Every construction project runs on a tight timeline, and wasted time equals wasted money. If you’re constantly prepping, planing, or squaring rough lumber, you’re working harder than you need to. S4S boards offer a smarter, cleaner alternative—delivered smooth, square, and ready to install. Let’s unpack why builders should pay attention.

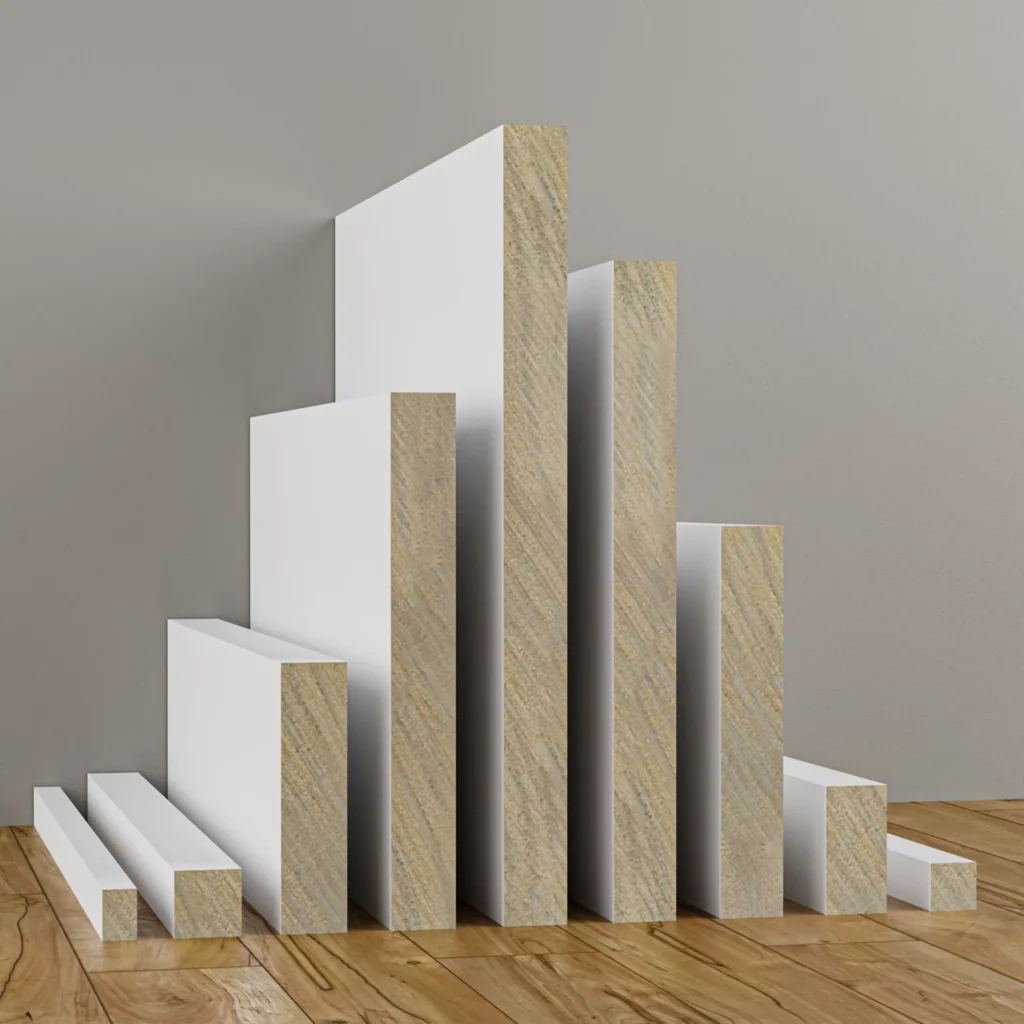

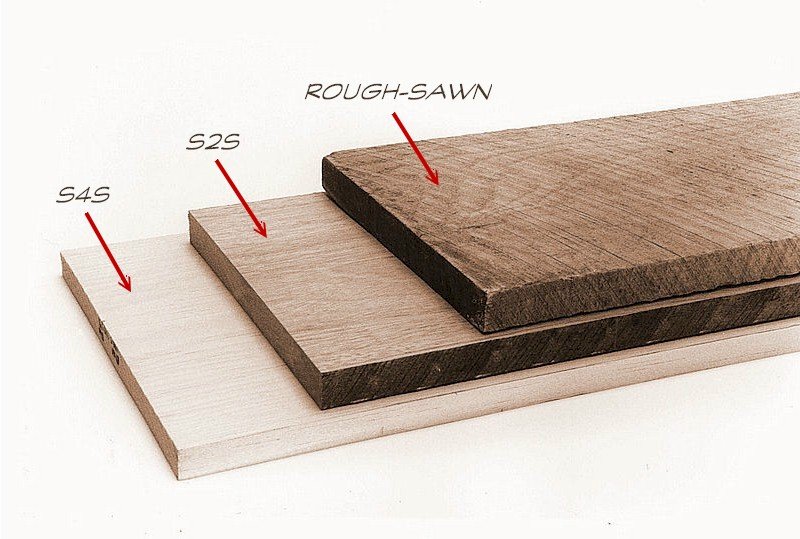

S4S (Surfaced Four Sides) board is lumber meticulously planed on all four surfaces—two faces and two edges—to achieve flawless flatness, squareness, and uniform thickness. Unlike rough-sawn timber, S4S eliminates the need for on-site milling, saving builders hours of labor and reducing material waste. Its precision-engineered dimensionsensure seamless fitting in framing, trim, or furniture projects. Contractors prize S4S for its consistency, which accelerates timelines by 15–20% and minimizes errors. Ideal for both DIY enthusiasts and large-scale builds, S4S bridges the gap between raw wood and flawless finish.

