In construction today, flooring needs to meet more than design expectations. Builders demand systems that perform under pressure — from foot traffic and climate shifts to installation timelines and warranty requirements. That’s where SPC flooring (Stone Plastic Composite flooring) is making a measurable impact.

SPC flooring is a rigid-core multilayer flooring system made from limestone powder, PVC, and stabilizers. Engineered for dimensional stability, it’s 100% waterproof, click-lock installable, and resistant to compression and expansion — making it ideal for both commercial and residential builds.

In this guide, we’ll explore how SPC is built, where it performs best, how it compares to alternatives like WPC and LVT, and what construction teams should know when specifying or installing it.

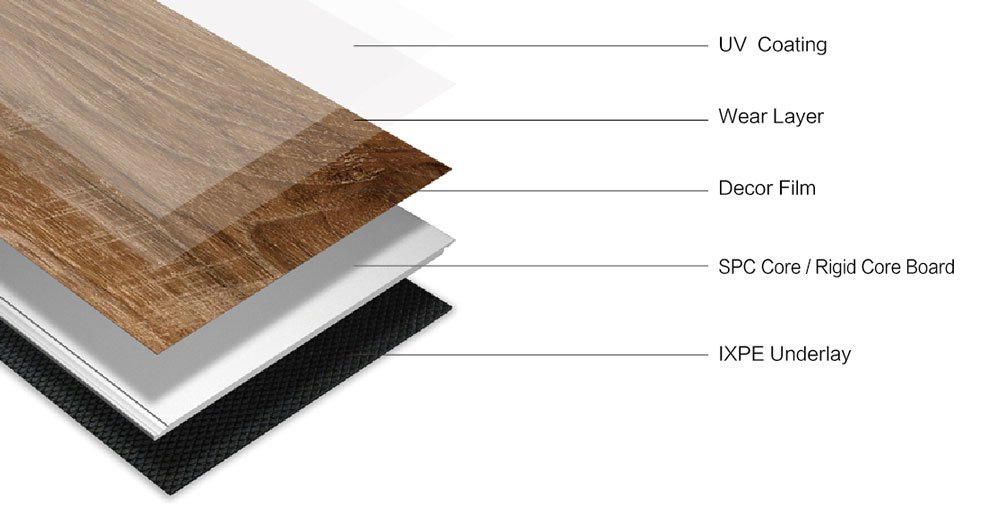

How is SPC Flooring Structured?

SPC flooring is built with a multi-layered structure engineered to meet the rigorous demands of modern construction — especially where moisture resistance, dimensional stability, and fast-track installation are critical.

Here’s a breakdown of the layers:

- UV Coating (Top Finish Layer) A protective coating applied above the wear layer, this finish enhances scratch resistance and protects against fading from UV exposure — especially important in sunlit commercial lobbies or residential spaces with large windows.

- Wear Layer (0.3mm–0.7mm) This transparent layer resists abrasion, scuffing, and staining. In commercial settings, a thicker wear layer (0.5mm or 20 mil+) is standard to withstand rolling loads, foot traffic, and routine maintenance with industrial cleaners.

- Printed Vinyl Film High-resolution printed layer that replicates natural materials like oak, slate, or marble. Advanced technologies such as Embossed-in-Register (EIR) align texture with the printed image, enhancing authenticity.

- SPC Core (Rigid Core Layer) The heart of the system — made from a high-density blend of limestone (60–70%), PVC resin, and stabilizers. This core offers:

- Dimensional stability under thermal expansion (up to ±0.05%)

- Resistance to subfloor irregularities

- Load-bearing strength suitable for commercial footfall (>2000 kg/m³ density)

- Underlayment (Pre-attached IXPE or EVA) Many SPC planks include a factory-attached acoustic backing that provides:

- Sound insulation (STC 60+ with IXPE)

- Minor subfloor correction

- Improved foot comfort

What Are the Common Thickness Options for SPC Flooring?

SPC flooring is available in various thicknesses — both in total plank thickness and wear layer thickness — to suit different installation needs and performance expectations.

🔸 Plank Thickness (Total)

Plank thickness includes the core and all layers above the backing. Here’s how to choose:

| Thickness | Recommended For | Technical Considerations |

|---|---|---|

| 3.2–4.0mm | Light-use residential | Less noise absorption, minimal cushioning |

| 4.2–5.5mm | Standard home/commercial | Balanced rigidity and comfort |

| 6.0mm–8.0mm+ | High-traffic commercial, multi-family | Excellent acoustic insulation and subfloor bridging |

🔹 Wear Layer Thickness

The wear layer sits just beneath the UV topcoat and defines surface durability:

| Wear Layer | Application | Performance |

|---|---|---|

| 0.3mm / 12 mil | Homes, bedrooms | Light-to-moderate wear resistance |

| 0.5mm / 20 mil | Kitchens, offices | Industry-standard for most use cases |

| 0.7mm / 30 mil | Retail, hospitals | Suitable for heavy rolling loads and industrial maintenance routines |

What Are the Main Advantages of SPC Flooring?

