Traditional flooring installation is often messy, time-consuming, and labor-intensive. Many property owners struggle with high costs, inconsistent results, and long project timelines. Click flooring has emerged as a modern solution—offering clean, fast installation without adhesives or nails. But what exactly is click flooring, and is it the right system for your space?

Whether you’re a homeowner planning a renovation, a contractor sourcing efficient solutions, or a property manager overseeing unit upgrades, understanding click flooring is essential. This article offers a comprehensive overview of how click flooring works, the materials behind it, its benefits and limitations, and how it compares to traditional flooring systems.

You’ll also learn about installation techniques, material options such as SPC, LVT, and laminate, and recommended use cases across various environments. By the end, you’ll have the insight to decide whether click flooring aligns with your project requirements, budget, and long-term maintenance goals.

What Is Click Flooring?

Click flooring refers to a floating floor system where individual planks or tiles are designed to interlock using a tongue-and-groove mechanism. This installation method eliminates the need for adhesives, nails, or staples, making the system both efficient and user-friendly. It’s most commonly found in resilient flooring types such as Luxury Vinyl Plank (LVP), Luxury Vinyl Tile (LVT), Stone Plastic Composite (SPC), and laminate flooring.

The term “click” comes from the audible snap that occurs when the locking edges of two boards are correctly engaged. Once installed, the flooring behaves as a single continuous surface, floating above the subfloor while remaining stable underfoot. This design allows for rapid installation, reduced labor costs, and ease of replacement—making it a preferred choice for both residential and commercial applications.

Click flooring is particularly valued for its combination of mechanical simplicity and structural integrity, offering a seamless visual finish with minimal installation expertise required. With the growing demand for fast, cost-effective remodeling solutions, click-lock systems have become a dominant standard in the modern flooring industry.

What Is Click Flooring and How Does It Work?

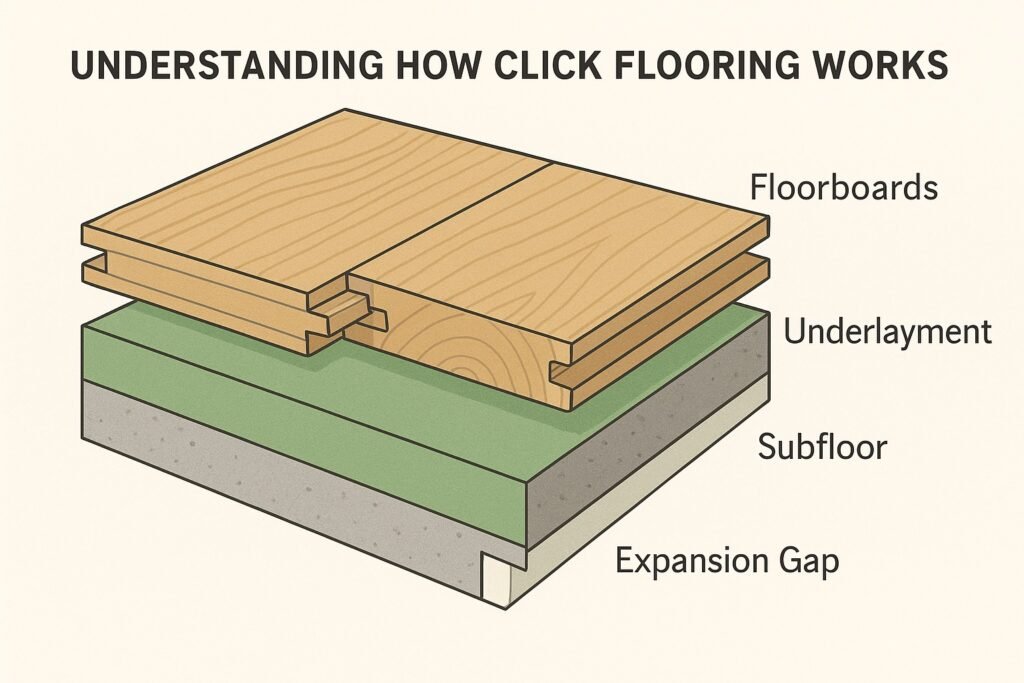

Click flooring operates on a mechanical interlocking system that enables each plank or tile to connect securely to its neighbor without the use of adhesives or nails. The mechanism typically involves a tongue (male edge) on one side and a groove (female edge) on the other. During installation, the tongue is angled into the groove of the adjacent plank and pressed down to “click” into place, forming a tight seam. Once engaged, the flooring behaves as a continuous floating layer across the surface of the room.

This floating installation method brings numerous practical advantages. It allows for installation over most existing subfloors, including plywood, concrete, and even some older flooring surfaces, provided they are level and dry. Additionally, because the floor is not permanently fixed to the subfloor, it can expand and contract naturally with temperature and humidity fluctuations—reducing the risk of warping or buckling.

