Molded doors offer a stylish, cost-effective alternative to traditional wooden doors. But what exactly are they—and why are they so common in modern construction? If you’re building, buying, or budgeting, understanding this option can save you time and money.

Now that we’ve defined what a molded door is, let’s break down how they’re built, where they work best, and how they compare to other common door types.

What is a Molded Door?

A molded door, also called a molded panel door, is an interior door made by pressing or molding two panels together to create a specific design. Typically made from MDF (Medium-Density Fiberboard), these doors can have smooth or textured surfaces and are available in hollow or solid-core options.

Key features of molded doors:

- Affordable and lightweight

- Consistent quality and uniform design

- Ready-to-paint with a primer coat, or available pre-finished

- Suitable for bedrooms, bathrooms, closets, hallways, and interior cabinets

Molded doors combine versatility and style, making them a popular choice for modern homes and commercial interiors.

How Molded Doors are Made

Door Skin

- Constructed from MDF, shaped under high-pressure compression

- Available in 2-panel, 6-panel, arch-top, or flat panel designs

- Can be smooth or textured to mimic wood grain

- Usually comes primed for easy painting

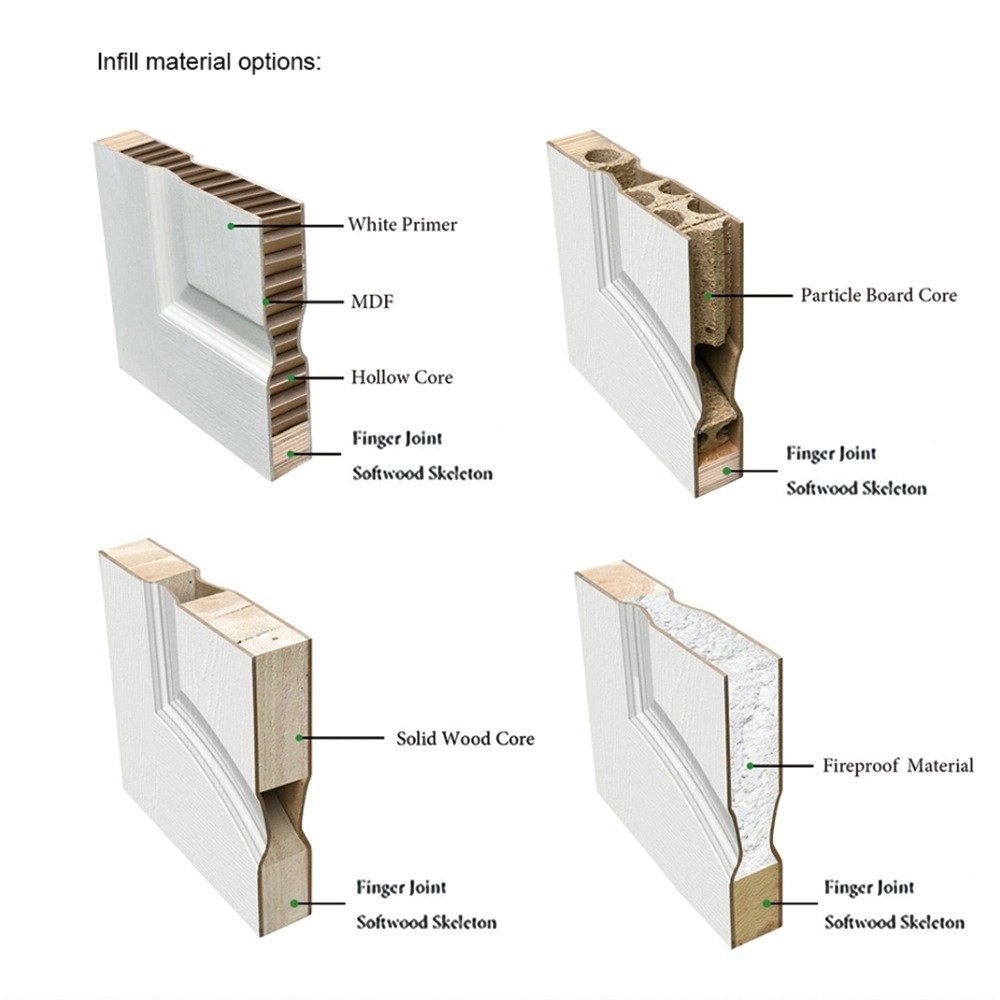

Core Material

The interior filling affects strength, durability, and soundproofing. Common types include:

| Core Type | Characteristics | Best For |

|---|---|---|

| Honeycomb Paper Core | Lightweight, low cost | Standard interior doors |

| Particleboard Core | Better sound insulation | Bedrooms, offices |

| Tubular / Solid Core | High durability, dense | Areas requiring stronger doors |

Stiles and Rails (Door Frame)

- Edges are reinforced with solid wood for structural stability

- Provides strong screw-holding for hinges and locks

Surface Coating

- Most molded doors come with a white primer coat, allowing for custom painting after delivery.