SPC flooring isn’t just a vinyl alternative — it’s a structurally engineered product tailored for today’s performance demands. Here’s why it’s increasingly favored by contractors, architects, and developers:

💧 1. 100% Waterproof Core

SPC’s stone-based rigid core ensures zero water absorption — making it safe for kitchens, bathrooms, laundry rooms, and even below-grade basements. Unlike laminate or hardwood, it won’t swell, cup, or delaminate.

📏 2. Dimensional Stability

Thanks to its high limestone content, SPC remains stable across wide temperature and humidity fluctuations. It won’t expand or contract like traditional vinyl — critical for installations near large windows or radiant heat systems.

🦶 3. Dent & Compression Resistance

With a core density exceeding 2000 kg/m³, SPC easily withstands:

- Furniture legs

- Rolling chairs

- High heels

- Impact from dropped tools or equipment

🔧 4. Fast, Clean Installation

Click-lock systems eliminate the need for adhesives, nails, or drying time. Builders can lay up to 1,500 sq. ft. per day with a two-person crew. Pre-attached underlayment simplifies logistics.

🧹 5. Easy Maintenance

No sealing, waxing, or polishing needed. Routine sweeping and mopping with neutral pH cleaners is sufficient — ideal for commercial clients with janitorial contracts.

🧹 6. Design Versatility

SPC planks come in a wide variety of:

- Wood species (oak, maple, hickory)

- Stone and tile visuals (slate, marble)

- Surface textures (hand-scraped, wire-brushed, EIR)

- Plank sizes (standard 6×48” to XL 9×60”)

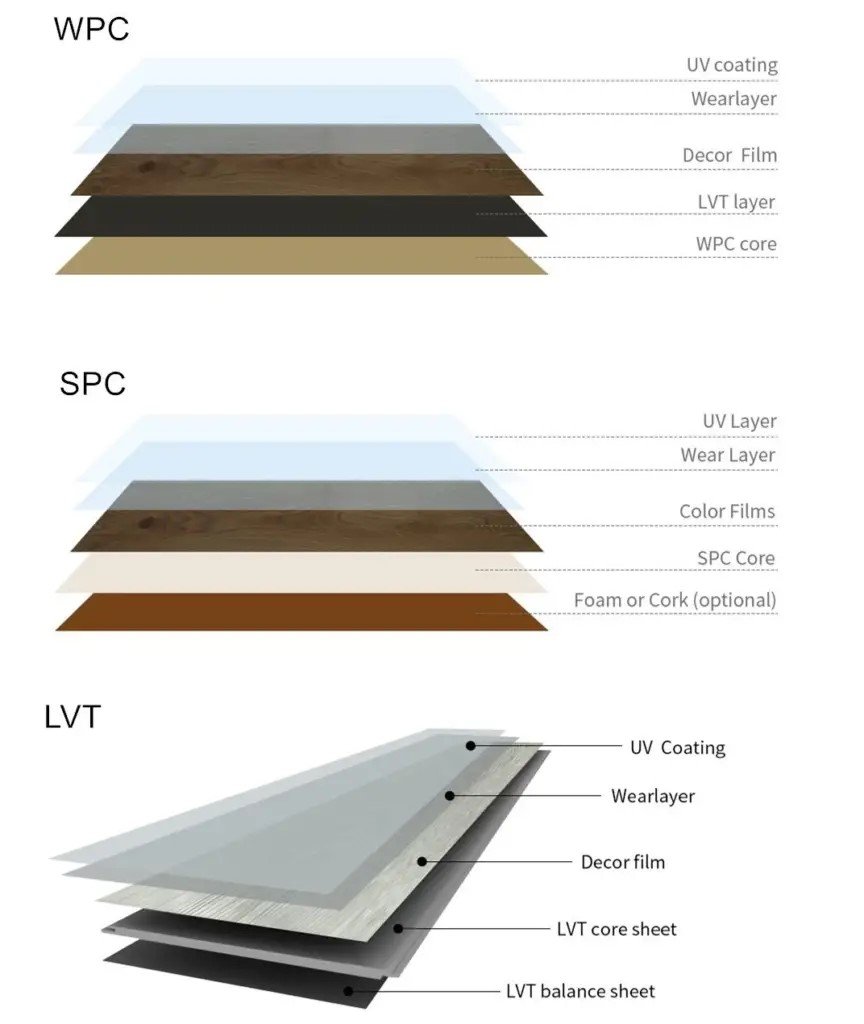

How does SPC compare to LVT and WPC flooring?

| Feature | SPC | LVT | WPC |

|---|---|---|---|

| Core Material | Stone + PVC | Vinyl-only | Wood fiber + PVC |

| Rigidity | Very High | Low | Medium |

| Water Resistance | 100% | High | 100% |

| Comfort Underfoot | Moderate | Soft | Very Soft |

| Installation Type | Floating Click | Glue/Floating | Floating Click |

| Best For | High-traffic, commercial | Low-traffic, decorative | Residential comfort |

Is SPC flooring suitable for commercial vs residential use?

