Introduction

Builders face constant pressure to balance cost, durability, and finish quality. MDF base moulding offers a tempting alternative to wood—but is it right for your job site? This guide walks you through what it is, where it works best, and how to choose and install it correctly.

MDF base moulding is a cost-effective trim crafted from engineered wood fibers and resin, offering a smooth, uniform finish that mimics real wood. Pre-primed for easy painting, it eliminates sanding and speeds up installation. Its resistance to warping and humidity makes it ideal for baseboards and casings in both homes and commercial spaces. Durable yet affordable, it provides a polished look without the maintenance of natural wood. Perfect for budget-conscious renovations, it balances aesthetics and practicality seamlessly.

Now that we’ve covered the basics, let’s delve into specific pros and cons, usage tips, and buying advice to explore why MDF is such an outstanding choice for modern interiors.

What are the advantages and disadvantages of MDF moulding?

Advantages of MDF:

- Cost-effective – MDF is cheaper than solid wood and even some plastic alternatives.

- Smooth finish – Ideal for painted finishes; no wood grain or knots.

- Pre-primed – Saves labor time on-site.

- Cuts easily – Great for quick, clean installs using common power tools.

- Consistent – Uniform density and sizing make for predictable results.

Disadvantages of MDF:

- Moisture-sensitive – It absorbs water like a sponge unless sealed correctly.

- Heavy – More weight can make handling on-site slightly harder than pine or PVC.

- Can’t be stained – No grain pattern; only suitable for paint finishes.

- Weaker fastener grip – Doesn’t hold nails or screws as firmly as wood.

- Contains VOCs – MDF includes formaldehyde-based resins. Always wear a mask when cutting.

Is MDF Good for Moulding?

Yes, MDF is a solid choice for moulding in many situations—especially when:

- You plan to paint rather than stain the trim.

- The trim is installed indoors in low-humidity environments.

- You want perfectly smooth, defect-free boards.

- You’re doing high-volume or budget-conscious builds.

But for high-impact zones or wet environments, hardwoods or PVC may be better choices.

What Is MDF Base Moulding Used For?

MDF base moulding is used wherever baseboards and trim are required. Common applications include:

- Baseboards: Installed along the floor where walls meet, providing a clean transition and protecting walls from scuffs.

- Casing: Framing windows and doors to create a polished, finished look while concealing gaps between frames and walls.

- Chair Rail: Positioned horizontally at mid-wall height to add architectural interest, protect walls from chair damage, or define spaces in open layouts.

- Crown Moulding and Wainscoting: When budget-friendly elegance is essential, MDF’s smooth surface and paintability make it ideal for decorative ceiling trim or paneled wall accents.

Builders often prefer MDF for model homes, commercial interiors, and painted trim packages where uniformity and speed matter more than grain aesthetics.

Can MDF Base Moulding Be Used in High-Moisture Areas Like Bathrooms or Basements?

Technically, you can use MDF in bathrooms or basements—but you’ll need to be extra cautious.

DO:

- Choose moisture-resistant (MR) MDF variants if available.

- Seal all edges thoroughly before installation.

- Use caulking where moulding meets floor or wall to keep water out.

DON’T:

- Use regular MDF without protection.

- Install in rooms with poor ventilation or frequent condensation.

Alternative: In bathrooms, many builders opt for pine or composite moulding, which are completely waterproof.

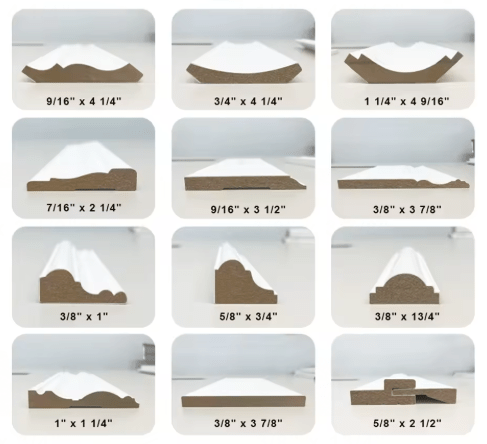

What Sizes and Profiles Are Available for MDF Baseboards?

MDF baseboards are available in a wide range of sizes and styles. Here are some common dimensions and designs:

Popular Sizes:

- 3¼ inch – Basic builder-grade moulding

- 5¼ inch (5 1/2″) – Most common for mid-range homes

- 7¼ inch – Premium or luxury finish

Common Profiles:

- Colonial – Classic curves and traditional look

- Modern/Square edge – Clean, straight lines for contemporary spaces

- Beaded or Stepped – Adds subtle detailing

Most MDF baseboards come pre-primed, ready for paint. Custom profiles can also be ordered from millwork suppliers if you need a unique look for your project.

How Do You Install MDF Base Moulding Properly to Prevent Damage?

Proper installation is crucial to get the best results from MDF base moulding.

Installation Steps:

- Acclimate the moulding – Let MDF adjust to room temp/humidity for 24–48 hrs.

- Cut clean edges – Use a sharp, fine-tooth blade to avoid chipping.

- Seal the ends – MDF edges absorb moisture fast; seal with primer or glue.

- Use adhesive + nails – Combine for stronger hold, especially on uneven walls.

- Fill & caulk – Fill nail holes with wood filler and caulk seams.

- Paint – Always apply a high-quality paint over the primer for long-term protection.

Common Mistakes to Avoid:

- Leaving unprimed edges exposed

- Skipping caulk in corners or at the floor

- Using too much force with nails (can split ends)

Purchase Suggestions: What to Look for When Buying MDF Base Moulding

As a builder, you know not all MDF is equal. Here’s how to choose the right moulding for your job:

What to Look For:

- Pre-primed MDF – Saves on paint time and labor

- High-density core – Better durability, less chance of denting

- Smooth edges – No delamination or fuzzy cuts

Consider This:

- Moisture-resistant MDF – A must for bathrooms or kitchens

- Buy extra – MDF can chip on cuts; 10–15% overage is a safe bet

- Check in-store – Physically inspect boards for bowing or damage

💡 Tip: Don’t mix brands or batches—colors, finishes, or profiles may vary slightly.

Summary

MDF base moulding offers builders an affordable, consistent, and professional-looking solution—if installed and sealed correctly. What’s your experience with MDF trim? Drop your best tips or questions in the comments—we’re building better, together.