Imagine you’re overseeing a commercial project, and the client asks you to source interior doors. The project timeline is tight, the budget is strict, and fire safety is a priority. Which door core material will offer the best balance of fire resistance, cost, and performance?

In modern construction proiects, ire safty is a crucial aspec that cannot be overlooked. As a key component in efectively preventing the spread of fire. the selection of fire-rated wood doors directly impacts both occupant safety and building code compliance. so, what are the common fire rating standards, and how should you choose the right fire-rated wood door? Fire-rated wood doors play a vital role in preventing fire spread in modern buildings, Common standards include UL 10C/NEPA 252 (Noth America, EN 1634-1/EN 13501-2 (Europe), Bs 476(UK, GB 12955 (china), and As 1530.4 (Australia). These standards cassifv doors by fire resistance duration-20. 45 60.90 minutes-suitable for different risk areas. When choosing a fire-rated door,first confirm the required fire rating per local codes, Then select the right core material such as mineral cores, Mgo boards, or solid wood, balancing performance and cost. Also, ensure frames, seals, and hardware are certifed. Finaly, opt for manufacturers with multiple certifications and reliable production, and consider appearance and customization options.

Common Standards for Fire Rated Wood Doors

- UL 10C / NFPA 252 (North America)

Who uses it? United States and Canada

Test type: Positive pressure test with flaming exposure

Ratings: 20 / 45 / 60 / 90 / 120 minutes

Common certifications: UL mark, WHI (Warnock Hersey), Intertek

Remarks: Widely accepted in commercial projects; strict requirements on hardware and gasketing

- EN 1634-1 & EN 13501-2 (Europe & Middle East)

Who uses it? EU countries, Middle East, some Asian regions

Test type: Integrity (E), Insulation (I), Radiation control (W)

Ratings: EI30 / EI60 / EI90 / EI120

Common certifications: CE mark

Remarks: European standards test heat insulation, not just flame resistance; higher demands on door set as a whole

- BS 476 Part 22 (United Kingdom & Commonwealth)

Who uses it? UK, Hong Kong, Singapore, and former Commonwealth countries

Test type: Load-bearing and non-load-bearing door assemblies under fire

Ratings: FD30 / FD60 / FD90 / FD120

Remarks: Still in use for legacy projects, though being gradually replaced by EN standards

- GB 12955-2008 (China)

Who uses it? Mainland China projects

Test type: Fire resistance integrity only

Ratings:

Grade A: 1.5 hours

Grade B: 1.0 hour

Grade C: 0.5 hour

Remarks: Often paired with GB/T 7633 testing method; CCCF certification required for public buildings

- AS 1530.4 (Australia & New Zealand)

Who uses it? Australia, New Zealand

Test type: Similar to EN 1634-1, includes insulation performance

Ratings: 30 / 60 / 90 / 120 minutes

Remarks: Used in combination with the NCC (National Construction Code)

Understanding Fire Door Ratings: What Do 20, 45, 60, and 90 Minutes Really Mean?

Fire-rated doors are classified based on how long they can resist fire and high temperatures without failing. The most common classifications in North America include:

- 20-Minute Rating: Suitable for light commercial or residential unit entries.

- 45-Minute Rating: Often used in corridors, stairwells, and lobbies.

- 60-Minute Rating (1 Hour): Typical in more fire-sensitive zones like utility rooms.

- 90-Minute Rating: Required in more critical areas such as stair towers or elevator lobbies.

These durations are not guesses—they are verified through rigorous third-party testing according to standards such as:

- UL 10C: UL10C is a U.S. fire door testing standard that simulates real fire conditions under positive pressure, making it more realistic than older standards like UL10B. The door assembly is exposed to high temperatures for 20 to 120 minutes, and must resist flame penetration, maintain structural integrity, and keep hardware functional. Flame leakage is tested using a cotton pad. While smoke testing isn’t required by UL10C, it’s often paired with UL 1784 for smoke control performance. Overall, UL10C is stricter and more suitable for modern safety requirements.

- NFPA 252: Standard Methods of Fire Tests of Door Assemblies. NFPA 252 is a U.S. standard that tests fire-rated doors and windows by exposing them to fire based on ASTM E119. It checks if they maintain integrity, prevent flame passage, and limit heat transfer for 20 to 90 minutes. Hardware function is also tested afterward. This standard is widely used in North America for fire door certification and building code compliance.

What Makes a Fire-Rated Wood Door Fire-Rated? It’s More Than Just the Core

While the exterior of a fire-rated wood door might resemble a regular door, the fire resistance lies in its internal construction and certified components. Key factors include:

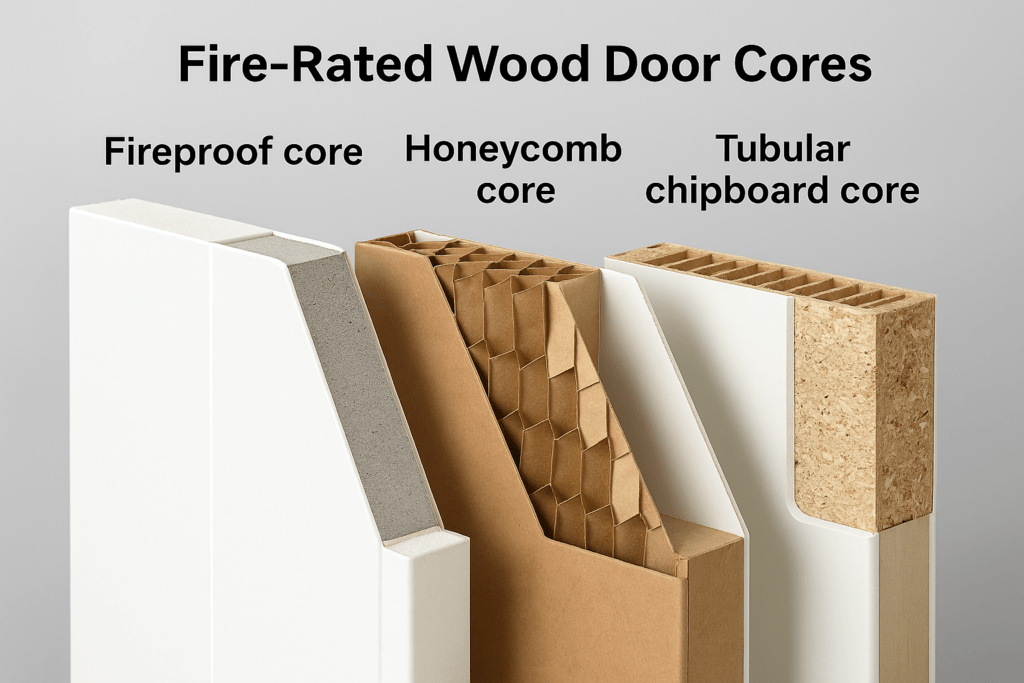

- Core Material: We use mineral cores, solid particle cores, or fire-resistant honeycomb cores, depending on rating and customer preferences.

- Door Thickness: Standard fire-rated wood doors are 45mm or thicker, depending on the rating.

- Edge Sealing: Intumescent seals around the perimeter expand in heat, blocking smoke and flames.

- Frame Compatibility: Fire-rated doors must be installed in matching rated frames (wood or steel) to be code-compliant.

- Certified Hardware: Hinges, locks, closers, and vision kits must also be tested and listed as part of the fire door assembly.

At United Woods Group, we manufacture complete fire-rated door sets, including pre-installed fire-rated hardware, and offer customization for your project’s specific needs. Our products are labeled for easy inspection and peace of mind.

Certifications & Compliance: How to Ensure Your Door Meets the Code

Every fire-rated wood door must include a clearly visible label, typically placed on the hinge edge or top of the door, showing:

- The fire rating duration (e.g., 45 or 90 minutes)

- The testing agency (UL, Intertek/Warnock Hersey)

- A unique serial number and listing detail

- The manufacturer’s name and location

Without these labels, your door will not pass inspection—no matter how well-made it is.

Choosing the Right Fire-Rated Door: 5 Practical Tips for Builders and Wholesalers

For builders, contractors, or material wholesalers, selecting the right fire-rated doors is not just about code compliance—it directly impacts project delivery timelines, overall costs, and future maintenance risks.

Here are 5 practical tips to help you source fire doors efficiently and professionally:

- Confirm the Required Fire Rating: Different projects require different levels of fire resistance. Common ratings include 20, 45, 60, 90, and 120 minutes. Before purchasing, you must determine the required rating based on building usage and local fire codes. For example:Apartment entry doors typically require at least 60 minutes of fire resistanceCommercial corridor doors may require 90 minutes or higher✅ Tip: Choose products that are certified by reputable institutions such as UL, Intertek (WH), FM, or BS to ensure they meet inspection and code requirements.

- Evaluate the Door Core Material and Performance: The door core is the key component that determines fire resistance. Common core materials include:Mineral Core (Honeycomb Rock Wool): Lightweight, cost-effective, commonly used for 45-60 min ratingsHigh-Density MgO (Magnesium Oxide Board): Stable fire performance, suitable for 60-90 min doorsSolid Wood or Engineered Wood Core: Ideal for high-end projects requiring both strength and sound insulationSteel Reinforced Core: Designed for extreme fire protection needs✅ Tip: Choose the core based on a balance of fire rating, budget, sound insulation, stability, and weight.

- Don’t Overlook the Hardware System: Even if the door leaf is fire-rated, the locks, hinges, closers, and seals must also be certified for fire use. Otherwise, the entire door system may fail inspection.✅ Tip: Opt for fully certified fire door sets where the door leaf and hardware are tested together as a complete unit—this reduces risk and avoids delays.

- Assess the Manufacturer’s Certification and Capacity:For bulk orders, supply chain stability and certification matter. A qualified supplier should offer:Multiple fire-rating certifications (e.g., UL10c, BS476)Original testing reports and traceable batch numbersOEM customization for door size and surface optionsReliable monthly output and lead time control✅ Tip: Prioritize factory-direct manufacturers with export experience, complete certifications, and technical support, rather than trading companies with limited control.

- Balance Fire Safety with Aesthetics and Customization: Modern projects often require fire-rated doors that also look good. Features such as woodgrain finishes, invisible frames, glass vision panels, and smoke seals are becoming standard.✅ Tip: Discuss finish options with your factory—such as PVC film, HPL, wood veneer, or paint—and confirm whether they support fire-rated glazing or aluminum inlays to match your design goals.

Conclusion: Choosing the Right Fire-Rated Wood Door

Choosing the right fire-rated wood door isn’t just about meeting building codes—it’s about ensuring safety and protecting property. Understanding key fire rating standards, test methods, and the differences in core materials and certified hardware can help you find a solution that balances compliance, budget, and performance. Don’t overlook the importance of full door assembly certification and proper installation. This guide aims to give you a clear starting point for making informed, confident decisions in your fire door procurement.