Click-lock technology is used across several product categories, including:

- LVP (Luxury Vinyl Plank) – Known for water resistance and wood-like finishes

- LVT (Luxury Vinyl Tile) – Typically mimics stone or ceramic tiles

- SPC (Stone Plastic Composite) – Extremely rigid and dimensionally stable

- Laminate Flooring – Wood-based core with a photographic surface layer

Each material category offers distinct performance characteristics, but all share the same easy-to-install click-lock design, making them suitable for fast-paced construction timelines and do-it-yourself renovations alike.

Why Is Click Flooring So Popular Today?

The popularity of click flooring has surged in both residential and commercial markets due to its practical advantages in installation, maintenance, and design flexibility. Below are the key factors driving its widespread adoption:

- ✅ DIY-Friendly — The click-lock system eliminates the need for adhesives or fasteners, enabling homeowners to perform installations without specialized tools or trade skills.

- ✅ Quick Installation — Projects can often be completed in a single day, significantly reducing labor time and project downtime compared to glue-down or nail-in systems.

- ✅ Eco-Conscious — By avoiding adhesives, click flooring reduces volatile organic compound (VOC) emissions, making it a healthier and more environmentally friendly choice.

- ✅ Design Versatility — Available in wood, stone, and ceramic visuals with high-definition printing, click flooring can replicate premium aesthetics at a fraction of the cost.

- ✅ Low Maintenance — Most click flooring products offer wear layers resistant to scuffs, stains, and minor moisture exposure, reducing long-term upkeep.

- ✅ Flexible Applications — Suitable for use over various subfloors in residential, rental, and light commercial environments. Floating installations allow for easier future removal or replacement.

These advantages make click flooring a preferred option not just for budget-conscious homeowners, but also for contractors and developers working under tight schedules or in spaces where fast turnover is critical.

Click Flooring vs Glue-Down and Other Systems

How does click flooring compare with traditional installation systems such as glue-down or nail-down methods? The chart below outlines key differences:

| Feature | Click Flooring | Glue-Down Flooring | Nail-Down / Staple |

|---|---|---|---|

| Installation | DIY-friendly | Professional recommended | Professional required |

| Removal | Reversible | Permanent | Permanent |

| Subfloor Needs | Flat, dry, structurally sound | Smooth, adhesive-ready | Wood subfloor only |

| Common Materials | LVP, SPC, laminate | Vinyl, rubber | Solid hardwood |

| Water Resistance | High (LVT/SPC) | Varies | Low |

While click flooring excels in speed and accessibility, glue-down systems may be preferred in commercial environments where permanent adhesion is critical for durability. Nail-down or staple-down floors, typically used with hardwood, offer a traditional feel but come with higher installation costs and substrate limitations.

It’s also worth noting that drop lock systems—a subtype of click-lock—further simplify the process by allowing boards to lock by simply pressing down, without requiring angling. This feature makes them particularly suitable for DIY applications and large-scale residential rollouts.

What Are the Pros and Cons of Click Flooring?

Click flooring offers a range of technical and practical advantages, but like any system, it also has limitations that must be considered depending on the project type, usage intensity, and site conditions.

Advantages of Click Flooring

- Efficient Installation Process The tongue-and-groove locking mechanism allows for rapid, glue-free installation. This reduces labor time significantly, particularly on time-sensitive or large-scale projects.

- DIY-Friendly Application No adhesives or specialized tools are required, making it suitable for homeowners and small contractors. It is also ideal for occupied spaces where fast turnover is essential.

- Material Versatility Click flooring is available in SPC, LVP, LVT, and laminate formats, offering a wide range of visual styles, wear layers, and core constructions tailored to various applications.

- Durability in Residential Use High-quality click flooring features a protective wear layer that resists abrasion, stains, and impact, suitable for moderate foot traffic in homes and rental properties.

- Compatibility with Radiant Heating Systems Most click flooring products can be installed over in-floor heating systems, provided proper expansion gaps are maintained and manufacturer guidelines are followed.

Limitations and Considerations

- Subfloor Flatness Is Critical Click flooring requires a level substrate (typically within 3/16″ over 10 feet). Uneven subfloors can cause misalignment, hollow sounds, or stress on the locking joints, leading to failure over time.

- Acoustic Performance Without Underlayment Without an acoustic underlayment, click flooring may produce hollow or loud footfall noises. This is particularly noticeable in multi-story or multi-unit buildings where sound transmission is a concern.

- Expansion and Contraction Over Large Areas As a floating system, click flooring expands and contracts with ambient humidity. For installations exceeding 30 linear feet, transition strips or expansion joints may be necessary to prevent buckling.