To understand the real value of S4S lumber, we need to go beyond the basics. Let’s explore how it’s produced, when and why to use it, and how it compares to other common boards.

S4S Production Process

S4S boards may look simple on the surface, but there’s a precise process behind that clean appearance. Here’s a deeper look at how they’re made:

Step-by-Step Process:

- Raw Lumber Selection – Boards are kiln-dried and selected for grain and quality.

- Face Planing (S2S) – Both top and bottom faces are planed flat and parallel.

- Edge Surfacing – Edges are straight-line ripped to square the board.

- Sanding – Some S4S boards are lightly sanded for ultra-smooth finishes.

- Grading – Final inspection for warps, knots, and surface consistency.

This results in boards that are ready for immediate use, especially in finish work.

Advantages and Disadvantages of S4S

Advantages

- Saves time and labor

- No need for planers or jointers

- Consistent, uniform dimensions

- Perfect for finish carpentry

- Available in softwood and hardwood varieties

Disadvantages

- Higher cost than rough lumber

- Less control over dimensions

- Can still warp if improperly stored

- Not suited for heavy structural framing

What Are the Common Applications of S4S in Construction?

S4S boards are widely used in both residential and commercial construction, especially in areas where visual finish is key.

Interior Use:

- Trim & moulding

- Cabinetry

- Shelving & built-ins

- Wall treatments (shiplap, wainscoting)

Exterior Use (treated S4S):

- Fascia boards

- Decorative beams

- Deck railings and skirting

S4S Storage and Maintenance

Even pre-milled boards need proper care:

Storage Tips:

- Store flat and off the ground

- Use stickers between layers for airflow

- Keep away from moisture and direct sunlight

- Let boards acclimate to the jobsite before use

Maintenance:

- Light sanding before finishing

- Seal ends to prevent checking

- Inspect for warping before cutting or fastening

Common Mistakes When Working With S4S Lumber

While S4S boards offer convenience and consistency, they’re not mistake-proof. Builders can still run into problems if they treat them like rough stock or forget a few key details.

Mistake 1: Assuming All S4S is Perfectly Straight

Not all S4S is created equal. Boards may have slight warps or twists from storage, transport, or moisture exposure. Always eyeball down the length before cutting or fastening—and keep a straight edge or chalk line handy for double-checking.

Pro Tip: Don’t rely solely on labels. Even if it’s sold as S4S, some boards need minor correction cuts.

Mistake 2: Using Interior S4S for Outdoor Jobs

Many builders assume all S4S is treated—but it’s not. Using untreated S4S outdoors (e.g., for fascia, deck skirting, etc.) will lead to warping, rot, or rapid breakdown.

Always check if the board is pressure-treated or kiln-dried before exterior use.

Mistake 3: Overdriving Nails or Screws

Since S4S edges are pre-milled and smooth, they’re more prone to splitting if you fasten too close to the edge—especially with hardwoods.

Solution: Pre-drill pilot holes or use finish nails + glue for better hold without damage.

Mistake 4: Forgetting to Acclimate Boards

S4S boards, like all wood products, need time to acclimate to indoor humidity—especially before installing as trim or millwork.

Skip this step, and your perfect fit could shrink, swell, or shift after install.

Mistake 5: Not Sealing Exposed Ends

End-grain absorbs moisture quickly. Even indoors, sealing cut ends helps avoid checking or cracks that can show up weeks later.

How S4S Affects Project Timelines (and Why It’s Worth It)

For time-conscious builders and remodelers, S4S isn’t just a convenience—it’s a productivity upgrade. Here’s how it can reshape your schedule:

1. Reduces Milling Time by 80–100%

Since the boards are already:

- Planed

- Ripped

- Smoothed

You skip 2–3 major prep steps. This can save up to 15–30 minutes per board, especially when compared to rough-sawn or S2S lumber.

On a job using 100+ boards, that’s dozens of labor hours reclaimed.

2. Fewer Tools = Faster Setup & Teardown

You don’t need to haul out the jointer, planer, or table saw just to prep your material. That means:

- Less setup time

- Quieter work zones

- Fewer extension cords and dust hoses

Great for finish jobs in occupied homes or tight spaces.

3. Minimizes Material Handling Delays

With rough lumber, you often sort through stacks, trim edges, or re-joint after warping. With S4S, most boards come installation-ready—you simply measure, cut, and install.

4. Fewer Measurement Errors

S4S boards have consistent dimensions (e.g. ¾″ actual thickness, true-width faces), which reduces layout confusion and eliminates trial cuts.

That’s especially useful when building:

- Cabinets

- Framing boxes

- Custom shelving

- Trim returns and reveals

Real-World Impact:

A contractor doing a custom closet build reported saving 6 hours over a 2-day install by switching from S3S to S4S poplar boards.

Multiply that across multiple rooms, and it’s a difference your client notices—and your budget benefits from.

Pro Advice for Builders

When to Use S4S:

- Fast-paced trim and finish jobs

- When working without milling equipment

- In precise installations like cabinetry

- For high-end aesthetic work

Smart Builder Tips:

- Buy longer lengths and cut down

- Check for kiln-dried certification

- Ask about FSC or sustainable options

- Use treated S4S outdoors with proper sealing

Conclusion

S4S boards offer speed, precision, and polish for today’s builder. Whether you’re wrapping up a renovation or crafting high-end trim, they save time without sacrificing quality. Still on the fence? Try S4S on your next job—you might never look back.