- Commercial buildings, offices, hospitality spaces

- High-end residential homes where both performance and aesthetic appeal matter

- Schools and libraries that require soundproofing and durability

Full chipboard doors are perfect for commercial applications and luxury homes where you need reliable performance, stability, and sound insulation, while still achieving an elegant look.

Tip: For doors over 90 inches, solid chipboard adds dimensional stability and prevents warping.!

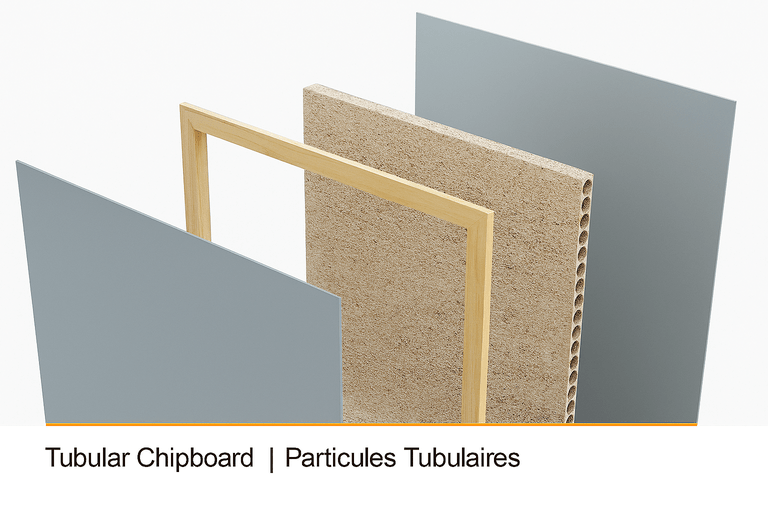

Tubular Core – Tubular Chipboard: Strength Meets Weight Balance

Tubular chipboard, also known as tubular core, features a unique grid-like structure of hollow tubes formed within the chipboard. This internal structure offers a good balance between weight, strength, and soundproofing. Tubular chipboard doors are particularly suitable for applications that require both resilience and lightweight performance. The core provides the stability of solid core materials while maintaining a lighter weight, making it easier to handle and install compared to full chipboard or solid wood doors.

This material strikes an optimal balance between cost and performance, making it an excellent choice for commercial projects or buildings with specific acoustic or durability needs. It is designed to resist deformation, and its unique structure also offers good thermal insulation, making it a versatile and reliable choice.

Why Choose Tubular Core?

- Stronger than honeycomb, but lighter than solid chipboard: Provides the strength and durability of solid cores, but at a more manageable weight.

- Improved screw holding strength: The grid structure gives better screw-holding capability, which makes it ideal for doors that require hardware installation, such as locks, hinges, and handles.

- Better resistance to deformation: The tubular design helps the door maintain its shape and structural integrity over time, even in environments with fluctuating temperatures and humidity.

- Good sound insulation: While not as soundproof as full chipboard, tubular chipboard offers better acoustic performance than honeycomb core doors, making it suitable for areas where moderate soundproofing is important.

Best For:

- Schools, hotels, public facilities

- Mid-to-high durability projects that require a moderate budget

- Libraries, conference rooms, or office spaces where sound insulation and durability are needed but cost is a consideration

Tubular chipboard is an ideal choice for commercial buildings that require strength, lightweight performance, and good acoustics while staying within budget. It’s perfect for high-traffic areas or any project where durability and resistance to deformation over time are important factors.

Especially suitable for pre-assembled doors shipped long distances.!

Fire-Rated Core – Magnesium Oxide Board: Safety First

Magnesium oxide (MgO) boards are commonly used in fire-rated doors and are highly valued for their fire resistance. MgO is a non-combustible and moisture-resistant material, providing excellent thermal protection in high-risk areas. This material is often preferred in fire-rated doors due to its ability to withstand extreme temperatures and resist the spread of flames for extended periods.

MgO boards are dimensionally stable under heat, meaning they maintain their structural integrity even in extreme conditions. This makes them one of the most reliable options for high-performance fire-rated doors. The fire-resistant properties of MgO doors are certified by UL20 and UL90, ensuring that they meet the strictest fire safety standards.

In addition to its fire resistance, magnesium oxide board is also environmentally friendly and provides better mold and mildew resistance compared to other fire-rated materials.

Why Choose MgO Board?

- Certified fire resistance: Meets UL20, UL90, and other fire safety certifications, making it suitable for high-risk environments.

- Doesn’t emit toxic fumes: Unlike other fire-rated materials, MgO boards do not release toxic gases when exposed to high heat, ensuring a safer evacuation during a fire.

- Mold- and moisture-resistant: MgO boards provide superior resistance to moisture, making them ideal for areas prone to humidity, such as basements or kitchens.