- Optional finishes include factory painting, film lamination, or veneer.

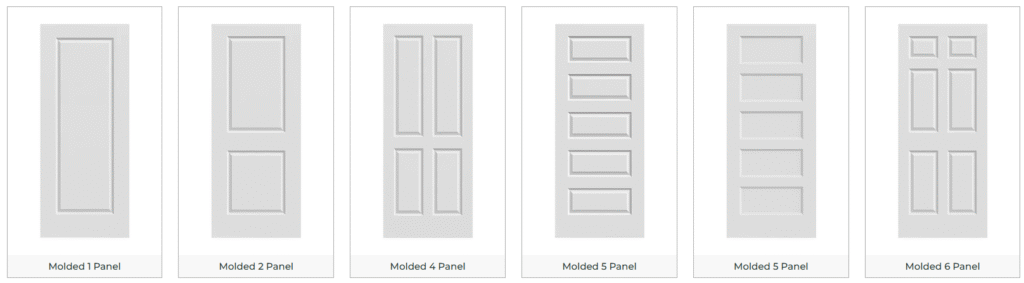

Common Molded Door Styles

Molded doors come in a wide variety of styles, which makes them appealing to homeowners and builders alike. You’ll find:

- Two-panel and six-panel doors – classic and versatile

- Arch-top or square-top panels – decorative touches

- Smooth or textured finishes – mimic real wood or offer sleek modern look

- Popular designs: Cambrian style with clean lines and subtle paneling

One popular design is the Cambrian door style, which features clean lines and subtle paneling—perfect for modern and transitional interiors.

This variety makes molded doors flexible for everything from minimalist homes to more traditional spaces.

Advantages and Disadvantages of Molded Doors

Like any product, molded doors have their pros and cons:

| Advantages | Disadvantages |

|---|---|

| Affordable compared to solid wood | Not ideal for high-moisture areas |

| Variety of surface designs | Less durable than hardwood over time |

| Lightweight and easy to install | Difficult to modify or trim extensively |

| Mass-producible and consistent | Quality varies in low-cost market |

They stack up well in terms of value, especially when comparing a molded composite door vs MDF or molded composite door vs wood. For most interior uses, they offer a smart middle ground between budget and style.

Suitable Applications for Molded Doors

Molded doors are typically designed for interior use—you’ll often see them installed in:

- Bedrooms and closets

- Hallways and linen cabinets

- Bathrooms (as long as humidity is controlled)

They’re not ideal as exterior doors unless specially treated and sealed. If you’re wondering what is a molded door used for, the answer is simple: anywhere indoors where you need an affordable, good-looking door.

Molded Doors vs Other Door Types

- Molded Door vs Solid Wood Door: Lower cost, lighter, easier to install, but less durable than solid wood.