Absolutely. SPC is engineered for commercial-grade durability, while maintaining design flexibility suitable for residential settings.

Residential Uses:

- Bathrooms, basements, kitchens

- Pet-friendly homes

- DIY remodels

Commercial Uses:

- Retail stores, offices, lobbies

- Restaurants, healthcare facilities

- Schools, airports

For commercial jobs, select planks with 20 mil+ wear layer, Class 33/AC5 abrasion ratings, and fire resistance certifications (ASTM E648 / EN 13501-1).

How much does SPC flooring cost?

Prices vary depending on specs, brand, and region:

| Tier | Thickness | Wear Layer | Price (USD/sq ft) |

|---|---|---|---|

| Entry | 3.2mm–4mm | 12 mil | $2.00–$2.75 |

| Mid-Range | 4.5mm–6mm | 20 mil | $2.75–$4.00 |

| Premium | 6.5mm–8mm+ | 22–30 mil | $4.00–$6.00+ |

Installation cost (if not DIY): $1.50–$3.00/sq ft Total Installed Cost Estimate: $3.50–$9.00/sq ft

How to Choose the Right SPC Flooring for Your Project

Selecting the right SPC flooring goes beyond visual design — it requires aligning product specs with real-world usage, performance needs, and installation conditions. Here’s how professional builders should evaluate options:

- Match the Use Case Define whether the space is residential, light commercial, or high-traffic industrial. For example:

- Use entry-level 4mm SPC in bedrooms or rental units

- Go with 6mm+ planks with 20+ mil wear layer for clinics or retail stores

- Specify the Wear Layer The wear layer determines surface durability. Choose:

- 12 mil (0.3mm) for low-traffic home areas

- 20–30 mil (0.5–0.7mm) for busy commercial sites or rolling loads

- Understand Core Density A higher-density core (>2000 kg/m³) offers better resistance to indentation and structural noise. Ask suppliers for technical datasheets to confirm density ratings.

- Select Appropriate Underlayment IXPE and EVA foam backings differ in acoustic performance. Use:

- IXPE for multi-family or upstairs installs (STC/IIC ≥ 60)

- EVA for retail or office where cost-efficiency matters

- Verify Product Certifications Confirm compliance with:

- FloorScore® for VOC emissions

- GREENGUARD Gold for indoor air quality

- ASTM F3261 (North America) or EN ISO 10582 (Europe) for rigid vinyl plank standards

- Prioritize Visual & Surface Texture For high-end installs, select products with:

- Embossed-in-Register (EIR) surfaces for natural texture

- Beveled edges and matte finishes for realistic visuals

What Are the Most Common SPC Flooring Mistakes (and How to Avoid Them)?

Even the best flooring products can fail due to improper installation or poor planning. Below are six common mistakes professionals should avoid — with solutions.

🔧 1. Skipping Subfloor Preparation

Problem: Uneven or unclean subfloors cause hollow sounds, plank separation, or bounce. Solution: Use a self-leveling compound and check for <3mm variation over 3ft span, per ASTM F710 guidelines.

📏 2. Ignoring Expansion Gaps

Problem: SPC planks expand and contract with temperature. Without perimeter gaps (8–10mm), floors buckle or tent. Solution: Leave sufficient expansion space along walls and fixed structures. Use spacers during installation.

💦 3. Using Steam Cleaners or Harsh Chemicals

Problem: Steam and high-pH cleaners break down the wear layer and cause clouding or peeling. Solution: Use only neutral-pH cleaners and avoid wet mops, per manufacturer’s maintenance instructions.

🔇 4. Omitting Acoustic Underlayment in Multi-Unit Projects

Problem: Floors fail STC/IIC testing, causing issues in building code compliance or tenant satisfaction. Solution: Use SPC with pre-attached IXPE and confirm lab-tested STC ≥ 62, IIC ≥ 60.

🎨 5. Prioritizing Looks Over Performance Specs

Problem: Choosing a design without checking wear layer, density, or locking strength leads to failure in high-demand areas. Solution: Always match spec sheets to the intended use case — not just the color or texture.

📐 6. Overlooking Height Transitions

Problem: SPC planks with underlayment may sit higher than adjacent flooring, causing trip hazards or door clearance issues. Solution: Plan transitions with reducers or ramp profiles, and pre-check total flooring height.

🛠️ Final Tip: Always follow the manufacturer’s installation guidelines — they’re often required to maintain warranty validity.

Conclusion

SPC flooring brings together material science and field-tested performance — offering a resilient, waterproof, and low-maintenance solution for today’s construction demands. Its dense core, fast installation system, and dimensional stability make it a go-to choice for professionals working across commercial, residential, and multi-use developments.

Whether you’re specifying for a healthcare facility, retrofitting retail space, or managing a multi-unit housing project, SPC provides the reliability and flexibility modern builds require.

Want to ensure your flooring specs meet both performance and project timelines? Explore how SPC can fit into your material strategy — and deliver lasting results.