- Durable and long-lasting: MgO boards are resistant to warping, cracking, and degradation over time, making them a reliable choice for fire-rated doors.

- Eco-friendly: Made from natural materials, magnesium oxide boards are a sustainable choice that minimizes environmental impact.

Best For:

- Fire-rated corridors, hotel rooms, exit doors

- Areas where fire code compliance is mandatory, such as high-rise buildings, commercial properties, and industrial settings

- Utility rooms, basements, and areas with high moisture exposure, where both fire resistance and moisture protection are essential

Magnesium oxide board is the top choice for fire-rated doors where maximum fire protection, moisture resistance, and structural integrity are critical. This material ensures compliance with fire codes while providing reliable safety and long-term performance.

We offer fire doors tested and certified under UL20 and UL90 standards.

Quick Comparison Table

| Core Type | Strength | Soundproof | Fire Resistance | Cost | Best Use |

|---|---|---|---|---|---|

| Honeycomb | ⭐⭐ | ⭐⭐ | ❌ | $ | Budget housing, bulk orders |

| Full Chipboard | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ❌ | $$$ | Office, luxury homes |

| Tubular Chipboard | ⭐⭐⭐⭐ | ⭐⭐⭐ | ❌ | $$ | Hotels, mid-high projects |

| MgO Board | ⭐⭐⭐⭐ | ⭐⭐⭐ | ✅✅✅ | $$$$ | Fire-rated doors in any setting |

Solid Core vs Hollow Core Doors

Solid Core Doors:

- Denser, stronger, better soundproofing.

- Ideal for high-traffic, commercial, or luxury spaces.

- Higher cost and heavier weight.

Hollow Core Doors:

- Lightweight, cost-effective.

- Good for standard residential or office applications.

- Lower durability and soundproofing than solid cores.

Conclusion: Choose based on your budget, durability needs, and soundproofing requirements, rather than assuming one type is universally better.

Is a Solid Core Door Always Better Than a Hollow One?

When selecting doors for a project, one of the most common questions is whether a solid core door is always better than a hollow core door. The answer depends on your specific needs and the environment where the door will be installed. Both solid core and hollow core doors have their advantages, and understanding these will help you make the best choice for your project.

Solid Core Doors: Strength and Durability

Solid core doors are made from materials like full chipboard or solid wood, making them denser and heavier than hollow core doors. This provides superior strength, sound insulation, and better impact resistance. They are often the preferred choice for areas that experience high traffic or where noise reduction is essential.

However, solid core doors can be more expensive and heavier, which may make them less ideal for certain applications where weight and cost are concerns. They also tend to cost more due to the materials used in their construction.

Hollow Core Doors: Lightweight and Cost-Effective

Hollow core doors, particularly those with a honeycomb core, are lightweight and generally more affordable. They offer good performance for everyday use and are often used in residential or budget-conscious commercial applications. The hollow structure provides strength and stability without the heavy weight of solid core doors.

The downside to hollow core doors is that they offer less sound insulation and may not be as durable or impact-resistant as solid core doors. However, they are an excellent choice where budget and ease of installation are key considerations.

Conclusion: Which Is Best for You?

- Solid Core Doors are ideal when you need maximum durability, soundproofing, and a premium feel. They’re the right choice for areas with high traffic, commercial spaces, or luxury residential settings.

- Hollow Core Doors are the best option when you’re looking for lightweight, cost-effective doors for standard applications like residential homes, interior rooms, or offices.

In short, it’s not about which is “better” overall, but which one fits your specific needs. Both types of doors have their place in construction projects—choose the one that best meets your performance requirements, aesthetic goals, and budget.

FAQ

Q1: What is the difference between solid core and hollow core doors?

A: Solid core doors are heavier, stronger, and provide better sound insulation, while hollow core doors are lightweight and more cost-effective.

Q2: Which interior door core material is best for commercial projects?

A: Full chipboard and tubular chipboard are ideal for commercial projects, balancing strength, durability, and soundproofing.

Q3: Are honeycomb core doors soundproof?

A: Honeycomb core doors offer moderate sound insulation, suitable for apartments and offices with average noise levels.

Q4: Which doors are fire-rated and comply with UL standards?

A: Magnesium Oxide (MgO) board doors are UL20/UL90 certified and provide superior fire resistance.

Q5: What is the most cost-effective interior door core material?

A: Honeycomb core doors are the most budget-friendly while maintaining basic strength and soundproofing.

Conclusion

Selecting the right interior door core material is crucial for ensuring that your doors meet the specific needs of your project—whether it’s cost-efficiency, sound insulation, fire safety, or durability. From budget-friendly honeycomb cores to strong and fire-resistant magnesium oxide boards, we offer a variety of options to suit different requirements.