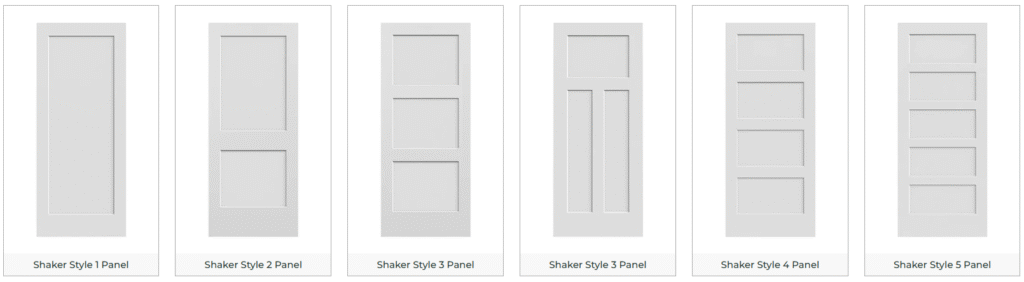

- Molded Door vs Shaker Door: Shaker doors feature simple, recessed panels and a clean, minimalist look. Molded doors can mimic the Shaker style at a lower cost, but Shaker doors made from solid wood offer greater durability and a more authentic wood appearance.

- Molded Door vs Flush Door: Molded doors have decorative paneling, while flush doors are flat and minimal, providing a sleek, modern look.

Shaker-Style Molded Doors

Molded doors are not limited to traditional panel designs—they can also be crafted in Shaker style, combining the clean, minimalist lines of Shaker doors with the cost-effectiveness of molded construction.

Features of Shaker-style molded doors:

- Simple, clean lines with a recessed center panel

- Minimalist aesthetic suitable for modern, transitional, and contemporary interiors

- Can be hollow-core or solid-core, depending on durability needs

- Available pre-primed for painting or factory-finished for convenience

- Works well for kitchens, bathrooms, closets, and interior rooms

This hybrid approach allows homeowners and builders to achieve the elegant, timeless look of Shaker doors without the higher cost of solid wood. It also makes it easy to match other molded door styles in a home for a cohesive design.

Molded Door Assembly and Delivery Options

Molded doors are available in different assembly and delivery formats, giving builders and homeowners flexibility depending on installation needs:

- Slab Doors:

- A single, flat or molded door panel without a frame or hardware.

- Ideal for projects where custom framing or hardware will be installed separately.

- Offers maximum flexibility in sizing and finishing.

- RTA (Ready-to-Assemble) Molded Doors:

- Pre-manufactured panels that can be assembled on-site.

- Convenient for contractors or DIY projects.

- Combines molded panel aesthetics with simplified shipping and handling.

- Prehung Molded Doors:

- Doors that come already mounted in a frame with hinges attached.

- Reduces installation time and ensures proper alignment with door jambs.

- Suitable for renovations or new construction where speed and accuracy are priorities.

Frequently Asked Questions

Q: Can molded doors be used in bathrooms?

A: Yes, if humidity is controlled. Avoid using them in high-moisture or exterior environments unless properly sealed.

Q: What is the difference between hollow core and solid core molded doors?

A: Hollow core doors are lighter and more affordable, while solid core doors are denser, more durable, and provide better sound insulation.

Q: How do molded doors compare to solid wood doors in durability?

A: Molded doors are less durable than solid wood but offer excellent value and consistent appearance at a lower cost.

Summary

Molded doors combine affordability and versatility, making them a smart choice for many indoor spaces. Whether you’re renovating your home, working on a multi-unit housing project, or outfitting commercial interiors, molded doors offer an ideal balance between style, function, and cost-effectiveness. Understanding the strengths of molded doors—like their durability, design flexibility, and low maintenance—can help you make smarter material choices. Got questions about molded doors or want help choosing the right model for your project? Let’s connect—we’re here to help!