- Limited Load-Bearing Capacity The mechanical locking system is not designed to handle concentrated static loads (e.g., pianos, large kitchen islands). Excessive weight can cause the joints to decouple or deform under stress.

- Edge Vulnerability in High-Traffic Commercial Spaces In areas subject to heavy rolling loads or frequent impact (e.g., offices, retail), edge wear may occur faster unless a commercial-grade product (e.g., SPC with reinforced core) is selected.

Water resistance also varies by material. SPC and LVT products typically offer full waterproofing, making them suitable for kitchens, bathrooms, and basements. In contrast, laminate click flooring is water-resistant at best and should not be used in areas prone to standing moisture unless explicitly rated for such conditions.

What Materials Are Used in Click Flooring?

Click flooring is available in several core material constructions, each offering specific performance characteristics depending on the use case, budget, and installation environment.

- LVT (Luxury Vinyl Tile): Composed of multiple vinyl layers with a photographic top layer, LVT offers flexibility and moderate impact resistance. It performs well in areas where some moisture is expected, such as kitchens or laundry rooms. Typically ranges from 2 mm to 5 mm in thickness.

- LVP (Luxury Vinyl Plank): A variation of LVT shaped like wood planks. It shares similar structural composition but is often thicker and more rigid, making it ideal for homeowners seeking realistic hardwood visuals with waterproof performance.

- SPC (Stone Plastic Composite): Engineered with a rigid core made from calcium carbonate and stabilizers, SPC click flooring delivers superior dimensional stability, indentation resistance, and sound absorption. Its higher density makes it suitable for high-traffic commercial areas and areas subject to furniture loads.

- Laminate: Constructed from a high-density fiberboard (HDF) core with a decorative top layer, laminate offers an affordable alternative to real wood. However, it lacks true waterproofing and is only water-resistant. Best used in dry, climate-stable environments.

All of these materials use the same click-lock edge system, but SPC and LVP are the most suitable for environments requiring full waterproof performance.

Where Should You Install Click Flooring?

Click flooring can be installed in a variety of spaces, provided that material selection aligns with functional requirements such as humidity levels, traffic load, and structural movement.

- Bedrooms & Living Rooms: Most click flooring products—particularly LVP and laminate—are suitable due to lower foot traffic and minimal moisture exposure.

- Kitchens & Dining Areas: Use only waterproof-rated materials (SPC or LVP). Avoid standard laminate products unless explicitly rated for moisture protection.

- Bathrooms & Laundry Rooms: These areas demand 100% waterproof materials such as SPC or select LVT with sealed locking edges. Always ensure proper sealing at the perimeter to prevent water infiltration.

- Rental Properties & Short-Term Stays (e.g., Airbnb): Click flooring is ideal for fast turnovers, minimal downtime, and cost-effective replacements. Choose SPC for better durability under varying tenant use conditions.

- Light Commercial Environments (e.g., offices, clinics): Commercial-grade SPC with a ≥20 mil wear layer and high static load rating is recommended. Use underlayment rated for sound insulation to comply with building code.

⚠️ Always evaluate substrate preparation, ambient humidity, and expansion requirements before installation to avoid long-term performance issues.

How Do You Install Click Flooring? A Professional Overview

While click flooring is known for its user-friendly nature, proper installation still requires adherence to industry standards to ensure long-term stability and warranty compliance.

Installation Procedure:

- Acclimate the Flooring Store planks in the installation room for 48–72 hours at consistent room temperature (18°C–30°C) to minimize post-installation expansion or contraction.

- Assess and Prepare the Subfloor Ensure it is clean, level (tolerance ≤ 3/16” over 10 ft), dry (≤ 4.5% MC for concrete), and structurally sound. Use leveling compound where necessary.

- Install Underlayment (if required) For laminate or SPC products without pre-attached pads, use underlayment with appropriate acoustic, thermal, and moisture ratings. Vapor barriers are essential over concrete.

- Layout Planning Dry-lay several rows and stagger seams by at least 6–8 inches. Avoid plank lengths under 12 inches near walls.

- Click and Lock Installation Begin along the longest wall. Insert plank tongues into grooves at a 20–30° angle and press down firmly until fully locked. Use spacers to maintain a 6–10 mm perimeter expansion gap.

- Cutting & Trimming Use a miter saw, table saw, or vinyl cutter for precision. Avoid scoring brittle SPC with utility knives.

- Finishing Touches Remove spacers and install baseboards or quarter-rounds. Do not fasten moldings through the flooring surface.

What Is Click Flooring and How Does It Work

Summary

Click flooring combines speed, simplicity, and material diversity in a way that few flooring systems can match. With products ranging from basic laminate to rigid-core SPC, it supports a broad spectrum of residential and light commercial applications. When installed correctly on a prepared subfloor, click flooring offers not just aesthetic value, but also structural performance, moisture protection, and long-term return on investment.